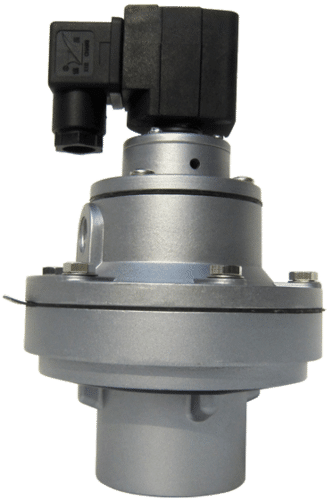

Penumatic Diaphargm Valve

Penumatic Diaphargm Valve Specification

- Capacity

- Up to 30 m/hr

- Operating Pressure

- Up to 10 bar

- Pattern Dimensions

- As per DIN standard

- Pressure

- PN10

- Air Inlet

- 1/4 BSP

- Diameter

- 15 mm to 100 mm

- Surface Treatment

- Polished

- Thread size

- Customized

- Air Consumption

- 0.05-0.1 m/min

- Product Type

- Pneumatic Diaphragm Valve

- Material

- Polypropylene & Stainless Steel

- Metals Type

- SS 304/316

- Plastic Type

- PPH

- Usage

- Industrial Fluid Control

- Size

- DN15 to DN100

- Weight

- 3.5 kg

- Seal Material

- EPDM/PTFE

- Media

- Acids, alkalis, water and slurries

- Temperature Range

- -10°C to +80°C

- Indicator

- Open/Close visual position indicator

- Valve Design

- Weir Type

- Leakage Rate

- Zero leakage (bubble tight)

- Control Signal

- 4-7 bar air pressure

- Actuator Type

- Double Acting Pneumatic

- End Connection

- Flanged/BSP Threaded

- Mounting Position

- Any

- Body Color

- Grey

Penumatic Diaphargm Valve Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Telegraphic Transfer (T/T), Western Union, Paypal, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1000 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Africa, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Penumatic Diaphargm Valve

Pneumatic diaphragm valve

We are a trusted manufacturer and supplier of top grade Pumps and Process Control Instruments. With a premier aim to cater to the varied demands and requirements of our client in an efficient manner, we offer a comprehensive array of products comprising Transfer Pump, Polypropylene Pump, Stainless Steel Self Priming Pump, Filter Pump, Magnetic Drive Pump, Dosing Pump and Process Control Instruments. All these products are developed in compliance with the international quality standards.

Our firm has crossed milestones of success in the industry by offering quality products that are known for an optimal functionality and long service life. The professionals employed by our firm use the latest technological advancements to fabricate all our products. Apart from this, we provide prompt after sales support, installation training, onsite support and operational training. Further, we are backed by a wide distribution network that assists us to provide prompt deliveries of consignments to our clients.

Reliable Valve Performance for Demanding Applications

Engineered for industrial environments, this pneumatic diaphragm valve ensures bubble-tight sealing for precise fluid control. Its robust construction using PPH and stainless steel resists corrosive media, while the double acting pneumatic actuator and wide temperature range maximize operational versatility. The weir-type valve design offers superior shutoff performance, essential for processes handling hazardous fluids.

Flexible Installation and Maintenance

With mounting compatibility in any position and indicator for visual status, the valve simplifies operation and maintenance. The polished finish, as per DIN pattern dimensions, facilitates easy cleaning and durability. Its flanged and threaded (BSP) connections make for hassle-free integration into new or existing pipeline systems.

FAQ's of Penumatic Diaphargm Valve:

Q: How is the pneumatic diaphragm valve operated?

A: The valve uses a double acting pneumatic actuator, controlled by a 4-7 bar air pressure signal. This actuator responds to the supplied air, moving the diaphragm to open or close as required for process automation.Q: What types of fluids can the valve handle effectively?

A: It is specifically designed for acids, alkalis, water, and slurries, making it suitable for a wide range of industrial fluid control applications requiring chemical resistance and reliable shutoff.Q: Where can this valve be installed?

A: The valve is mountable in any position and features a flanged or BSP threaded end connection, allowing installation in various industrial piping systems-new or retrofit-across different sectors and environments.Q: What is the leakage rate and how does it benefit my process?

A: This valve provides zero leakage, offering bubble-tight sealing that prevents any fluid escape and ensures safety, regulatory compliance, and operational efficiency.Q: When should you choose EPDM vs PTFE seal material?

A: EPDM is best for water and mild chemicals, while PTFE should be used for aggressive media, including concentrated acids and alkalis. Select the seal based on specific process media requirements.Q: What is the process for integrating the valve into a system?

A: Installation involves connecting the valve using either flanged or BSP threaded ends, supplying control air to the 1/4 BSP inlet, and adjusting mounting position as needed. The open/close indicator helps verify correct operation during commissioning.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spray Nozzle Category

Pneumatic Butterfly Valve

Pressure : PN10 / PN16

Operating Pressure : 48 bar

Pattern Dimensions : To ISO 5211

Capacity : Full Port

Product Type : Pneumatic Butterfly Valve

AIR ATOMIZING NOZZLES FLAT JET / FULL CONE

Minimum Order Quantity : 01

Pressure : 2 to 7 bar

Operating Pressure : 36 bar (recommended)

Pattern Dimensions : Flat Jet / Full Cone: 6090 spray angle

Capacity : 0.30 8.50 LPH (Liquid flow)

Product Type : Air Atomizing Nozzle

Dust Collector Solenoid Valve

Pressure : 0.5 8 Kg/cm

Operating Pressure : 0.5 8 bar

Pattern Dimensions : Standard

Capacity : Suitable for largescale filtration systems

Product Type : 2 Way Pulse Jet Solenoid Valve

FULL CONE NOZZLE

Minimum Order Quantity : 01

Pressure : 27 Bar

Operating Pressure : 35 Bar

Pattern Dimensions : Conical Spray Pattern

Capacity : 12100 L/min

Product Type : Full Cone Nozzle

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry