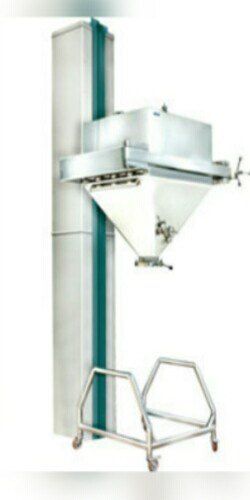

Nauta Mixer

Nauta Mixer Specification

- Temperature

- Ambient

- Frequency

- 50 Hz

- Noise Level

- Less than 70 dB

- Phase

- Three Phase

- Features

- Efficient mixing, uniform blending, easy cleaning, low maintenance

- Usage & Applications

- Mixing powder, granules, chemicals, food products, pharmaceuticals

- Type

- Nauta Mixer

- Material

- Stainless Steel

- Capacity

- 500 Liters

- Computerized

- No

- Control Mode

- Manual

- Voltage

- 415 V

- Power

- 7.5 kW

- Weight (kg)

- 1300 kg

- Dimension (L*W*H)

- 2200 mm x 1500 mm x 3200 mm

- Color

- Metallic Silver

- Speed

- 18 RPM (screw rotation)

- Mixing Principle

- Conical Screw Mixer - Gentle Rotation

- Filling Ratio

- Maximum 60% of Total Volume

- Discharge Valve Type

- Butterfly Valve

- Hopper Opening Size

- 500 mm

- Motor Protection

- IP55

- Surface Finish

- Mirror Polished

- Safety Features

- Overload protection, emergency stop switch

- Batch Duration

- 15 to 30 minutes per batch

- Drive Mechanism

- Gearbox with Motor

- Installation

- Floor Mounted

- Seal Type

- Mechanical Seal

Nauta Mixer Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Western Union, Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Nauta Mixer

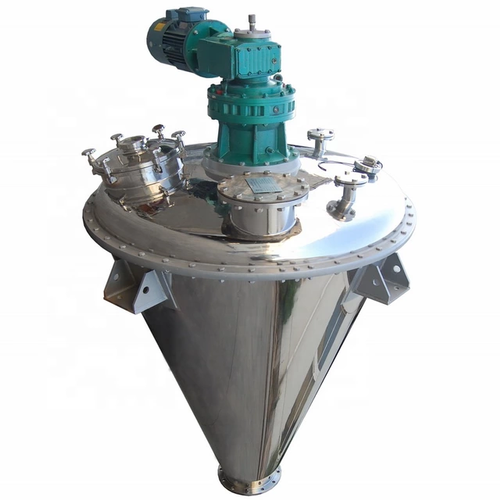

Double Screw Fertilizer Powder Cone Ribbon Mixer/conical Screw Ribbon Blender/nauta Mixer

The material is made to conduct a compound motion in the cone because of the rotation and revolution of the screws.The effected motions include: 1.The revolution of the screw along the wall making the material conduct a circumferential motion; 2.The rotation of the screw making the material rise along the screw from the cone bottom; 3.The compound motion of the rotation and revolution of the screws making partial,material can be absorbed into the screw cylindroid meanwhile,under the action of centrifugal force,the partial material in the screw cylindroid discharges radially. 4.The rised material drops under its sole weight.the four kinds of motions effect convection,shearing,diffusion in the cone ,thus quick and even mixing can be achieved. Applications It is suitable for chemical industry,pharmaceutical industry,pesticide,dyestuff,petroleum industry,metallurgical industry,construction material and etc.Such as in the mixing,reaction,drying,cooling of powder and powder(solid-solid),powder and liquid(solid-liquid),liquid-liquid(liquid-liquid).

Superior Mixing Principle

The Nauta Mixer utilizes a conical screw mechanism, gently rotating at 18 RPM to assure homogeneous mixing and minimal material degradation. This principle is ideal for handling sensitive powders and granules, guaranteeing uniform blending with reliable batch consistency. The design supports a maximum filling ratio of 60%, optimizing both performance and productivity without compromising on quality.

Design and Safety Features

Engineered with a robust stainless steel structure and a precise mirror polished finish, the Nauta Mixer ensures sanitary operation and easy cleaning. Key safety features include overload protection and an emergency stop switch, making this equipment both user-friendly and compliant with high safety standards. The butterfly valve discharge, mechanical sealing, and IP55 motor protection fortify reliable and safe production processes.

Operational Efficiency and Convenience

With a 7.5 kW geared motor, the mixer enables a batch duration of just 15 to 30 minutes and can hold up to 500 liters. Manual control offers straightforward operation, while the 500 mm hopper opening provides ample access for easy loading and cleaning. Low maintenance requirements and a noise level below 70 dB contribute to quiet, continuous operations in various settings from food to pharmaceutical industries.

FAQ's of Nauta Mixer:

Q: How does the Nauta Mixer ensure gentle yet effective mixing?

A: The Nauta Mixer employs a conical screw rotating at 18 RPM, which lifts and folds the material within a conical vessel. This gentle rotation preserves sensitive materials, prevents degradation, and achieves uniform blending across batches.Q: What types of materials can be processed in this mixer?

A: This mixer is suitable for mixing powders, granules, chemicals, food products, and pharmaceuticals, making it highly versatile for diverse industrial applications.Q: When is the optimal time for cleaning and how is it accomplished?

A: Cleaning is recommended after each batch or when product types change. The mirror polished stainless steel surface and large 500 mm hopper opening permit easy access and thorough cleaning, ensuring hygiene and minimizing downtime.Q: Where is this Nauta Mixer typically installed?

A: The mixer is floor-mounted, making it suitable for installation in industrial environments such as chemical plants, food processing units, and pharmaceutical manufacturing facilities throughout India.Q: What safety measures are integrated into the mixer?

A: This model is equipped with overload protection, an emergency stop switch, and IP55-rated motor protection to ensure operational safety and compliance with industrial safety standards.Q: How long does a typical mixing process take and what is the maximum batch size?

A: Each batch requires approximately 15 to 30 minutes for complete mixing, with a maximum filling ratio of 60% of the total 500-liter vessel volume to ensure optimal performance and uniformity.Q: What are the key benefits of using this mixer in production lines?

A: Key benefits include efficient and uniform mixing, gentle material handling, easy cleaning, low maintenance, low operational noise, and compliance with safety and hygiene requirements, driving productivity and ensuring product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

Ointment Plant

Weight (kg) : 2200 4000 kg (Approx.)

Power : 5 to 22 kW (Depending on Batch Size)

Usage & Applications : Mixing, preparation, and manufacturing of ointments, gels, creams

Capacity : 50 to 1000 Kg per batch

Phase : 3 Phase

Voltage : 220 V / 380 V

Homeopathic Liquid syrup Making Machine

Weight (kg) : 5502500 kg (Depending on model)

Power : 215 kW

Usage & Applications : Mixing, blending, and homogenizing homeopathic liquid syrups

Capacity : 505000 Liters per batch

Phase : Single phase/Three phase

Voltage : 220V/380V

Bin Blender

Weight (kg) : Approx. 3501500 kg

Power : 27 kW

Usage & Applications : Mixing, blending dry powders and granules for pharmaceuticals, chemicals, and food processing industries

Capacity : 50 to 1200 Liters

Phase : Single/Three Phase

Voltage : 220380V

Toothpaste Transfer Pump

Weight (kg) : 110150 kg

Power : 25 HP

Usage & Applications : Used for transferring toothpaste, cream, gel, and similar viscous products in cosmetic and pharmaceutical industries.

Capacity : Up to 2 Ton/Hour

Phase : Single/Three Phase

Voltage : 220240 V

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry