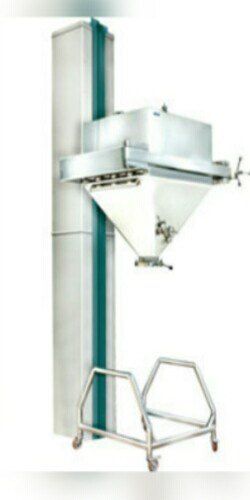

Pharmaceutical Transfer Pump

Pharmaceutical Transfer Pump Specification

- Features

- Sanitary design, CIP/SIP compatible, leak-proof construction, low maintenance

- Temperature

- Up to 80C

- Phase

- Single/Three Phase

- Noise Level

- Low (<70 dB)

- Usage & Applications

- Suitable for transferring pharmaceutical solutions, clean liquids, and sterile fluids in pharmaceutical industries

- Frequency

- 50 Hz

- Type

- Pharmaceutical Transfer Pump

- Material

- Stainless Steel (SS 316/304)

- Capacity

- Up to 5000 LPH

- Computerized

- No

- Control Mode

- Manual

- Voltage

- 220-240 V

- Power

- 0.5 to 3 HP

- Weight (kg)

- Approx. 40 kg

- Dimension (L*W*H)

- 650 x 360 x 520 mm

- Color

- Silver & Blue

- Seal Type

- Mechanical Seal

- Pump Orientation

- Horizontal

- Head Range

- Up to 30 meters

- Impeller Type

- Open/Closed

- Surface Finish

- Electropolished for hygienic application

- Installation

- Portable on trolley

- Pump Type

- Centrifugal

- Connection Type

- Tri-Clamp or DIN standard

- Motor Protection

- IP55

- Flow Range

- Variable flow rate adjustment available

- Inlet/Outlet Diameter

- 25 mm to 50 mm

Pharmaceutical Transfer Pump Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Western Union, Paypal, Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Pharmaceutical Transfer Pump

Pharmaceutical Transfer Pump

- Head : 48 meter

- Capacity : 33 m3/h

- Delivery size : 12mm to 65 mm

- Temperature : -10 to 95 degree Celsius

- Test pressure : 10 kg/cm2

Standard futures :

- Centrifugal single stage

- Flange as per din standard

- Back pull out design

- Open / close impeller

- Shaft sealing by single / doable mechanical seal

- Sealed grease lubricated , deep grove ball bearing

- He pump handle liquid having viscosities up to 1500 centrioles

- Also with flame proof motor

Optional futures :

- Shaft sealing by gland packing

- Bearing lubricating by oil

- ANSI drilling on DIN flanges

- Trolley mounting arrangement

- Various type of connection

- Casing : st. Steel ( cf8 / cf8m )

- Shaft : st. Steel ( ss 410 / ss 316 / ss 304 )

- Impeller : st. Steel ( ss 410 / ss 316 / ss 304 )

- Back Plate: st. Steel ( ss 410 / ss 316 / ss 304 )

- Mechanical Seal : TC/TC , SIC/SIC TEFLON/ GFT

- MOTOR COVER : SS 304 , SS 316

- GASKET : Viton / Nitrile/ Silicon / PTFE

Reliability :

The pump are hydraulically designed for maximum efficiency. Every pump passes through stringent process & quality control plans and is designed to give longer life with consistent performance and trouble free service.

Application :

- Dairy industries

- Food processing plant

- Pharmaceutical industries

- Sugar & confectionery

- Bottling plants

- Distillery

- Beverages

- Water treatment plants

- Colors dies & pigments / paints

- Descaling application

- Sagar industries

- Hot & cold water pumping

- Sparkling filter press

- Sugar syrup

- Chemical processing

Due to content research & development data is subject to change

Superior Sanitary Design for Pharmaceutical Applications

Engineered for uncompromising hygiene, this transfer pump boasts an electropolished surface and leak-proof mechanical sealing. CIP/SIP compatibility and an easy-to-clean structure make it ideal for environments where sanitation and sterility are critical, such as pharmaceutical production lines dealing with sterile fluids and clean liquids.

Flexible & Portable Operation

The pump offers both open and closed impeller types and supports variable flow rates up to 5000 LPH, accommodating a wide range of pharmaceutical processes. Its portable trolley-mounted construction allows for convenient repositioning, ensuring seamless integration into various operational layouts within the industry.

FAQ's of Pharmaceutical Transfer Pump:

Q: How does the centrifugal mechanism benefit the pharmaceutical transfer pump?

A: The centrifugal design enables steady, non-pulsating fluid flow, minimizing shear and ensuring gentle handling of sensitive pharmaceutical solutions, which is crucial for retaining product quality during transfer.Q: What applications is this pharmaceutical transfer pump suitable for?

A: This pump is ideal for transferring clean liquids, sterile solutions, and pharmaceutical products in production facilities, ensuring contaminant-free movement of fluids thanks to its hygienic, stainless steel construction.Q: When should I use variable flow rate adjustment?

A: The variable flow rate feature should be used when different batch sizes or process requirements demand precise control over fluid transfer, optimizing process efficiency and preventing product wastage.Q: Where can the pump be installed for optimal performance?

A: Its portable trolley-based design enables flexible installation wherever needed within your facility, including cleanrooms, process areas, and close to production lines, ensuring ease of access during operations.Q: What is the process for cleaning and maintaining the pump?

A: Routine cleaning is straightforward due to its electropolished surfaces and sanitary tri-clamp or DIN connections. The pump is fully CIP/SIP compatible, allowing for thorough automated cleaning in place without disassembly.Q: How does the IP55 motor protection enhance safety?

A: The IP55 rating safeguards the pump's motor against dust and water ingress, which is vital in pharmaceutical environments where wash-down procedures and incidental contact with liquids are common.Q: What benefits does the leak-proof mechanical seal provide?

A: The mechanical seal ensures leak-proof operation, preventing contamination of products and maintaining a safe, clean working environment-a critical factor in pharmaceutical manufacturing.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pharmaceutical Machinery Category

Bin Blender

Material : Stainless Steel (SS 304/316L)

Control Mode : Other, Manual / PLC Based

Color : Metallic/Silver

Voltage : 220380V

Skid Cip / Wip System

Material : Stainless Steel (SS304/SS316)

Control Mode : Other, Automatic / SemiAutomatic

Color : Metallic Silver / Polished Steel

Voltage : 220V / 380V / 415V (as required)

Tablet De-Duster

Price 120573 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Control Mode : Automatic

Color : Sliver

Voltage : 220 Volt (v)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry