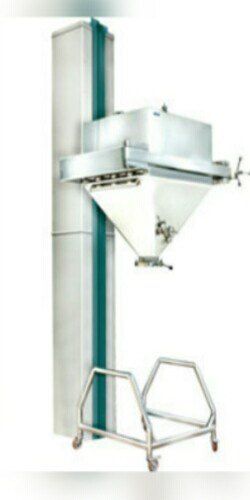

Bin Blender

Bin Blender Specification

- Noise Level

- Low

- Phase

- Single/Three Phase

- Features

- Uniform mixing, dust-free operation, easy loading & unloading, safety interlocks

- Frequency

- 50/60 Hz

- Temperature

- Ambient

- Usage & Applications

- Mixing, blending dry powders and granules for pharmaceuticals, chemicals, and food processing industries

- Type

- Bin Blender

- Material

- Stainless Steel (SS 304/316L)

- Capacity

- 50 to 1200 Liters

- Computerized

- No

- Control Mode

- Manual / PLC Based

- Voltage

- 220-380V

- Power

- 2-7 kW

- Weight (kg)

- Approx. 350-1500 kg

- Dimension (L*W*H)

- As per model (Customizable)

- Color

- Metallic/Silver

- Drive System

- Electric motor with gear box

- Cleaning

- Easy to clean with minimum residue

- Mobility

- Mounted on castor wheels for easy movement

- Inlet/Outlet Size

- Customizable as per requirements

- Batch Time

- Mixing cycle 6-12 minutes

- Surface Finish

- Mirror/Matte finish

- Operation

- Continuous or batch mode

- Installation

- Floor mounted

- Maintenance

- Low maintenance requirements

- Suitable Bin Sizes

- Interchangeable bins for flexibility

- Safety Features

- Emergency stop, locking system, safety guard

- Applicability

- Ideal for pharmaceutical, chemical, and food blends

- Automation Grade

- Semi/Automatic options available

- Blending Angle

- 45-180 degrees adjustable

Bin Blender Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cheque, Letter of Credit (L/C), Western Union, Paypal, Telegraphic Transfer (T/T), Cash in Advance (CID)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Western Europe, Asia, Australia, North America, South America, Eastern Europe, Middle East, Africa, Central America

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Bin Blender

Bin Blender

Bin Blender IBC Bin /Cage /Conta Blender Dust Free Effective Process Technik Of Uniform Mixing Lubricating & Blending Of Dry Power & Granules.

Application & process- Design is GMP - Current Good Manufacturing Practices compliance All Product contact parts AISI 316 & non contact parts AISI 304. IBC Bin Blender for Ideal dry mixer for lubrication of granules and homogenization mixing and conveying of the material to further process. Available Capacity: 25 kg to 500 kg batch size. Interchangeable different capacity IBC Bin can be used on same machine use for mixing. This is a closed and contained system where by a single step transfer material from Container of the Conta blender is transferred to the tablet press hopper. In granulation room the dry granules enter to the container for blending through a dust free connection and the same container is loaded over to the blender for blending Totally dust free. Also another advantage is adaptability of this system to handle more than one size of bunkers or containers so processing of different sizes of production batches in single equipment. Enclosed rigid drive with reduction gear box and motor in the machine structure. Hydraulic power pack system for lifting of product bin for mixing. A suitable reeling around the cage with one entry point for the bin on detachable trolley The charging hole with cover is provided on top with quick opening and closing arrangement with dust proof joints for particle free transfer. IBC Bin having discharge with butterfly valve and trolley for easy mobility. Electric controls panel with cycle time

Optional Features : Interchangeable Product Container AC Frequency variable drive for product container. PLC Controls with HMI touch screen, Flame proof motor and Push Button station.

Safety Features : Limit switch on entry door to prevent the accidental operation of the cage, Overload relay protection & Emergency stop button..

Efficient Mixing Performance

Experience swift and consistent batch mixing with cycle times between 6 to 12 minutes. The adjustable blending angle from 45 to 180 allows for process optimization depending on material characteristics. Uniform mixing and dust-free operation help maintain product quality and workplace hygiene.

Safety and User Convenience

Safety is prioritized with an emergency stop, locking system, and comprehensive safety guards. Bin or batch loading and unloading are effortless, supported by the ergonomic design and low-noise operation. Cleaning is hassle-free, reducing downtime and residue build-up.

Flexible Installation and Operation

The blender is suitable for continuous or batch mode, catering to varied production demands. With a customizable design including inlet/outlet and bin sizes, it supports floor-mounted installation and easy movement through sturdy castor wheels, ensuring adaptability to different workspace requirements.

FAQ's of Bin Blender:

Q: How does the adjustable blending angle benefit the mixing process in the Bin Blender?

A: The adjustable blending angle from 45 to 180 degrees enables optimal material agitation, ensuring uniform mixing of powders and granules for diverse applications. This flexibility allows operators to set the ideal angle based on the product and batch size, improving blending efficiency.Q: What safety features are included in the Bin Blender, and how do they enhance operator protection?

A: The Bin Blender is equipped with emergency stop buttons, locking systems, and safety guards. These features help prevent accidents, unauthorized access, and contact with moving parts during operation or cleaning, thereby promoting a secure workplace environment.Q: When should the Bin Blender be cleaned, and what makes its cleaning process easy?

A: It is recommended to clean the blender after each batch or product changeover to maintain hygiene and avoid cross-contamination. The design ensures easy access and minimal residue retention, allowing for quick and thorough cleaning with minimal disruption to production.Q: Where can the Bin Blender be installed, and how does its mobility feature assist in placement?

A: The blender is floor-mounted for stable operation but is fitted with castor wheels, making it easy to move and reposition within the processing area. This flexibility is particularly useful in dynamic manufacturing environments or when adjusting space layouts.Q: What are the benefits of using interchangeable bins, and how does this enhance productivity?

A: Interchangeable bins accommodate a range of batch sizes-from 50 to 1200 liters-providing flexibility for different production volumes. This feature enables seamless transitions between products and efficient batch management, enhancing overall process productivity.Q: How does the Bin Blender ensure uniform mixing and dust-free operation for pharmaceutical, chemical, and food applications?

A: The combination of optimized bin design, adjustable blending angles, and robust drive system ensures even distribution of materials. Its sealed construction minimizes the risk of dust emission, maintaining cleanliness and safeguarding product integrity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

Automatic Hand Sanitizer Machine

Material : Stainless Steel Body

Voltage : 220V AC

Color : Silver

Computerized : No

Industrial mixer and blenders

Material : Stainless Steel

Voltage : 220V/380V

Color : Metallic Silver

Computerized : No

Dispohomo Reactor: High Shear Dispersion

Material : Stainless Steel (Grade SS304/SS316)

Voltage : 415 V

Color : Metallic Silver

Computerized : No

Pneumatic Perfume Filtration Unit

Material : Stainless Steel (SS 304/316)

Voltage : 220240 V

Color : Silver

Computerized : No

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry