AIR ATOMIZING NOZZLES FLAT JET / FULL CONE

AIR ATOMIZING NOZZLES FLAT JET / FULL CONE Specification

- Capacity

- 0.30 - 8.50 LPH (Liquid flow)

- Surface Treatment

- Nickel Plated / Polished

- Pattern Dimensions

- Flat Jet / Full Cone: 6090 spray angle

- Air Inlet

- BSP/NPT Threaded

- Pressure

- 2 to 7 bar

- Thread size

- 1/4, 3/8, or 1/2 BSP/NPT

- Operating Pressure

- 36 bar (recommended)

- Diameter

- 0.5 mm to 3.0 mm Orifice

- Air Consumption

- 70 to 300 L/min (Varies by model)

- Product Type

- Air Atomizing Nozzle

- Material

- Brass / Stainless Steel

- Metals Type

- Brass / Stainless Steel

- Usage

- Industrial Spray Applications

- Size

- 1/4 inch, 3/8 inch, 1/2 inch

- Weight

- Approx. 75 g

- Mounting Type

- Threaded, Panel Mount

- Operating Media

- Air + Liquid

- Application

- Dust Suppression, Humidification, Coating, Cooling

- Liquid Inlet Size

- 1/4" BSP/NPT

- Available Finishes

- Electroless Nickel, Passivated Stainless

- Adjustment

- Internal / External Mixing

- Max Temperature

- Up to 300°C (depends on material)

- Maintenance

- Easy to disassemble and clean

- Spray Pattern

- Flat Jet / Full Cone

- Nozzle Type

- Two-fluid Air Atomizing

AIR ATOMIZING NOZZLES FLAT JET / FULL CONE Trade Information

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 200 Per Month

- Delivery Time

- 200 Years

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- WOODEN BOX

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2008 MSME

About AIR ATOMIZING NOZZLES FLAT JET / FULL CONE

Spray Angle | Flow rate lpm at pressure P = 2 bar | Connection | Materials |

150, 200, 250, 300, | 0.05 to 6 | 1/4" BSP (F) |

BRASS, SS 304, |

Efficient Atomization for Industrial Applications

Engineered for demanding environments, these spray nozzles utilize air and liquid to deliver consistent and customizable flat jet or full cone spray patterns. Their versatility suits dust suppression, coating, and cooling tasks, making them ideal for manufacturing and processing plants.

Flexible Design and Material Choices

Available in brass or stainless steel with nickel-plated or polished finishes, these nozzles fit threaded or panel mounts, and offer easy disassembly for cleaning. Multiple inlet and thread sizes ensure compatibility with your piping and mounting requirements.

FAQs of AIR ATOMIZING NOZZLES FLAT JET / FULL CONE:

Q: How do air atomizing nozzles achieve fine spray patterns for dust suppression or humidification?

A: Air atomizing nozzles blend compressed air and liquid through internal or external mixing, producing finely atomized sprays. The process ensures uniform coverage, which is critical for dust suppression, humidification, or coating tasks across industrial environments.Q: What is the recommended operating pressure range for these air atomizing nozzles?

A: The recommended operating pressure is between 3 and 6 bar. This ensures optimal atomization performance and consistent spray coverage for flat jet or full cone patterns during industrial usage.Q: When should I use flat jet versus full cone spray patterns?

A: Flat jet patterns are ideal for linear coverage in applications like coating or narrow dust suppression, while full cone patterns suit broader area spraying, such as humidification or cooling large surfaces.Q: Where can these nozzles be installed in an industrial setup?

A: These air atomizing nozzles can be mounted on threaded or panel-mount fixtures, making them suitable for incorporation in spray bars, cooling tunnels, dust suppression systems, and process lines.Q: How easy is it to maintain and clean these nozzles?

A: The nozzle design is optimized for maintenance, allowing simple disassembly and reassembly. This facilitates regular cleaning to prevent clogging or performance issues over time.Q: What benefits do these nozzles offer compared to single-fluid spray nozzles?

A: Two-fluid air atomizing nozzles provide finer atomization and better spray control than single-fluid types, leading to more efficient use of liquid, improved coverage, and enhanced process results in humidification, coating, and cooling.Q: What materials and finishes are available, and how do they impact durability?

A: Nozzles are available in brass or stainless steel, with finishes like electroless nickel or passivated stainless. These material options offer excellent resistance to corrosion and high temperatures, enhancing product lifespan, especially in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spray Nozzle Category

Penumatic Diaphargm Valve

Material : Polypropylene & Stainless Steel

Product Type : Pneumatic Diaphragm Valve

Usage : Industrial Fluid Control

Size : DN15 to DN100

Diameter : 15 mm to 100 mm

Operating Pressure : Up to 10 bar

Pneumatic Butterfly Valve

Material : Cast Iron / Stainless Steel / Aluminum Alloy

Product Type : Pneumatic Butterfly Valve

Usage : Industrial automation, water treatment, chemical processing

Size : 2 inch to 16 inch

Diameter : 50 mm to 400 mm

Operating Pressure : 48 bar

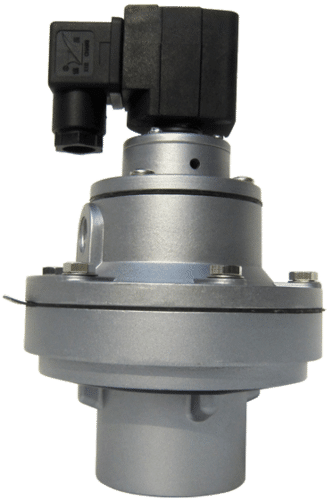

Dust Collector Solenoid Valve

Material : Aluminum Alloy Body, Nitrile Rubber Diaphragm

Product Type : 2 Way Pulse Jet Solenoid Valve

Usage : Industrial Dust Collectors

Size : 1 inch, 1.5 inch, 2 inch (available options)

Diameter : 25mm, 40mm, 50mm (as per model)

Operating Pressure : 0.5 8 bar

FULL CONE NOZZLE

Material : Brass

Product Type : Full Cone Nozzle

Usage : Industrial Spraying, Water Cooling, Dust Suppression

Size : 1/4 inch

Diameter : 10 mm

Operating Pressure : 35 Bar

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry