Semi Automatic Liquid Filling Machines

Semi Automatic Liquid Filling Machines Specification

- Temperature

- Ambient

- Phase

- Single Phase

- Frequency

- 50 Hz

- Noise Level

- <65 dB

- Usage & Applications

- Filling of liquids such as oil, syrup, juice, shampoo, sanitizer, etc.

- Features

- Easy to operate, High accuracy, Drip free nozzle, Compact design, Low maintenance

- Type

- Semi Automatic Liquid Filling Machine

- Material

- Stainless Steel

- Capacity

- 100 ml to 1000 ml per stroke (customizable)

- Computerized

- No

- Control Mode

- Pneumatic / Manual

- Voltage

- 220V AC

- Power

- 0.5 HP

- Weight (kg)

- 80 kg

- Dimension (L*W*H)

- 900 x 500 x 1000 mm

- Color

- Silver

- Air Pressure Requirement

- 0.4 - 0.6 MPa

- Product Contact Parts

- SS 304/316

- Filling Speed

- 10-30 bottles per minute

- Suitability

- Free-flowing and semi-viscous liquids

- Movability

- Mounted on caster wheels

- Maintenance

- Easy to clean and service

- Hopper Capacity

- 25 Liters

- Operator Requirement

- One operator

- Filling Accuracy

- ±1%

- Nozzle Type

- Drip-free, single/double nozzle

Semi Automatic Liquid Filling Machines Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Paypal, Western Union, Cash Against Delivery (CAD), Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Western Europe, South America, Eastern Europe, Middle East, Central America, Asia, North America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Semi Automatic Liquid Filling Machines

Versatile Applications for Diverse Liquids

The Semi Automatic Liquid Filling Machine shines as a reliable choice for a wide usage spectrum, from oils and syrups to juice, shampoo, sanitizers, and beyond. Developed for semi-industrial and commercial settings, its ideal for businesses requiring precise and efficient filling of free-flowing and semi-viscous media. Designed for single-operator usage, the machine supports both drip-free single and double nozzle filling, ensuring flexibility, product consistency, and optimal workflow in bottling lines of various industries.

Broad Market Reach & Secure Supply Chain

Our machine serves an extensive domestic market and reaches main export destinations with proven supply ability. We offer efficient order processing and secure shipping, ensuring that clients receive their machinery swiftly and safely, wherever they are. With a commitment to first-rate customer experiences, we consistently fulfill large and small orders, supporting businesses as trusted partners in distribution, fabrication, retail, and wholesale sectors across India and abroad.

|

Semi Automatic Liquid Filling Machines |

|

MICROTECH ENGINEERING |

|

As being leading manufacturer and suppliers of liquid filling machine, we offer optimum quality range of the automatic liquid filling machines. It is conveniently used for variety of liquids. It displays good automation for the effective operation. It works with + or 1 % accuracy. It also offers vibration free construction. Machine is built with high grade steel. operation of the machine has made the machine so user-friendly. A/C frequency drive prevent machine from short circuits. Belt conveyor is used to move the bottle to nozzles. There is no wastage of material due to precise operational system. Hassle free automation Machine build as per GMP standard Least change over time Self lubricating system Wear and tear resistant |

FAQs of Semi Automatic Liquid Filling Machines:

Q: How accurate is the filling process with this semi automatic liquid filling machine?

A: The machine delivers outstanding filling accuracy, maintaining a deviation of only 1%, ensuring consistent and precise results with every operation.Q: What types of liquids can be filled with this machine?

A: It is masterfully engineered for both free-flowing and semi-viscous liquids such as oil, syrup, juice, shampoo, sanitizer, and similar products.Q: Where can this filling machine be installed for optimal use?

A: Thanks to its compact design and caster wheels, it can be conveniently installed in diverse settingsfactories, production lines, small workshops, or laboratorieswhere bottling of liquids is required.Q: What is the process for cleaning and maintaining the machine?

A: All product contact parts are made from easy-to-clean stainless steel (SS 304/316), and the design facilitates swift disassembly, making maintenance both simple and efficient.Q: What are the main benefits of using a drip-free nozzle system?

A: The exclusive drip-free nozzle system minimizes product wastage and ensures a cleaner bottling environment, supporting top-tier production hygiene and cost savings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

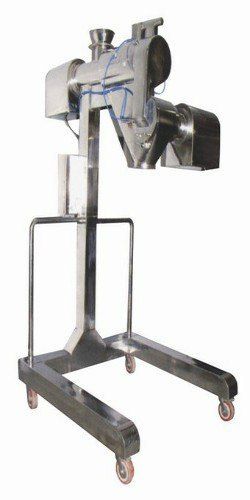

Turbo Sifter

Color : Metallic Silver

Material : Stainless Steel (SS304/SS316)

Power : 1 3 HP

Features : High sieving efficiency, GMP compliant design, Easy cleaning, Dustfree operation

Usage & Applications : Pharmaceutical, Food, Chemical, and Cosmetic industries for powder sieving and grading

Type : Other, Industrial Turbo Sifter

Candle Perfume Filtration System

Color : Silver

Material : Stainless Steel

Power : 2.2 kW

Features : High efficiency filtration, Easy operation, Messfree filter replacement

Usage & Applications : Perfume, Oil and Liquid Filtration

Type : Other, Candle Perfume Filtration System

Aloe Vera Gel Processing Unit

Color : Silver / Metallic Finish

Material : Stainless Steel

Power : 47.5 kW

Features : Corrosion resistant, easy to install, userfriendly operation, hygienic processing, CIP (Cleaning in Place) enabled

Usage & Applications : Extraction and processing of Aloe Vera Gel for cosmetic, pharmaceutical, food & beverage industries

Type : Other, Aloe Vera Gel Processing Unit

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry