Sanitizer Tunnels

Sanitizer Tunnels Specification

- Temperature

- Ambient to 35C

- Frequency

- 50-60 Hz

- Noise Level

- <55 dB

- Usage & Applications

- Hospital/Schools/Offices/Factories/Public Places

- Features

- Motion sensor activation, mist spray, quick sterilization, non-corrosive body

- Phase

- Single / Three Phase

- Type

- Sanitizer Tunnel

- Material

- Stainless Steel / Mild Steel / Polycarbonate Panels

- Capacity

- 500-1000 persons per hour

- Computerized

- Yes

- Control Mode

- Automatic/Manual

- Voltage

- 220-240V

- Power

- 0.75-2 kW

- Weight (kg)

- 120-250 kg

- Dimension (L*W*H)

- 3000 x 1200 x 2200 mm

- Color

- White/Blue/Grey

- Entry & Exit

- Dual flap or sliding door

- Maintenance Interval

- Monthly

- Recommended Fluid Usage

- 5-10 ml/person

- Ingress Protection

- IP55

- Operating Environment

- Indoor/Outdoor

- User Interface

- Digital display with status indicators

- Water Consumption

- Minimal (adjustable spray system)

- Finish

- Corrosion resistant, powder-coated

- Relative Humidity Tolerance

- Upto 90%

- Spray Coverage

- 360-degree mist dispersal

- Safety Features

- Auto shut-off, Emergency stop

- Installation

- Ready-to-use, Plug & Play

- Sanitizing Agent

- Alcohol-based or approved disinfectant

- Disinfection Time

- 3-5 seconds per person

- Sensor Type

- Infrared Motion Sensor

- Mobility

- Caster Wheels for relocation

Sanitizer Tunnels Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Paypal, Western Union, Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Sanitizer Tunnels

Sanitizer Tunnels

Smart spray disinfection for hand washing The temperature measuring area is equipped with intelligent induction sprayer, no contact induction spraying, safety and hygiene, can carry out effective sterilization.

Aerosol disinfection type -Size 4x4x7 ,Size 7x4x7 Thermometric disinfection type- Weight 220 kg

Disinfectant food grade ,disinfectant Voltage AC 220V Using Applications- hospitals,schools,communities, supermarkets, scenic spots, shopping mall, stations, airports, factories and other public places

Rapid, Effective Disinfection for Public Spaces

Engineered for speed and efficiency, the Sanitizer Tunnel delivers thorough 360-degree mist coverage in as little as 3-5 seconds per individual. Its ready-to-use, plug & play setup provides seamless integration into a variety of venues, supporting both single and three-phase power while maintaining low water and fluid usage. The units IP55 ingress protection and up to 90% relative humidity tolerance qualify it for diverse environmental conditions.

Advanced Safety and User Experience

Safety is prioritized through automatic shut-off, infrared motion sensor activation, emergency stop, and clear digital status indicators. Dual flap or sliding doors allow controlled entry and exit, while the non-corrosive, powder-coated frame supports longevity. The systems low noise output (<55 dB) and monthly maintenance interval further enhance operational convenience.

Flexible Integration and Mobility

With robust caster wheels and a modular, corrosion-resistant build, the Sanitizer Tunnel is designed for easy relocation and suitability in spaces ranging from hospitals to schools and factories. Its adaptability is complemented by adjustable spray volumes, comprehensive 360 mist dispersal, and a broad power compatibility (220-240V, 50-60 Hz), making it a practical choice for a variety of institutional and commercial applications.

FAQs of Sanitizer Tunnels:

Q: How does the sanitizer tunnel operate to ensure complete disinfection?

A: The sanitizer tunnel uses infrared motion sensors to detect entry, automatically activating a 360-degree mist spray that disperses 5-10 ml of alcohol-based or approved disinfectant per person. This process rapidly sanitizes individuals in just 3-5 seconds per cycle, ensuring efficient and thorough coverage.Q: What kind of sanitizer or disinfectant is recommended for the tunnel?

A: The tunnel is optimized for use with alcohol-based or other approved disinfectant fluids. It delivers a controlled, minimal dose per person, ensuring safety, effective coverage, and regulatory compliance for environments such as hospitals, offices, and public spaces.Q: When should maintenance be performed on the tunnel?

A: Routine maintenance is recommended on a monthly basis. This includes checking and cleaning spray nozzles, sensors, and inspecting the mechanical and electrical systems to ensure uninterrupted and safe operation.Q: Where can this sanitizer tunnel be installed and used?

A: Installation is suitable for both indoor and outdoor environments, thanks to its IP55 ingress protection, humidity tolerance up to 90%, and robust, corrosion-resistant construction. It is commonly deployed in hospitals, schools, factories, offices, public venues, and similar high-footfall areas.Q: What is the installation and relocation process like?

A: The Sanitizer Tunnel arrives ready-to-use with plug & play connectivity. Its integrated caster wheels enable simple relocation across different areas, allowing quick redeployment as needed without complex setup or specialized tools.Q: How is user safety ensured during operation?

A: Safety features include an auto shut-off mechanism, emergency stop, low-noise operation, and clear digital display for operational status. The design prevents unauthorized entry and ensures reliable functioning in crowded, dynamic settings.Q: What are the main benefits of using this sanitizer tunnel?

A: Key benefits include efficient high-capacity disinfection (up to 1000 people per hour), fast processing time (3-5 seconds per person), minimal fluid and water usage, versatile installation, and robust safety features, all of which contribute to enhanced hygiene and operational convenience in public and commercial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

Starch Paste Preparation Kettle

Computerized : No

Voltage : 220V / 415V

Material : Stainless Steel (SS 304/316)

Color : Silver

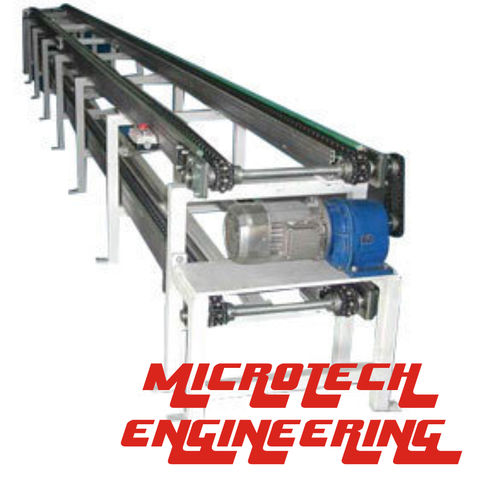

Slat Chain Conveyor

Computerized : No

Voltage : 220440 V

Material : Stainless Steel / Mild Steel

Color : Silver / Metallic Grey

Semi Automatic Liquid Filling Machines

Computerized : No

Voltage : 220V AC

Material : Stainless Steel

Color : Silver

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry