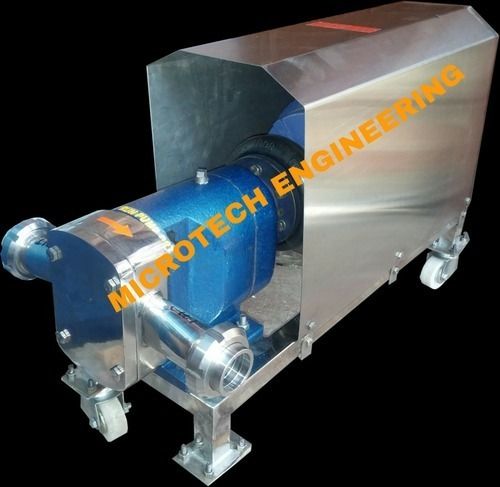

Thick Liquid Transfer Pump

Thick Liquid Transfer Pump Specification

- Theory

- Centrifugal Pump

- Features

- Corrosion-resistant, Easy to clean, High Viscosity Handling

- Voltage

- 220V / 380V

- Flow Rate

- 10-50 m/h

- Noise Level

- <75 dB

- Caliber

- 50 mm

- Control System

- Manual/Automatic

- Working Temperature

- -10C to 80C

- Inlet/Outlet

- 2 inch / 1.5 inch

- Mounting Type

- Base Mounted

- Max Suction

- 7 m

- Head Size

- 10-40 m

- Speed

- 1450 rpm

- Discharge Pressure

- Up to 4 Bar

- Frequency

- 50 Hz / 60 Hz

- Material

- Stainless Steel

- Structure

- Single-stage Pump

- Power

- 1.5 kW 5.5 kW

- Standard

- ISO 9001 Certified

- Fuel Type

- Electric

- Pressure

- Up to 4 Bar

- Usage

- Industrial, Chemical, Food Processing

- Application

- Thick liquid/slurry transfer

- Suction Type

- Positive Displacement

- Seals Type

- Mechanical Seal

- Priming

- Self Priming

- Pump Type

- Thick Liquid Transfer Pump

- Capacity

- 10-50 m/h

- Shaft Material

- SS 304 / SS 316

- Color

- Silver/Grey

- Impeller Type

- Open/Closed Impeller

- Weight

- Approx. 65 kg

- Maximum Viscosity Handled

- Up to 50,000 cP

- Installation

- Horizontal

- Protection Class

- IP55

- Cooling Method

- Air Cooled

Thick Liquid Transfer Pump Trade Information

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 200 Per Year

- Delivery Time

- 200 Years

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- WOODEN CHARGE

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Middle East, Western Europe, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2008 MSME

About Thick Liquid Transfer Pump

Thick Liquid Transfer Pump

MICROTECH ENGINEERING

Lobe pumps are used in a variety of industries including, pulp and paper, chemical, food, beverage, Pharmaceutical, and biotechnology. They are popular in these Diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics. These pumps offer a variety of lobe options including single, biwing, tri-lobe (shown), and multi-lobe.Rotary lobe pumps are Non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self- priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous.

Exceptional Viscosity Handling

This pump excels at transferring thick liquids with viscosities reaching up to 50,000 cP, making it ideal for slurries, food mixtures, and various industrial chemicals. Its robust design and open/closed impeller choices help avoid clogging, ensuring seamless operation even under challenging conditions.

Built for Durability and Safety

Constructed from stainless steel (SS 304 / SS 316), the pump resists corrosion and chemical damage. The air-cooled design, mechanical seal, and IP55-rated protection ensure long-term, reliable service, even in demanding environments. It complies with ISO 9001 standards, reflecting a commitment to superior quality.

Flexible Installation & Control Options

The pump supports horizontal, base-mounted installation and can be managed via manual or automatic control systems. With dual voltage compatibility (220V / 380V) and frequency options (50 Hz / 60 Hz), it seamlessly integrates into new or existing setups in a range of industrial facilities.

FAQs of Thick Liquid Transfer Pump:

Q: How can the Thick Liquid Transfer Pump be installed in my facility?

A: This pump is designed for horizontal, base-mounted installation. It integrates easily with both new and existing pipelines, and can be connected via its 2-inch inlet and 1.5-inch outlet. Installation guidelines are covered in the supplied manual, and local suppliers or distributors in India can provide onsite setup assistance if needed.Q: What types of fluids can this pump handle effectively?

A: The pump is engineered for thick liquids and slurries, handling viscosities up to 50,000 cP. It is suitable for transferring chemicals, food products, or any industrial fluids that require robust agitation and flow, thanks to the open or closed impeller configurations and positive displacement suction design.Q: When should I use the open impeller versus the closed impeller type?

A: Open impellers are optimal for fluids containing solid particles or fibrous materials, reducing the risk of clogging. Closed impellers, on the other hand, are preferred for handling clean, viscous liquids that require higher efficiency and pressure stability.Q: Where can I purchase or source this pump in India?

A: The Thick Liquid Transfer Pump is widely available across India through authorized dealers, distributors, exporters, manufacturers, suppliers, traders, wholesalers, and retailers. Many provide additional services such as installation, customization, and ongoing maintenance support.Q: What maintenance process is recommended to ensure long pump life?

A: Regular cleaning and inspection are essential, as the pumps stainless steel construction makes it easy to clean. It is advisable to periodically check the mechanical seals, impeller, and bearings. The air-cooled design aids heat dissipation, and its noise level remains below 75 dB during operation, facilitating comfortable maintenance routines.Q: How does using this pump benefit my industrial processes?

A: Utilizing this pump streamlines the transfer of dense, high-viscosity materials, increases throughput, and reduces the risk of equipment blockages. Its corrosion-resistant build, high suction capabilities, and ISO 9001 quality assurance support reliability and operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lobe Pump Category

Lobe Pump

Price 75245 INR

Minimum Order Quantity : 1 Box

Pressure : Other, up to 1.2 MPa

Theory : Other, Rotary Lobe Pump

Flow Rate : up to 120 m/h

Seals Type : Mechanical Seal / Lip Seal / Gland Packing

Steam Jacketed Rotary Lobe Pump

Minimum Order Quantity : 01

Pressure : Other, Up to 12 Bar

Theory : Other, Rotary Lobe Pump, Positive Displacement

Flow Rate : Up to 70 m/h

Seals Type : Mechanical Seal / Lip Seal / Gland Packing

Cheese Transfer Pump

Pressure : Other, Max 4 Bar

Theory : Other, Rotary Lobe Pump

Flow Rate : Up to 25000 LPH

Seals Type : Mechanical Seal

Coffee Transfer Pump

Pressure : Other, Up to 3 bar

Theory : Centrifugal Pump

Flow Rate : 40 to 300 LPM

Seals Type : Mechanical Seal

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry