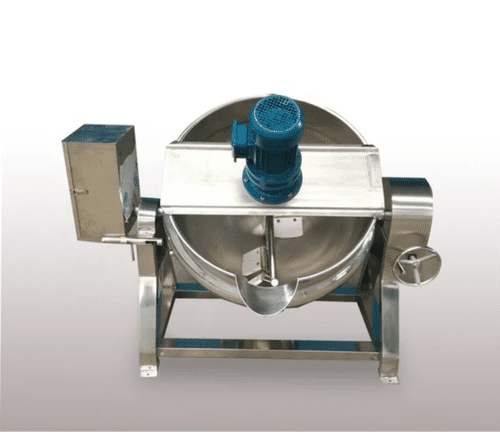

Starch Paste Preparation Kettle

Starch Paste Preparation Kettle Specification

- Usage & Applications

- Textile, Pharmaceuticals, Paper, and Food Industries for paste making and mixing

- Phase

- Single Phase / Three Phase

- Frequency

- 50/60 Hz

- Features

- Jacketed vessel, Insulated body, Tilting arrangement, Agitator, Easy operation, Corrosion Resistant

- Temperature

- Upto 120C (steam / electric heating)

- Noise Level

- Low

- Type

- Starch Paste Preparation Kettle

- Material

- Stainless Steel (SS 304/316)

- Capacity

- 50 to 500 Liters (customizable)

- Computerized

- No

- Control Mode

- Manual / Semi-automatic

- Voltage

- 220V / 415V

- Power

- 3-5 kW (vary by capacity)

- Weight (kg)

- 150-350 kg (approx., varies by size)

- Dimension (L*W*H)

- As per model (customized)

- Color

- Silver

- Compliance

- Meets cGMP and FDA standards

- Mounting

- Leg Mounted / Mobile on Wheels (optional)

- Safety

- Overheating and Pressure Safety Controls

- Insulation Material

- Rockwool/Mineral Wool

- Heating Option

- Electric / Steam / Thermic Fluid

- Cleaning

- CIP/SIP Compatible (as per model)

- Pressure Range

- Atmospheric to Low Pressure (as per requirement)

- Installation

- On-site installation and commissioning support provided

- Mixing Speed

- Variable as per application

- GMP Model

- Available

- Agitator Type

- Anchor / Paddle / Customized

- Discharge Valve

- Stainless Steel Ball/Butterfly Valve

- Surface Finish

- Mirror/Matte Finish

- Lid Type

- Hinged/Clamped Lid with Glass inspection window

Starch Paste Preparation Kettle Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Paypal, Western Union, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Starch Paste Preparation Kettle

Starch Paste Preparation Kettle

Starch Paste Preparation Technic

Application & Process :

The paste kettle is designed for preparing paste / starch / binder solution for making granules for tableting formulation and granulation . It has a universal application resulting in uniform melting.The kettle has a small cylindrical top shell with a spout for pouring out binder mass. It is provided with Anchor type beater for paste mixing with dual speed option.

Salient Features :

Capacity available in 50 Liters to 300 Liters. Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Product Bowl with Jacketing and Insulation for heating. Tilting unit for unloading.

Optional Features :

Heating Option: (1) Steam Heated (2) Electric Heated with tharmic fluid.(3) Pressurized hot water Temperature controller with sensor. Anchor stirrer with Variable speed, Pillar design kettle with anchor stirrer.

Superior Flexibility and Customization

Tailor your starch paste preparation with multiple choices in agitator design, heating method, mounting configuration, and discharge valve type. The kettles capacity, control mode, and surface finish can be precisely adapted to your operational requirements, ensuring seamless integration into diverse production environments.

Uncompromised Safety and Compliance

This kettle is engineered with rigorous safety features, including automatic overheating and pressure controls, and is available in GMP models. Meeting both cGMP and FDA standards, it guarantees quality processing for sensitive applications across various industries. Optional glass inspection windows allow safe monitoring of the process.

Efficient Process and User-Friendly Operation

Maintaining consistent temperatures up to 120C and offering variable mixing speeds, the kettle supports efficient, homogeneous paste development. The vessels jacketed, insulated body, easy-tilt function, and low noise operation maximize productivity and operator comfort. On-site installation and commissioning support is also provided to ensure smooth setup.

FAQs of Starch Paste Preparation Kettle:

Q: How is the starch paste preparation process carried out using this kettle?

A: The starch paste preparation process involves loading ingredients into the stainless steel kettle, selecting the appropriate agitator type (anchor, paddle, or customized), and utilizing variable mixing speeds. Heating is achieved via electric, steam, or thermic fluid jackets, ensuring controlled temperatures up to 120C. The integrated safety controls monitor pressure and temperature throughout the process.Q: What are the key benefits of using a starch paste preparation kettle with a jacketed and insulated body?

A: A jacketed and insulated body ensures efficient and uniform heat transfer, minimizes energy loss, maintains consistent paste temperatures, and enhances operator safety. This design helps achieve optimal paste consistency and improves energy efficiency, making the kettle suitable for continuous industrial production.Q: When should I choose a mobile on wheels mounting over a leg-mounted kettle?

A: A mobile kettle is ideal when there is a need to frequently move the equipment between processing areas or share it across multiple production lines. The leg-mounted version is better suited for fixed installations where stability is a priority. Selection depends on workflow flexibility and space utilization in your facility.Q: Where can this starch paste preparation kettle be installed?

A: This kettle can be installed in any facility engaged in textile, pharmaceutical, paper, or food processing. It fits both small and large production setups and is supported by on-site installation and commissioning services to ensure it operates as intended from the start.Q: What cleaning and maintenance options are available for the kettle?

A: Depending on the model, the kettle is compatible with CIP (Clean-in-Place) and SIP (Sterilize-in-Place) systems, allowing for efficient and thorough cleaning without manual intervention. Regular maintenance typically involves inspecting seals, safety controls, the agitator mechanism, and periodic calibration of sensors.Q: How does the variable mixing speed benefit different paste applications?

A: Variable mixing speeds accommodate a wide range of paste viscosities and processesfrom gentle blending to vigorous agitationensuring homogeneous mixing and optimal texture for every application. This versatility makes the kettle suitable for both delicate pharmaceutical pastes and robust industrial starch batches.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

Bin Blender

Computerized : No

Color : Metallic/Silver

Control Mode : Other, Manual / PLC Based

Voltage : 220380V

Material : Stainless Steel (SS 304/316L)

Double Jacket Heating Tank

Minimum Order Quantity : 01

Computerized : No

Color : Silver (Metallic Finish)

Control Mode : Manual

Voltage : 220440 V

Material : Stainless Steel (SS 304/316)

PP Cap Sealing Machine

Minimum Order Quantity : 01

Computerized : No

Color : White, Blue

Control Mode : SemiAutomatic

Voltage : 220 V

Material : Mild Steel, Stainless Steel

Semi Automatic Liquid Filling Machines

Computerized : No

Color : Silver

Control Mode : Other, Pneumatic / Manual

Voltage : 220V AC

Material : Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry