Globe Valve

Globe Valve Specification

- Surface Treatment

- Paint Coated

- Pressure

- 16 bar

- Capacity

- High Flow

- Operating Pressure

- 10-16 bar

- Thread size

- BSP Threaded Ends

- Pattern Dimensions

- Standard ASME

- Diameter

- 50 mm

- Product Type

- Globe Valve

- Material

- Cast Iron

- Metals Type

- Cast Iron

- Usage

- Industrial Fluid Control

- Size

- 2 inch

- Weight

- 2.1 Kg

- Service

- Water, Oil, Gas, Steam

- Trim Material

- Stainless Steel

- Working Temperature

- Up to 220°C

- Port

- Full Port

- Standards

- IS 14846/BS 1873

- End Connection

- Flanged

- Seat Type

- Renewable Seat

- Body Material Grade

- IS 210 FG 200

- Bonnet

- Bolted Bonnet

- Color

- Blue

- Stem Type

- Rising Stem

- Handwheel

- Cast Iron

- Leakage Class

- Class VI

Globe Valve Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Paypal, Western Union, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1000 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Asia, Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Globe Valve

FORGED STEEL GLOBE VALVE CLASS 800, 900, 1500.

Forged Steel Globe Valve, Bolted Bonnet, Outside Screw & Yoke, Rising Stem, Non-Rising handwheel. Regular & Full port, Threaded and Socket Weld ends.

- Body : ASTM A105

- Bonnet : ASTM A105

- Seat Ring : A276-410+ STL

- Wedge : ASTM A276-420

- Stem : ASTM A276-410

- Bonnet Bolt : ASTM A193 B7

- Packing : Grafoil

- Gland : ASTM A276-410

- Valve Size : 1 , 1-1/ 4 , 1-1/ 2-2

- Working Pressure : Carbon Steel Class : 800 = 1975 p.s.i @ 100° F / 38° C

- Working Pressure : Carbon Steel Class : 1500 = 3705 p.s.i @ 100° F / 38° C

- Working Pressure : Carbon Steel Class : 2500 = 6105 p.s.i @ 100° F / 38° C

- Gasket : 304 + Graphite

- Gland F; ange : ASTM A216 WCB

- Eye Bolt : ASTM A276-410

- Eye Bolt Nut : ASTM A194 2H

- Eye Bolt Pin : ASTM A276-410

- Steam Nut : ASTM A108-1020

- Handwheel : ASTM A197

- Name Plate : Stainless Steel

Note : Other Valve Material Composition are Variable

Superior Industrial Fluid Control

Engineered for versatility, this globe valve is ideal for controlling water, oil, gas, and steam across a range of industrial settings. With a full port and high-flow capacity, it minimizes pressure loss, making it highly efficient for demanding operations. Its durable cast iron body and precise trim ensure long-term performance and reliability, even during frequent operation.

Built for Enduring Performance

Designed to withstand high temperatures up to 220C and pressures up to 16 bar, this globe valve features advanced components such as a stainless steel trim, renewable seat, and bolted bonnet. The rising stem mechanism ensures clear visual indication of valve status, while the blue paint-coated finish enhances corrosion resistance for extended service life.

FAQ's of Globe Valve:

Q: How is the globe valve installed and where is it typically used?

A: The globe valve is installed using its flanged ends, which are bolted to compatible pipe flanges. It is typically used in industrial fluid control systems involving water, oil, gas, or steam, especially where precise regulation and high flow are required.Q: What are the main benefits of the full port and renewable seat features in this valve?

A: A full port ensures maximum flow capacity with minimal pressure drop, which is vital for efficient operation. The renewable seat allows for easy maintenance; you can replace just the seat rather than the whole valve, extending operational life.Q: When should I choose a valve with a bolted bonnet and stainless steel trim?

A: A bolted bonnet provides a strong seal for high-pressure and high-temperature applications, while stainless steel trim enhances resistance to corrosion and wear. Choose such a valve when durability and maintenance flexibility in demanding conditions are priorities.Q: What standards does this globe valve comply with and why is this important?

A: The valve complies with IS 14846 and BS 1873 standards, which are recognized benchmarks for quality, safety, and reliability in industrial valves. Compliance ensures the valve meets stringent industry requirements for performance and durability.Q: How does the rising stem and handwheel mechanism improve valve operation?

A: The rising stem provides a clear visual indication of the valve's open or closed position, enhancing operational safety. The durable cast iron handwheel ensures smooth manual operation and withstands regular industrial use.Q: Where can I purchase or source this globe valve in India?

A: This globe valve is available through various channels across India, including dealers, distributors, exporters, fabricators, manufacturers, retailers, suppliers, traders, and wholesalers, making sourcing convenient for different procurement needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spray Nozzle Category

Pneumatic Butterfly Valve

Diameter : 50 mm to 400 mm

Usage : Industrial automation, water treatment, chemical processing

Size : 2 inch to 16 inch

Product Type : Pneumatic Butterfly Valve

Pattern Dimensions : To ISO 5211

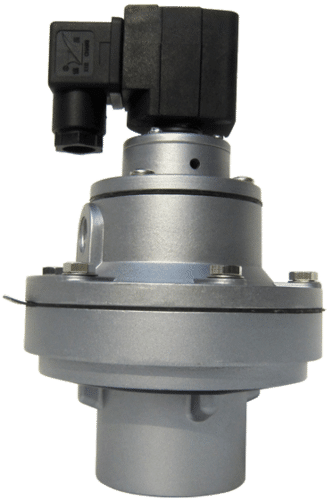

Dust Collector Solenoid Valve

Diameter : 25mm, 40mm, 50mm (as per model)

Usage : Industrial Dust Collectors

Size : 1 inch, 1.5 inch, 2 inch (available options)

Product Type : 2 Way Pulse Jet Solenoid Valve

Pattern Dimensions : Standard

SS Spray Ball

Diameter : 25 mm to 63 mm

Usage : CIP Cleaning (CleaninPlace) for tanks, vessels, and reactors

Size : 1/2 inch to 2 inch

Product Type : Spray Ball

Pattern Dimensions : Full 360degree spray

FULL CONE NOZZLE

Minimum Order Quantity : 01

Diameter : 10 mm

Usage : Industrial Spraying, Water Cooling, Dust Suppression

Size : 1/4 inch

Product Type : Full Cone Nozzle

Pattern Dimensions : Conical Spray Pattern

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry