Homeopathic Liquid syrup Making Machine

Homeopathic Liquid syrup Making Machine Specification

- Phase

- Single phase/Three phase

- Features

- GMP compliant, sanitary design, easy cleaning, precise control system

- Noise Level

- <75 dB

- Frequency

- 50/60 Hz

- Usage & Applications

- Mixing, blending, and homogenizing homeopathic liquid syrups

- Temperature

- Ambient to 120C (Adjustable)

- Type

- Homeopathic Liquid Syrup Making Machine

- Material

- Stainless Steel (SS 316/SS 304)

- Capacity

- 50-5000 Liters per batch

- Computerized

- Yes

- Control Mode

- Automatic & Manual

- Voltage

- 220V/380V

- Power

- 2-15 kW

- Weight (kg)

- 550-2500 kg (Depending on model)

- Dimension (L*W*H)

- Customized as per capacity

- Color

- Silver/Grey

Homeopathic Liquid syrup Making Machine Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Western Union, Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Western Europe, Australia, South America, Eastern Europe, Middle East, Africa, Central America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Homeopathic Liquid syrup Making Machine

homeopathic liquid medicine making machineGmp modelSs 316Ss 304Microtech has been designed & manufacturing preparation vessels and has consolidated a process knowledge concerning sterile injectable solution, dispersions, ophthalmic products, syrup and suppositories.

Preparation Vessels & Tank :

Extremely hygienic processing. Least manual handling. Design compliance with cGMP Capacity up to 10,000 Liter. Product Contact AISI 316L Atmospheric, Vacuum or Pressure Operation. Jacket for heating & cooling. Vessel Inside Pressure (-1 /+2 Bar) Heating Jacket Pressure (-1 /+6 bar) Heating by steam or hot water circulation. Thermal Insulated.

Advanced Technology Meets Homeopathic Precision

Our machine incorporates premium engineering, featuring customizable agitators, precise temperature control, and a robust Siemens/ABB mixer motor. With computerization and automation options, it seamlessly fits facilities producing syrups, nutraceuticals, or herbal extracts, enhancing product consistency and process efficiency while adhering to GMP standards.

Designed for Safety and Ease of Maintenance

Equipped with essential safety featuresincluding an interlock system, emergency stop, and overload protectionthis unit prioritizes operator safety. The sanitary design, together with CIP and SIP support, facilitates easy and thorough cleaning, reducing downtime in production and maintaining stringent hygiene levels.

FAQs of Homeopathic Liquid syrup Making Machine:

Q: How does the agitator type affect the mixing process in this syrup making machine?

A: The agitator type (Anchor, Paddle, or Turbine) is selected based on your application needs. Anchor agitators are ideal for viscous syrups, paddle for gentle blending, and turbine for fast, homogeneous mixing. Choosing the right agitator ensures efficient dissolution and uniformity of the batch.Q: What safety features are integrated into the homeopathic syrup making machine?

A: This machine includes an interlock system, emergency stop button, and overload protection. These features work together to protect both the operator and the equipment, preventing accidental start-ups, halting operations in emergencies, and safeguarding against electrical overloads.Q: When and where is the heating system required for this machine?

A: The optional heating system, available as steam or electrically jacketed, is required when the formulation process demands controlled temperaturesuch as dissolving active ingredients or maintaining syrup consistency. The heating option suits production lines needing precise thermal regulation during mixing.Q: What is the process of cleaning and maintaining this machine?

A: Cleaning is facilitated through Clean-In-Place (CIP) and Steam-In-Place (SIP) systems. These automated processes ensure interior surfaces are sanitized and sterilized without manual intervention, significantly reducing contamination risk and simplifying maintenance routines.Q: How can the machine be installed and operated on-site?

A: This machine comes in plug-and-play supply condition, with options for floor mounting or skid mounting for modular setups. Our team provides on-site installation and after-sales support, ensuring it operates efficiently from day one.Q: What are the main benefits of using this syrup making machine for homeopathic formulations?

A: Main benefits include precise control over mixing speed and temperature, GMP/cGMP/CE compliance, sanitary and easy-to-clean design, automation capabilities, and reliable safety systemsresulting in consistently high-quality syrup and reduced operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

Starch Paste Preparation Kettle

Material : Stainless Steel (SS 304/316)

Type : Other, Starch Paste Preparation Kettle

Capacity : 50 to 500 Liters (customizable)

Control Mode : Other, Manual / Semiautomatic

Dimension (L*W*H) : As per model (customized)

Weight (kg) : 150350 kg (approx., varies by size)

Intank Homogenizer

Material : Stainless Steel

Type : Other, Intank Homogenizer

Capacity : 505000 Liters (customizable)

Control Mode : Manual

Dimension (L*W*H) : Customized

Weight (kg) : 1801200 kg

Candle Perfume Filtration System

Material : Stainless Steel

Type : Other, Candle Perfume Filtration System

Capacity : 1000 Liters/Hour

Control Mode : Manual

Dimension (L*W*H) : 1200 x 800 x 1500 mm

Weight (kg) : 230 kg

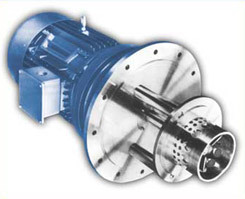

Bottom Entry Shear Mixer

Material : STAINLESS STEEL

Type : Other

Capacity : 100 Kg/hr

Control Mode : Automatic

Dimension (L*W*H) : 100*100*150 Centimeter (cm)

Weight (kg) : 80 Kilograms (kg)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry