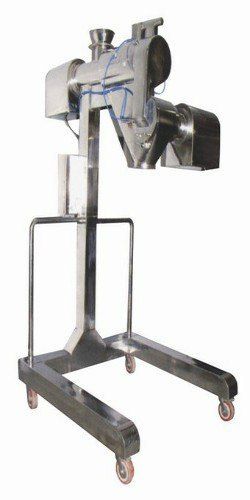

Continuous Mixer Blender System: Simplex Mixer

Continuous Mixer Blender System: Simplex Mixer Specification

- Frequency

- 50/60 Hz

- Features

- Continuous operation, Uniform blending, Adjustable speed, Energy efficient, Easy cleaning and maintenance, Robust construction

- Noise Level

- Low

- Phase

- Three Phase

- Usage & Applications

- Mixing and Blending of Powders, Granules and Solids in Food, Chemical, Pharmaceutical, and Dairy Industries

- Temperature

- Ambient to 100C

- Type

- Continuous Mixer Blender System

- Material

- Stainless Steel

- Capacity

- 100 to 5000 kg/hr (customized)

- Computerized

- No

- Control Mode

- Automatic / Semi-automatic

- Voltage

- 220 V / 380 V / 415 V

- Power

- 5 - 30 kW

- Weight (kg)

- From 500 to 2000 kg (varies as per model)

- Dimension (L*W*H)

- Custom / As per design

- Color

- Silver / Metallic Finish

- Customization Available

- Yes, as per process requirements

- Cleaning System

- CIP (Clean-in-Place) compatible

- Mixing Principle

- Ribbon/Spiral Mixing Element

- Feed System

- Manual or Automated feeding via screw conveyor or hopper

- Service Support

- Onsite installation & training provided

- Surface Finish

- Mirror/Matte polishing as required

- Operating Environment

- Indoor, Dust-free environment recommended

- Discharge Type

- Bottom Outlet (Butterfly or Slide Gate Valve)

- Compliance

- CE certified / GMP compliant

- Installation

- Skid-mounted or Floor-mount

- Design

- Simplex Mixer with horizontal agitator

- Safety Features

- Overload protection, Emergency stop switch

- Recommended Particle Size

- Up to 10 mm

- Drive System

- Heavy Duty Gearbox with Electric Motor

Continuous Mixer Blender System: Simplex Mixer Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Western Union, Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Continuous Mixer Blender System: Simplex Mixer

Continuous Mixer Blender System: Simplex Mixer

Continuous Effective Mixing Process Technic Application & Process :

The Single Shaft Continuous Paddle Mixer Blender is designed for uniformly wet & dry mixing and blending technology provides the ideal environment for effectively optimum mixing a wide distribution of particle size and bulk densities without segregation of powder, granular, short fibered, moist solids and liquids together with pasty substances up to and including highly viscous masses in the pharmaceutical, chemical, herbal, cosmetic, food, pesticides, detergents, and plastics industries. The Mixer produces high quality intermediate and end product with homogeneity. Extremely fragile products are handled very gently. Micro ingredients are accurately mixed. Dry Solid Blending Solid and liquid blends Coating Granulation Flavoring Premixing for extrusion

Single shaft continuous mixer make material rotate along with main shaft. Mixer agitator break material and mix material in the mean time. It is suitable for mixer material with different density, size, etc. Continuous mixer depend on continuous and proportioned feeding, so should be combined with feeding system.During mixing process fluidization assures homogeneous mixes independent of large range of particle size, shape or density. The paddles are positioned to move the material in lateral directions as well as radically. The mixer consists of a rigid fabricated structure motor, gear box, mixing U-shaped horizontal drum and peddle type stirrer.

Salient Features :

High mixing technology provides the ideal environment for effectively mixing a wide distribution of particle size and bulk densities without segregation. Fluidization assures homogeneous mixes independent of large range of particle size, shape or density Extremely gentle with fragile ingredients Fast, even liquid addition and coating by spraying system. Ideal for agglomerating and No over mixing Easy, fast and complete discharge. Low space requirements. Available in Capacity 250 to 75,000 Liter per hour. Design is cGMP - Current Good Manufacturing Practices compliance All Product contact parts AISI 316/ 316L & non contact parts AISI 304. Product container trough types : "U" shape OR Round Direct drive gear box with motor. Shaft seal both side with stuffing box with food grade seal.

Safety Features :

Total drive transmission system enclosed Limit switch installed in the top lid ensure lid is closed Overload relay Protection and Emergency stop button

Model Nominal Capacity Tons/ hour Nominal Motor HP Shaft Length in cm Container Width In cm Height In cmPCM- 180 5 PCM-250 7 PCM-300 9 Please contact us for more details. PCM-365 10 PCM-425 12

State-of-the-Art Mixing Performance

Utilizing a ribbon or spiral mixing element with a horizontal agitator, this simplex mixer guarantees consistent and efficient blending for diverse batch sizes and material types. The robust gearbox and electric motor ensure continuous operation and reliability in demanding industrial environments.

User-Friendly Operation and Maintenance

The system can be operated manually or automatically, with feeding through screw conveyors or hoppers. Its design supports easy cleaning, including CIP compatibility, and features overload protection, an emergency stop switch, and low noise for a safe and comfortable workplace.

Customizable and Compliant Solutions

Designed for flexibility, the mixer is available in various capacities, voltage options, and polishing finishes. It can be configured for different process requirements and is compliant with CE and GMP standards, making it suitable for sensitive applications in regulated industries.

FAQ's of Continuous Mixer Blender System: Simplex Mixer:

Q: How does the Simplex Mixer ensure uniform blending of materials?

A: The mixer employs a horizontal agitator with ribbon or spiral mixing elements, providing thorough and uniform blending of powders, granules, and solids through continuous axial and radial motion.Q: What particle size and materials can the mixer handle?

A: This system efficiently processes particles up to 10 mm and is suitable for powders, granules, and solids commonly found in the food, pharmaceutical, chemical, and dairy industries.Q: When is it recommended to use the CIP cleaning feature?

A: The CIP (Clean-in-Place) system should be utilized after each production batch or when changing products to ensure hygienic operation, especially in pharmaceutical or food processing applications.Q: Where can the Continuous Mixer Blender System be installed?

A: The system supports both skid-mounted and floor-mounted installations, best suited for indoor, dust-free environments to maintain optimal performance and safety.Q: What benefits does the heavy-duty gearbox and electric motor provide?

A: These components guarantee reliable, energy-efficient operation and support continuous mixing even with heavy or dense materials, reducing downtime and maintenance needs.Q: How does the mixer support safe operation?

A: Safety features include overload protection and an emergency stop switch, ensuring rapid response in case of unusual load or operational anomalies for operator safety.Q: What customization options are available for this system?

A: The mixer can be tailored in terms of capacity, dimensions, control mode (automatic or semi-automatic), surface finish, and feeding methods, according to the specific process requirements of each client.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

Sigma Mixer / Kneader Mixer- Z Blade

Control Mode : Other, Automatic / Semiautomatic

Color : Grey or as per requirement

Computerized : No

Material : Stainless Steel, Mild Steel

Type : Other, Sigma Mixer / Kneader Mixer Z Blade

Voltage : 220V / 380V / 415V

Turbo Sifter

Control Mode : SemiAutomatic

Color : Metallic Silver

Computerized : No

Material : Stainless Steel (SS304/SS316)

Type : Other, Industrial Turbo Sifter

Voltage : 220 V / 380 V

Ointment Plant

Control Mode : Automatic

Color : Silver

Computerized : Yes

Material : Stainless Steel (SS 316/SS 304)

Type : Other, Ointment Plant

Voltage : 220 V / 380 V

High Shear Mixer Granulator-HSMG Rapid Mixer Granulator - RMG

Control Mode : Other, Automatic / SemiAutomatic

Color : Stainless Steel Finish (Silver/Grey)

Computerized : Other, Yes (optional PLC/HMI control)

Material : Stainless Steel (SS316 / SS304 contact parts)

Type : Other, High Shear Mixer Granulator (HSMG) / Rapid Mixer Granulator (RMG)

Voltage : 380 V / 415 V AC

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry