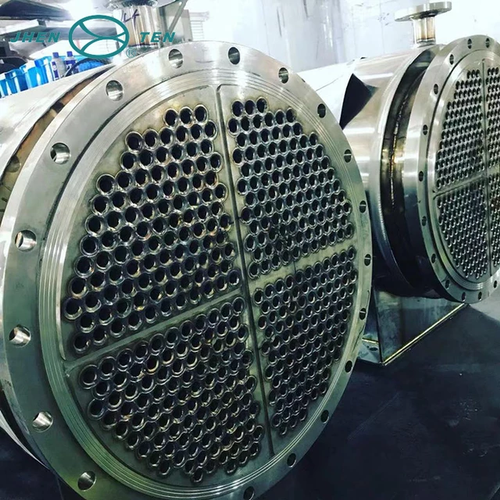

Shell And Tube Heat Exchangers

Shell And Tube Heat Exchangers Specification

- Product Type

- Shell And Tube Heat Exchangers

- General Use

- Industrial Heat Transfer Applications

- Material

- Stainless Steel/Carbon Steel

- Type

- Shell & Tube

- Capacity

- Up to 10000 LPH (customizable)

- Weight (kg)

- Varies as per design (approx. 500-2000 kg)

- Computerized

- No

- Automatic

- No

- PLC Control

- Optional

- Heating System

- Hot Fluid/Steam Circulation

- Voltage

- Not applicable (unless supplied with pump)

- Motor

- Not included (optional for skid units)

- Dimension (L*W*H)

- As per requirement/design

- Packaging Material

- Standard Export Packing/Wooden Box

- Feature

- High Thermal Efficiency, Robust Construction, Easy Maintenance

- Color

- Metallic Silver/Grey

- Cleaning Method

- CIP or Manual Cleaning

- Maintenance Access

- Manhole and End Covers

- Service Medium

- Oil, Water, Steam, Chemicals, Air, etc.

- Tube Bundle

- Removable or Fixed as per requirement

- Mounting Type

- Horizontal/Vertical

- Leak Test

- Pneumatic/Hydrostatic

- Tube Material

- SS304, SS316, Copper, Titanium

- Corrosion Resistance

- Yes, depends on selected materials

- Surface Finish

- Polished or Matt Finish

- Tube Diameter

- 12.7 mm / 15.88 mm / custom sizes

- Test Pressure

- 1.5 times design pressure

- Connections

- Flanged/Screwed as per request

- No. of Passes

- Single or Multiple Passes

- Design Pressure

- Up to 20 bar (customizable)

- Shell Material

- Mild Steel/SS304/SS316

- Design Temperature

- Up to 400°C

- Standards

- ASME/TEMA/IS codes

Shell And Tube Heat Exchangers Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Cheque, Telegraphic Transfer (T/T), Western Union, Paypal, Letter of Credit (L/C), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Asia, Australia, North America, Eastern Europe, Western Europe, Middle East, Central America, South America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Shell And Tube Heat Exchangers

Shell and Tube Heat Exchangers, Pressure Vessels, Columns, Filter Dryers, Reactors and Complete Pre-Assembled Units Features: 1. Intensified Heat Transfer The spiral copper coil pipe is fixed by the cantilever construction. As the hot mediators(saturation steam or high-temperature water)pass the pipe, The pipeas high-speed round trip motion causes perturbation motion of the water around the heat exchanger tubes forcedly, and this increases the heat transfer coefficient aKa, reduces the fluidas thermal resistance on the tubes outer wall al/a0a, and enhances the total heat transfer coefficient.2. Less solid fouling Bcause of the coil pipeas float with high speed, the fouling will be deposited and adheres to the pipeas outer wall difficultly during the operation process. At the same time, Even though there is a little fouling on the pipeas outer wall, the fouling will break off automatically because the coil pipe will flex along with temperature change,therefore the traditional fouling-release technique is needless and the heat exchanger can keep the best work condition for long term.3. The accurate temperature controlThe heat exchanger is collocated with the high-accuracy aintellectualized temperature adjustera, it can inspect the water temperature continuously and automatically and will instruct the controlling valves to regulate the flowing quantity of the hot mediator in the coil pipe, the outlet water temperature will be kept in the scope of A2AC of the set point in the case that the charge is waving. 4. Less floor spaceThe exchanger has compact structure,so the floor space required is only 10 percent of the tubular heat exchanger that has the same function. The fabrication cost is reduced and space is utilized efficiently, it is also convenient for hoisting assembly and transportation.Flexible Tube Bundle Design

Select either removable or fixed tube bundles based on your maintenance requirements. Removable designs simplify cleaning and replacement, while fixed bundles offer higher structural integrity for specific applications. The number of tube passes can be customized to optimize thermal performance according to process needs.

Durable Construction and Material Options

Shell and tube heat exchangers are fabricated from high-grade stainless steel, carbon steel, copper, titanium, and mild steel. Material choice ensures compatibility with various service mediums and resistance to corrosion. The shell and tube assembly can be finished in polished or matt, depending on operational aesthetics and hygiene requirements.

Rigorous Compliance and Testing

Each unit complies with stringent ASME, TEMA, and IS standards. Quality assurance involves hydrostatic or pneumatic leak testing at 1.5 times the design pressure. The equipment is delivered in secure packaging and can be tailored to meet specific dimensional and connection requirements.

FAQ's of Shell And Tube Heat Exchangers:

Q: How do I decide between a removable and a fixed tube bundle for my heat exchanger?

A: Removable tube bundles are ideal when regular cleaning or tube replacement is anticipated, offering easier maintenance access. Fixed tube bundles are preferred in processes where structural strength and minimal intervention are required. Selection depends on your process maintenance schedule and operating environment.Q: What are the benefits of multiple tube passes in a shell and tube heat exchanger?

A: Multiple tube passes increase the heat transfer efficiency by allowing the fluid to travel through the tubes several times, thereby improving thermal performance. This configuration is especially beneficial for processes requiring substantial temperature changes within limited space.Q: Where can these heat exchangers be installed and how is mounting type determined?

A: Installation is versatile; heat exchangers can be horizontally or vertically mounted, depending on available space and process flow considerations. The choice of mounting impacts maintenance access, ease of cleaning, and integration with existing equipment.Q: What cleaning methods are available and when should I use CIP versus manual cleaning?

A: Cleaning In Place (CIP) is suitable for applications requiring frequent cleaning without disassembly, reducing downtime and labor. Manual cleaning is more suited for less frequent maintenance or when dealing with heavy fouling that requires physical intervention. Selection depends on process hygiene standards and maintenance logistics.Q: How does material selection affect corrosion resistance and overall durability?

A: The choice of tube and shell materials directly influences corrosion resistance and longevity. Stainless steels (SS304, SS316), copper, and titanium offer excellent resistance against most service media, while mild steel is cost-effective but less suitable for corrosive environments. Material customization ensures optimal performance for specific industrial fluids.Q: What industries commonly use shell and tube heat exchangers, and why?

A: Industries such as chemical processing, oil & gas, power generation, pharmaceuticals, and food production rely on shell and tube heat exchangers for robust, reliable heat transfer. Their adaptability in handling various fluids, high-pressure tolerance, and efficient thermal performance make them indispensable for industrial heat management.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Machinery Category

Hand Sanitizer Making Plant

Price 350789.00 INR / Number

Minimum Order Quantity : 1 Number

Drive Type : Other, Electric Motor Driven

PLC Control : Other, Available

Product Type : Hand Sanitizer Making Plant

Capacity : 100 L to 5000 L

BALL MILL

Price 127546 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

PLC Control : Yes

Product Type : INDUSTRIAL

Capacity : 1 TO 10 m3/hr

Drum Mixers

Drive Type : Other, Electric Motor

PLC Control : No

Product Type : Drum Mixer

Capacity : Up to 200 Liters (standard for 200L drums)

Liquid Phenol Mixer Plant

Drive Type : Other, Motor driven (Gearbox coupled)

PLC Control : Other, Available

Product Type : Liquid Phenol Mixer Plant

Capacity : 500 L to 10,000 L per batch (customizable)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry