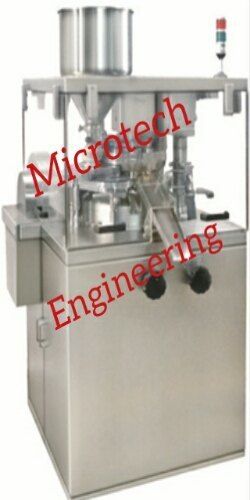

Slugging Press/ Bolus Tablet Press -Standard

Slugging Press/ Bolus Tablet Press -Standard Specification

- Frequency

- 50/60 Hz

- Features

- Heavy Duty Construction, Easy Operation, High Output, Robust Design, Easy Cleaning

- Noise Level

- Low

- Temperature

- Ambient

- Phase

- Single/Three Phase

- Usage & Applications

- Tablet slugging and bolus tablet production for pharmaceutical industries

- Type

- Slugging Press/ Bolus Tablet Press -Standard

- Material

- Stainless Steel

- Capacity

- Up to 4000 tablets/hour

- Computerized

- No

- Control Mode

- Manual

- Voltage

- 220-240 V

- Power

- 1 HP

- Weight (kg)

- Approx. 550 kg

- Dimension (L*W*H)

- 1200 mm x 850 mm x 1600 mm

- Color

- Metallic Grey/Silver

- Compliance

- cGMP Model

- Operation

- Handwheel fly-press or electric motor driven

- Shipping Weight

- Approx. 600 kg

- Die & Punch Material

- Hardened Tool Steel

- Safety Features

- Overload Protection, Interlocking Guards

- Number of Stations

- Single

- Lubrication System

- Manual/Automatic option

- Surface Finish

- Polished

- Tablet Diameter Range

- Up to 40 mm

- Max. Pressure

- 15 Ton (approx.)

Slugging Press/ Bolus Tablet Press -Standard Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Paypal, Western Union, Cash Against Delivery (CAD), Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Central America, Middle East, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Slugging Press/ Bolus Tablet Press -Standard

SLUGGING PRESS/ BOLUS TABLET PRESS -STANDARDVeterinary Bolus & Slugging Heavy Duty Single Sided Rotary Tablet PressApplication & Process :Bolus Tablet Press Machine is used for production of simple and precise tablets from powder in Pharmaceutical and relevant Industries.PTCM-SH-12 is single sided rotary slugging press with square or painted round body and suitable for small batch size production of bolus for veterinary and slugging of powder. This is a single side rotary slugging GMP/ Standard model with rigid design, precise and simple bolus tablet compression machine. It is heavy duty tablet press to take more press during compression. The PTCM-SH-12 model machine is designed to enable to maximum cleanliness in operation and accessibility, thus offering tremendous easy to operate, clean and maintenance. The PTCM-SH-12 Tablet press is offered in different two models GMP & Standard Viz. Special ToolingSalient Features : Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Simple & Convenient Operation, Changeover, Cleanliness, Operator Protection & Ease to Maintenance. Specially designed for pharmaceutical, veterinary, bolus, slugs, pellets, chemicals, plastic, ceramics, powder metals and other specialized industries. A Heavy Duty robust construction with square tubular design. Meets the requirements for capacity, precision, control, maintenance, safety and reliability. Maximum resistance to wear and tear. Overload pressure release mechanism - spring mechanism. Manual Central oil lubrication system with hand pump. All controls outside the machine.Safety Features : Overload pressure release mechanism.________________________________________Technical Specification :MODEL PTCM-SH-12 PTCM-SH-12No. of Station 12 12Type of Tooling Special SpecialOutput/Hour 10,800 and 15,800 10,800 and 15,800Max. Operating pressure 12 Tons 12 TonsMax. Tablet Diameter 28 40Max tablet thickness 11 /14 mm 11 /14 mmMax depth of fill 20 / 30 mm 20 / 30 mmMain Electric Motor 3 HP / 2.25 kW 5 HP / 3.75 kW

Heavy-Duty Construction and High Output

Designed with a robust stainless steel frame, this tablet press delivers reliable performance for demanding pharmaceutical environments. Its heavy-duty construction supports consistent operation, ensuring a high yield of up to 4,000 tablets per hour, which helps increase production efficiency and minimize downtime.

Enhanced Safety and Compliance

The Slugging Press/Bolus Tablet Press is equipped with essential safety features such as overload protection and interlocking guard mechanisms. These are complemented by compliance with current Good Manufacturing Practice (cGMP) standards, making the machine suitable for regulated industries and ensuring peace of mind during operation.

Flexible Operation and Easy Maintenance

Offering both handwheel fly-press and electric motor-driven options, this model accommodates varied production scales. Its polished surface finish and design allow for easy cleaning, maintenance, and changeover. The manual or automatic lubrication system ensures smooth, long-lasting service with minimal operational noise.

FAQ's of Slugging Press/ Bolus Tablet Press -Standard:

Q: How is the Slugging Press/Bolus Tablet Press operated?

A: The machine can be operated either manually using a handwheel fly-press or automatically via an electric motor, depending on production needs and preferences.Q: What safety features does the press include?

A: It comes with overload protection to prevent damage under excessive force and interlocking guards to ensure user safety during operation.Q: When should I use this press for tablet production?

A: This press is best used for producing large-size or high-weight tablets, such as slugs and bolus tablets, particularly in pharmaceutical industry settings.Q: Where can this tablet press be installed?

A: Its compact, upright design allows installation in pharmaceutical manufacturing plants, research facilities, or any regulated industrial production area that adheres to cGMP standards.Q: What is the typical process for producing tablets with this machine?

A: Operators load the powdered material into the die cavity, set parameters such as pressure, and the machine compresses the material into tablets. Output is smooth and consistent with regular lubrication and maintenance.Q: What are the key benefits of using this Slugging Press?

A: Key benefits include heavy-duty construction, high production capacity, compliance with industry standards, user-friendly operation, easy maintenance, and superior safety features.Q: How is cleaning and maintenance handled?

A: The polished surface and accessible components make cleaning straightforward, while manual or automatic lubrication options further ease regular maintenance, ensuring long-lasting performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

High Pressure Triplex Pumps

Voltage : 220440V (As per Model)

Control Mode : Other, Manual/Automatic

Features : Corrosionresistant body, Heavyduty construction, Low maintenance, Reliable performance

Capacity : Flow Rate: 5 to 80 LPM (Liters per Minute), Pressure: Up to 500 Bar

Power : 2 to 30 HP

Frequency : 50/60 Hz

Continuous Mixer Blender System: Simplex Mixer

Voltage : 220 V / 380 V / 415 V

Control Mode : Other, Automatic / Semiautomatic

Features : Continuous operation, Uniform blending, Adjustable speed, Energy efficient, Easy cleaning and maintenance, Robust construction

Capacity : 100 to 5000 kg/hr (customized)

Power : 5 30 kW

Frequency : 50/60 Hz

Tablet Press-ptcmb3

Voltage : 220240 V

Control Mode : Manual

Features : Robust construction, Easy operation, Low maintenance

Capacity : Up to 3600 Tablets/Hour

Power : 1 HP

Frequency : 50 Hz

Fluid Bed Equipment - Granulation & Pellet

Voltage : 220/380 V

Control Mode : Other, PLC/Manual

Features : cGMP Design, Spray Nozzle System, Easy Cleaning, Uniform Drying, Efficient Mixing, UserFriendly Interface

Capacity : 5 Kg to 500 Kg Per Batch

Power : 3 15 kW

Frequency : 50/60 Hz

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry