Call: 08071931448

Industrial Spray Nozzles

Industrial Spray Nozzles Specification

- Diameter

- Varies as per model (generally 0.5 mm to 3 mm)

- Air Inlet

- BSP/NPT Threaded

- Thread size

- 1/4, 1/2, 3/4 BSP/NPT

- Capacity

- 0.3 to 15 L/min

- Pattern Dimensions

- Fine, medium, and coarse spray options

- Surface Treatment

- Nickel Plated / Polished

- Product Type

- Industrial Spray Nozzle

- Material

- Brass, Stainless Steel

- Metals Type

- Brass, Stainless Steel

- Usage

- Industrial spraying applications

- Size

- 1/4 inch, 1/2 inch, 3/4 inch

Industrial Spray Nozzles Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cheque

- Supply Ability

- 200 Per Year

- Delivery Time

- 200 Years

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- WOODEN BOX

- Main Export Market(s)

- Australia, Middle East, Western Europe, Africa, Central America, Eastern Europe, South America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2008 MSME

About Industrial Spray Nozzles

A leading client-centric organization, we have been engaged in offering a wide array of premium quality Industrial Spray Nozzles. These nozzles are carefully manufactured and designed from utilizing quality tested materials like S.S. 304, S.S. 316, Monel, Alloy 20, Heastalloy, Titanium and Polypropylene by employing advanced tools and technology in accordance with international quality standards. Furthermore, these nozzles are ideal to be used in various industrial for various applications such as Surface Treatment, Roll Cooling, Industrial washing machines, Surface spraying, Scrubbing, Foam breaking, Cooling & Washing of Gas, For High Pressure Cleaning Systems, Mould Lubricating, Spraying Injection, Air Disinfection, Humidification, Continuous Casting Cooling and lots. These Industrial Spray Nozzles can be availed from the market at industry leading prices, across the world.

Features:

Abrasion resistance

Rugged construction

Precision functionality

Durable finish

Attributes:

- Sturdy Structure

- Fine Finish

- Accurate Dimension

- Easy Installation

- Longer Service Life

- Very Low Maintenance Etc.

Highly Versatile Spray Patterns

These nozzles offer fine, medium, and coarse spray options, making them suitable for diverse industrial tasks such as targeted cleaning or broad dust suppression. The adjustable spray anglefrom a focused 15 to a wide 120ensures optimal coverage for any application, enhancing process efficiency.

Robust and Durable Construction

Manufactured from high-grade brass or stainless steel, and available in 1/4, 1/2, and 3/4 inch threaded sizes, these nozzles provide exceptional corrosion resistance and long-term durability. The nickel-plated or polished surface treatment further boosts protection in harsh environments.

Effortless Maintenance and Installation

Easy disassembly means these nozzles can be quickly cleaned or serviced, minimizing downtime. BSP/NPT threaded connections allow seamless integration into existing pipelines, catering to a wide range of industrial spraying applications and system requirements.

FAQs of Industrial Spray Nozzles:

Q: How do I select the appropriate spray nozzle for my specific industrial application?

A: Begin by determining your required spray angle, flow rate, and pattern (fine, medium, coarse). Consider your operating temperature and corrosion resistance needs, selecting either brass or stainless steel material. The connection type and nozzle size should match your systems existing BSP or NPT thread requirements.Q: What industries commonly utilize these industrial spray nozzles in India?

A: These spray nozzles are widely used in manufacturing, fabrication, cleaning services, cooling systems, coating processes, and dust suppression across sectors such as automotive, chemical, food processing, and construction industries.Q: When should maintenance or cleaning of the spray nozzle be performed?

A: Regular maintenance is recommended after extended use, especially if the spray pattern becomes irregular or flow rate decreases. Easy disassembly allows rapid, thorough cleaning to ensure consistent performance and prolong nozzle lifespan.Q: Where can these spray nozzles be installed?

A: They can be installed in any pipeline or spraying system that supports BSP or NPT threaded fittings, accommodating various diameters from 1/4 to 3/4 inch. Their corrosion-resistant construction makes them suitable for both indoor and outdoor industrial environments.Q: What is the advantage of using stainless steel nozzles over brass models?

A: Stainless steel offers superior corrosion resistance and durability, especially in harsh or chemically aggressive environments. This ensures greater longevity and reduced maintenance compared to brass, making them ideal for demanding industrial applications.Q: How is the nozzle installed and integrated into existing systems?

A: Simply match the nozzles threaded size (1/4, 1/2, or 3/4 inch) and type (BSP/NPT) to your pipework, apply appropriate sealing tape, and screw the nozzle into place. Installation requires only basic hand tools, ensuring quick setup or replacement.Q: What benefits do these spray nozzles provide to manufacturers and suppliers?

A: They deliver efficiency through precise flow control and adaptable spray patterns while minimizing downtime due to easy maintenance. Their robust, corrosion-resistant design results in cost savings on replacements and repairs, benefiting dealers, distributors, and end-users alike.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Spray Nozzle Category

AIR ATOMIZING NOZZLES FLAT JET / FULL CONE

Minimum Order Quantity : 01

Size : 1/4 inch, 3/8 inch, 1/2 inch

Pressure : 2 to 7 bar

Surface Treatment : Nickel Plated / Polished

Usage : Industrial Spray Applications

Material : Brass / Stainless Steel

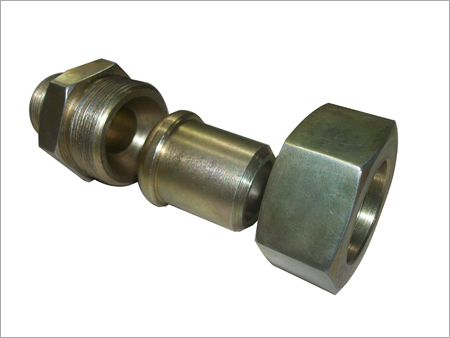

Hex Nipple With Nut

Minimum Order Quantity : 1000

Size : Standard

Pressure : 1 TO 200 kgf/cm2

Surface Treatment : Polished

Usage : Industrial

Material : Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry