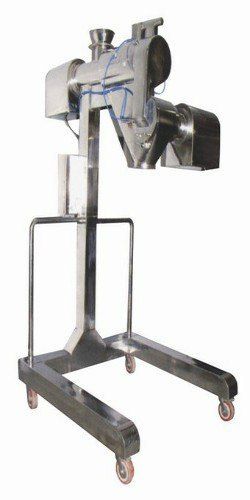

Turbo Sifter

Turbo Sifter Specification

- Frequency

- 50/60 Hz

- Temperature

- Ambient

- Features

- High sieving efficiency, GMP compliant design, Easy cleaning, Dust-free operation

- Noise Level

- <75 dB

- Usage & Applications

- Pharmaceutical, Food, Chemical, and Cosmetic industries for powder sieving and grading

- Phase

- Single / Three Phase

- Type

- Industrial Turbo Sifter

- Material

- Stainless Steel (SS304/SS316)

- Capacity

- 30-300 kg/hr (varies by model)

- Computerized

- No

- Control Mode

- Semi-Automatic

- Voltage

- 220 V / 380 V

- Power

- 1 3 HP

- Weight (kg)

- Approx. 150-350 kg

- Dimension (L*W*H)

- 1100 mm 750 mm 1650 mm

- Color

- Metallic Silver

- Mesh Size Range

- 12 to 200 mesh (customizable)

- Finishing

- Mirror / Matt finish available

- Drive Mechanism

- Vibratory/Eccentric drive

- Portability

- Portable unit

- Inlet Size

- As per customer requirement

- Safety Interlock

- Electrical interlocking system

- Discharge Height

- Approx. 650 mm

- Sieve Diameter

- Approximately 600 to 900 mm

- Mobility

- Mounted on caster wheels for easy movement

- Cleaning System

- Quick-release clamp for easy access and cleaning

- Power Supply Cord Length

- 2 meter standard (customizable)

- Product Contact Parts

- All contact parts SS316

Turbo Sifter Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Western Europe, Eastern Europe, Middle East, South America, Asia, Central America, North America, Australia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Turbo Sifter

Turbo Sifter

Compact Combine Sieving & Milling Process Technic Application & Process :

The Turbo Sifter is used to combine process for sieving and milling. The turbo sifter mainly used in pharmaceutical formulation for raw material sifting and milling process.The turbo sifter is having two chambers for sifting and milling with separate drives. The separation of coarse and fine product size happens in the sifting chamber. The sifting chambers having rotary sieve with drive so fed material powder after entering the turbo sifter is pushed towards the sieve area by screw in the sieve chamber gets sifting so, fine powder falls in to directly discharge pot. While coarse particles are proceed to the adjacent milling process. There are sieve and blades with rotary drive in milling chamber, which while rotating push and mill the material against the sieve so coarse particles are broken in to fine and falls to the discharge pot, thus attaining the uniform product size.

Salient Features :

Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Sieving and milling process are in one operation. Easy movable Easy to dismantle contact parts for clean. Enclosed drive for safety. A C frequency variable speed for sifter and milling drive.Safety Features :

Total drive transmission system enclosed Limit switch installed at the sifting and milling chamber. Overload relay Protection and Emergency stop button

Precision Sieving for Diverse Industries

The Turbo Sifter is meticulously crafted for applications in industries such as pharmaceuticals, food, chemicals, and cosmetics. Its broad mesh size range and efficient drive mechanisms guarantee precise, dust-free sieving. Users benefit from high throughput and gentle product handling, suitable even within environments demanding strict hygiene standards. The unit's adaptable design and variety of finishing options further enhance compatibility with production needs.

Engineering for Safety and Convenience

With a focus on operator safety and component longevity, the sifter includes an integrated electrical safety interlock system. Cleaning is streamlined by the quick-release clamp, facilitating rapid disassembly and reassembly. The machine's mobility on caster wheels ensures it can be relocated with ease wherever needed, supporting optimized workflow in dynamic production environments.

FAQ's of Turbo Sifter:

Q: How does the Turbo Sifter operate for powder sieving and grading?

A: The Turbo Sifter uses a vibratory or eccentric drive mechanism to efficiently separate powders based on designated mesh sizes, ensuring consistent and uniform particle distribution. It operates in a semi-automatic mode and can handle capacities from 30 to 300 kg/hr depending on the model.Q: What is the process for cleaning the Turbo Sifter after use?

A: Cleaning is straightforward thanks to the quick-release clamp design, which allows operators to access all contact parts quickly. All contact surfaces are made from SS316 stainless steel, making them non-reactive and easy to sanitize between product batches.Q: When should different mesh sizes be selected for the Turbo Sifter?

A: Mesh size selection depends on the desired particle size for your application. The sifter accommodates mesh sizes between 12 and 200, so you can choose finer or coarser separation based on product requirements. Custom mesh options can be provided to match specific process needs.Q: Where can the Turbo Sifter be deployed within my facility?

A: Thanks to its portability and caster wheels, the unit can be conveniently positioned at different locations along your production line. Its compact size and dust-free, GMP-compliant construction make it suitable for cleanroom environments and compact factory floors.Q: What safety features does the Turbo Sifter provide for operators?

A: The Turbo Sifter comes with an electrical interlocking system to prevent unauthorized or unsafe operation. Additionally, its noise level remains below 75 dB, promoting a safer and more comfortable work environment.Q: How does using this Turbo Sifter benefit my production process?

A: Employing the Turbo Sifter ensures high sieving efficiency, dust-free operation, and compliance with Good Manufacturing Practices (GMP). Its easy-clean design minimizes downtime, while its robust construction ensures long-term reliability and consistent performance across various powders and industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

Ultra Vacuum Mixer

Material : Stainless Steel

Computerized : Yes

Usage & Applications : Mixing, emulsifying, homogenizing viscous products in cosmetic, pharmaceutical, chemical, food industries

Color : Metallic Silver

Control Mode : Automatic

Dimension (L*W*H) : 1500 x 800 x 1700 mm (varies with model)

Continuous Mixer Blender System: Simplex Mixer

Material : Stainless Steel

Computerized : No

Usage & Applications : Mixing and Blending of Powders, Granules and Solids in Food, Chemical, Pharmaceutical, and Dairy Industries

Color : Silver / Metallic Finish

Control Mode : Other, Automatic / Semiautomatic

Dimension (L*W*H) : Custom / As per design

Dispohomo Reactor

Material : Stainless Steel (SS 304 / SS 316 available)

Computerized : No

Usage & Applications : Mixing, homogenizing, blending and reaction operations for pharmaceutical, chemical, cosmetic, and food industries

Color : Silver / Metallic Finish

Control Mode : Other, SemiAutomatic / Manual

Dimension (L*W*H) : Custom built as per capacity

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry