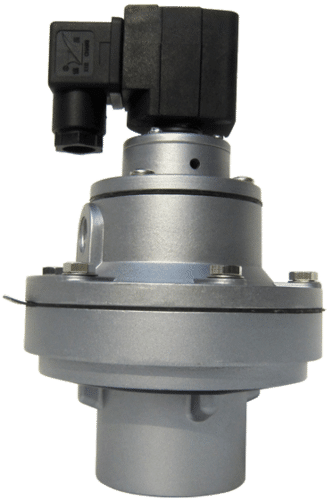

Dust Collector Solenoid Valve

Dust Collector Solenoid Valve Specification

- Surface Treatment

- Anodized Finish

- Air Consumption

- Low (optimized for dust collector applications)

- Pattern Dimensions

- Standard

- Capacity

- Suitable for large-scale filtration systems

- Thread size

- 1 inch (BSP/NPT options)

- Operating Pressure

- 0.5 - 8 bar

- Diameter

- 25mm, 40mm, 50mm (as per model)

- Air Inlet

- G Threaded or Flanged

- Pressure

- 0.5 - 8 Kg/cm

- Product Type

- 2 Way Pulse Jet Solenoid Valve

- Material

- Aluminum Alloy Body, Nitrile Rubber Diaphragm

- Metals Type

- Aluminum

- Usage

- Industrial Dust Collectors

- Size

- 1 inch, 1.5 inch, 2 inch (available options)

- Weight

- 450 grams

- Medium

- Compressed Air

- Port Connection

- Threaded or Flanged as per requirement

- Isolation

- Electrical encapsulated coil for insulation and improved safety

- Response Time

- <50 ms

- Coil Voltage Options

- 24V DC, 110V AC, 220V AC

- Temperature Range

- -20°C to +85°C

- Seal Material

- Nitrile/NBR Rubber

- Diaphragm Type

- Twin/Dual Layer reinforced for durability

- Mounting Position

- Any

- Body Construction

- Pressure die-cast aluminum

- Application

- Pulse jet air cleaning in bag filter units

Dust Collector Solenoid Valve Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Western Union, Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1000 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Western Europe, Australia, North America, Middle East, Central America, South America, Asia, Eastern Europe, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Dust Collector Solenoid Valve

Dust Collector Solenoid Valvedust collector solenoid valve reflects in: Sensitive and reliable signal, Low internal-resistance, Large gas-displacement, High airflow impact-force, Stable working, Long operating-life.

Versatile Coil Voltage and Reliable Operation

This solenoid valve accommodates three coil voltage options-24V DC, 110V AC, and 220V AC-ensuring compatibility with a wide array of industrial electrical systems. The electrical coil is encapsulated for enhanced safety and insulation. The valve's quick response time facilitates efficient pulse cleaning cycles, optimizing filter performance and prolonging operational life.

Durable Construction and Tailored Fit

Built with a pressure die-cast aluminum body and a nitrile rubber diaphragm, the valve excels in industrial environments. Available in 1 inch, 1.5 inch, and 2 inch port sizes and suitable for both threaded and flanged connections, it meets the dimensional and installation needs of various dust collector setups. The anodized finish provides corrosion resistance for long-term reliability.

FAQ's of Dust Collector Solenoid Valve:

Q: How is the Dust Collector Solenoid Valve installed in a bag filter unit?

A: The valve can be mounted in any position, and its flexible design supports threaded (BSP/NPT) or flanged port connections. This allows for straightforward integration into both new and existing dust collector pipeline configurations.Q: What are the benefits of using a twin-layer reinforced nitrile rubber diaphragm?

A: The twin/dual-layer nitrile (NBR) diaphragm ensures enhanced durability and airtight sealing under pressure, reducing maintenance and delivering reliable pulse jet operation over a wide temperature range (-20C to +85C).Q: When should I choose between different coil voltages (24V DC, 110V AC, 220V AC)?

A: Select the coil voltage that matches your facility's electrical supply for optimal safety and efficiency. These options cater to both industrial DC and AC power sources widely available in India.Q: Where is this solenoid valve best utilized?

A: These valves are designed for use in industrial dust collectors, particularly in pulse jet air cleaning for bag filter units, making them essential for manufacturing, processing, and bulk material handling facilities.Q: What is the recommended pressure range for the solenoid valve?

A: The valve operates efficiently within a pressure range of 0.5 to 8 Kg/cm2 (0.5 to 8 bar), suiting most industrial compressed air systems involved in dust collection.Q: How does the quick response time of the valve benefit pulse jet systems?

A: With a response time of less than 50 ms, the valve delivers rapid and precise pulses of compressed air, maximizing cleaning effectiveness and filter regeneration frequency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spray Nozzle Category

Penumatic Diaphargm Valve

Usage : Industrial Fluid Control

Material : Polypropylene & Stainless Steel

Surface Treatment : Polished

Pressure : PN10

Size : DN15 to DN100

AIR ATOMIZING NOZZLES FLAT JET / FULL CONE

Minimum Order Quantity : 01

Usage : Industrial Spray Applications

Material : Brass / Stainless Steel

Surface Treatment : Nickel Plated / Polished

Pressure : 2 to 7 bar

Size : 1/4 inch, 3/8 inch, 1/2 inch

SS Spray Ball

Usage : CIP Cleaning (CleaninPlace) for tanks, vessels, and reactors

Material : Stainless Steel (SS304/SS316)

Surface Treatment : Polished Finish

Pressure : 13 bar

Size : 1/2 inch to 2 inch

Globe Valve

Usage : Industrial Fluid Control

Material : Cast Iron

Surface Treatment : Paint Coated

Pressure : 16 bar

Size : 2 inch

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry