SS Spray Ball

SS Spray Ball Specification

- Surface Treatment

- Polished Finish

- Diameter

- 25 mm to 63 mm

- Air Inlet

- BSP/NPT Threaded

- Operating Pressure

- 0.5-4 bar

- Pattern Dimensions

- Full 360-degree spray

- Capacity

- Suitable for tanks up to 20,000 Liters

- Thread size

- 1/2 BSP/NPT

- Pressure

- 1-3 bar

- Product Type

- Spray Ball

- Material

- Stainless Steel (SS304/SS316)

- Metals Type

- Stainless Steel

- Usage

- CIP Cleaning (Clean-in-Place) for tanks, vessels, and reactors

- Size

- 1/2 inch to 2 inch

- Weight

- 220-400 grams

SS Spray Ball Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Western Union, Paypal, Letter of Credit (L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About SS Spray Ball

The SS spray ball is a simple yet a highly effective device for the internal washing of process and storage tanks. A spray ball, powered by the cleaning fluid, generates a high pressure spray to clean every part of the vessel. There is only one moving part and no maintenance whatsoever . No lubrication is necessary which prevents any risk of oil or grease contamination of the product, making the spray ball ideally suited for hygiene sensitive applications. These versatile units operate with a wide variety of chemicals and detergents frequently in hostile environments and temperatures upto 120 deg. C and water pressures around 2. 8 kg/cm2 area of vessel coverage can be 1. 5 meter to 3 meter. Spray balls are made of high grade stainless steel aisi 316. End connections are tri-clamp 1 or 1 spray ball are in two designs viz. Multiple nozzle designSS SPRAY BALL

Reliable Performance for Industrial CIP Cleaning

Engineered to meet the stringent standards of food, pharmaceutical, beverage, chemical, and dairy processing, the SS Spray Ball ensures optimal cleaning with precise spray coverage. Its robust stainless steel construction, available in SS304 and SS316, delivers long-term corrosion resistance and exceptional durability, suitable for demanding environments. The device efficiently cleans tanks of various sizes with minimum effort and maintenance requirements.

Versatile Design and Simple Integration

With spray coverage options of 360, 180, or tailored patterns, the SS Spray Ball adapts to unique cleaning needs. Its compatibility with welded or threaded connections, multiple sizes, and a range of operating pressures allows seamless integration into existing CIP systems. The polished finish enhances hygiene while the low weight (220-400 grams) eases handling and installation.

FAQ's of SS Spray Ball:

Q: How does the SS Spray Ball ensure effective cleaning in tanks and reactors?

A: The SS Spray Ball provides thorough CIP cleaning by distributing a consistent spray pattern-360, 180, or custom-ensuring all internal surfaces are covered. With flow rates of 8 to 50 LPM, it delivers robust coverage even for tanks up to 20,000 liters, effectively removing residues and contaminants.Q: What are the installation options and connection types for the SS Spray Ball?

A: You can install the SS Spray Ball using either threaded (BSP/NPT) or welded connections with available sizes from 1/2 inch to 2 inch. This flexibility allows integration into a variety of tank configurations in industries such as food, pharmaceuticals, and chemicals.Q: Where is this spray ball most commonly used?

A: SS Spray Balls are widely used in food processing, pharmaceutical production, chemical plants, dairy facilities, and beverage manufacturing-essentially any location requiring reliable, hygienic, in-place cleaning of tanks or vessels.Q: What is the maintenance process for the SS Spray Ball?

A: The SS Spray Ball requires minimal maintenance due to its polished stainless steel surface, which prevents residue buildup and corrosion. Routine inspection and occasional cleaning of the spray orifices are recommended to maintain optimal performance.Q: What are the main benefits of using an SS Spray Ball in CIP cleaning systems?

A: Key benefits include high corrosion resistance, excellent spray coverage, low maintenance, reliable performance at temperatures up to 120C, and the ability to clean large tanks efficiently. The polished stainless steel construction also enhances cleanliness and durability.Q: When should I consider custom spray coverage or patterns?

A: Custom spray patterns are advisable when standard 360 or 180 coverage does not meet your tank's specific internal configuration or cleaning requirements. Customization ensures targeted cleaning, optimizing your CIP process for unique setups.Q: What materials and surface treatment options are available for the spray ball?

A: The spray ball is available in SS304 or SS316 stainless steel with a polished finish, which supports hygiene, reduces product contamination risk, and increases resistance to aggressive cleaning agents or high temperatures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spray Nozzle Category

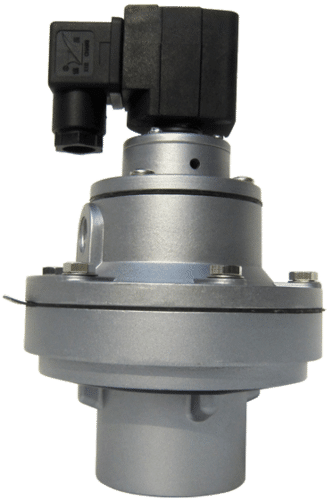

Dust Collector Solenoid Valve

Material : Aluminum Alloy Body, Nitrile Rubber Diaphragm

Surface Treatment : Anodized Finish

Size : 1 inch, 1.5 inch, 2 inch (available options)

Usage : Industrial Dust Collectors

Product Type : 2 Way Pulse Jet Solenoid Valve

FULL CONE NOZZLE

Minimum Order Quantity : 01

Material : Brass

Surface Treatment : Nickel Plated

Size : 1/4 inch

Usage : Industrial Spraying, Water Cooling, Dust Suppression

Product Type : Full Cone Nozzle

Globe Valve

Material : Cast Iron

Surface Treatment : Paint Coated

Size : 2 inch

Usage : Industrial Fluid Control

Product Type : Globe Valve

Industrial Spray Nozzles

Minimum Order Quantity : 01

Material : Brass, Stainless Steel

Surface Treatment : Nickel Plated / Polished

Size : 1/4 inch, 1/2 inch, 3/4 inch

Usage : Industrial spraying applications

Product Type : Industrial Spray Nozzle

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry