Condensate, Seal Pots

Condensate, Seal Pots Specification

- Operating Pressure

- Max 6000 PSI

- Capacity

- 1 to 10 litres

- Thread size

- 1/2 NPT, BSP or as specified

- Surface Treatment

- Polished/Sand Blasted

- Pattern Dimensions

- Custom as per requirement

- Diameter

- 51 mm to 100 mm

- Pressure

- Up to 6000 PSI

- Product Type

- Condensate Seal Pot

- Material

- Stainless Steel (SS 304/316), Carbon Steel

- Metals Type

- Stainless Steel, Carbon Steel

- Usage

- Steam pipeline application, protection of instrumentation

- Size

- 2 inch to 8 inch

- Weight

- Approx 2.5 kg

- Application

- Used in Instrumentation lines for separating condensate from steam

- Thickness

- 3 mm to 8 mm

- Standards

- ASTM, DIN, JIS, IS

- Temperature Range

- -20°C to +425°C

- End Connections

- Butt Weld, Socket Weld, Flanged, Threaded

- Welding Standards

- ASME Section IX

- Test Pressure

- Hydro tested at 1.5x design pressure

- Mounting Type

- Vertical or Horizontal

Condensate, Seal Pots Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Western Union, Paypal, Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, South America, Eastern Europe, Middle East, Africa, Western Europe, Central America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Condensate, Seal Pots

Seal / Condensate pots are used as part of instrumentation piping in all those applications where a direct contact of the sensing elements with process media is not recommended.They serve for collecting deposits, dirts, moisture and other elements that might injure the instruments or impair their precise operations. They also serve as reservoirs for sealing liquids, in the measurements of high density or corrosive fluids.

These condensate pots are also used in impulse lines for flow measurement of steam.These are available in carbon steel, stainless steel and alloy steel.these are made from seamless pipes in 3000 and 6000 lbs ratings.

Versatile End Connections

The Condensate Seal Pots are available with multiple end connection options, including butt weld, socket weld, flanged, and threaded types. This versatility enables compatibility with different piping systems, simplifying installation in new or existing setups. End connections adhere to recognized welding standards such as ASME Section IX, ensuring robust, leak-proof joints suitable for high-pressure applications.

Robust Construction and Material Choices

Clients can select from Stainless Steel (SS 304/316) or Carbon Steel for their seal pots, tailored to specific environmental and application demands. These materials provide exceptional corrosion resistance and longevity, even under rigorous temperature fluctuations from -20C to +425C. Additionally, surface treatments like polishing and sand blasting enhance durability and finish.

Wide Range of Sizes and Customization

Condensate Seal Pots are manufactured in standard sizes from 2 inch to 8 inch diameters, with thickness varying between 3 mm and 8 mm, and capacities from 1 to 10 litres. Custom dimensions and pattern details are offered to meet precise client requirements, ensuring optimal fit and performance in any application.

FAQ's of Condensate, Seal Pots:

Q: How are Condensate Seal Pots installed in steam pipelines?

A: Condensate Seal Pots can be mounted vertically or horizontally, depending on the layout and requirements of the instrumentation line. They come with a choice of end connections-such as butt weld, socket weld, flanged, or threaded-so you can select the most suitable interface for your pipeline system.Q: What is the main purpose of using a Condensate Seal Pot in instrumentation lines?

A: The primary function of a Condensate Seal Pot is to separate and collect condensate from steam within instrumentation lines, thereby protecting sensitive equipment from moisture damage and ensuring consistent measurement accuracy.Q: When should I consider custom dimensions for my Condensate Seal Pot?

A: Custom dimensions are recommended when your application requires unique specifications for capacity, diameter, or pattern size that standard models cannot accommodate. This flexibility ensures seamless integration and optimal performance in specialized setups.Q: Where can I find Condensate Seal Pots with certified welding standards?

A: You can source Condensate Seal Pots fabricated according to ASME Section IX welding standards from dealers, distributors, exporters, fabricators, manufacturers, retailers, suppliers, traders, and wholesalers across India who adhere to international quality protocols.Q: What processes are involved in testing Seal Pots for safety?

A: Each Seal Pot undergoes hydrostatic testing at 1.5 times its design pressure to verify its strength and leak-resistance. This process ensures reliability and compliance with statutory safety standards before installation.Q: How do Condensate Seal Pots benefit steam pipeline applications?

A: Seal Pots protect sensitive instrumentation from steam condensate, extending equipment life, improving operational safety, and maintaining measurement accuracy. Their durability under high pressure and temperature makes them ideal for critical systems.Q: What types of surface treatments are available for Condensate Seal Pots?

A: Surface treatments can include polished or sand-blasted finishes to enhance corrosion resistance, appearance, and longevity of the product, depending on environmental demands and client preferences.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spray Nozzle Category

AIR ATOMIZING NOZZLES FLAT JET / FULL CONE

Capacity : 0.30 8.50 LPH (Liquid flow)

Product Type : Air Atomizing Nozzle

Operating Pressure : 36 bar (recommended)

Metals Type : Other, Brass / Stainless Steel

Material : Brass / Stainless Steel

Diameter : 0.5 mm to 3.0 mm Orifice

Pneumatic Butterfly Valve

Capacity : Full Port

Product Type : Pneumatic Butterfly Valve

Operating Pressure : 48 bar

Metals Type : Other, Stainless Steel / Cast Iron

Material : Cast Iron / Stainless Steel / Aluminum Alloy

Diameter : 50 mm to 400 mm

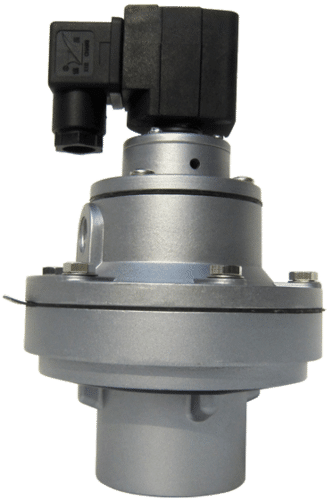

Dust Collector Solenoid Valve

Capacity : Suitable for largescale filtration systems

Product Type : 2 Way Pulse Jet Solenoid Valve

Operating Pressure : 0.5 8 bar

Metals Type : Other, Aluminum

Material : Aluminum Alloy Body, Nitrile Rubber Diaphragm

Diameter : 25mm, 40mm, 50mm (as per model)

SS Spray Ball

Capacity : Suitable for tanks up to 20,000 Liters

Product Type : Spray Ball

Operating Pressure : 0.54 bar

Metals Type : Stainless Steel

Material : Stainless Steel (SS304/SS316)

Diameter : 25 mm to 63 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry