MILK SILO

MILK SILO Specification

- Cleaning Method

- CIP (Clean-In-Place) compatible

- Flow Rate

- Up to 10,000 LPH or more

- Capacity

- 1000 Litres to 30000 Litres

- Pressure

- Atmospheric

- Connecting Type

- Flanged and threaded connections

- Media Type

- Milk

- Temperature Range

- 2C to 6C (milk storage)

- Condition

- New

- Material

- Stainless Steel (SS 304/316)

- Diameter

- As per customer requirements (typically 1000 mm - 3000 mm)

- Construction

- Double Walled with Insulation

- Weight

- Varies as per capacity and design

- Shape

- Cylindrical, Vertical

- Feature

- Vertical storage tank for milk collection and chilling

- Usage/Application

- Milk Collection, Processing, and Chilling

- Temperature Gauge

- Provided

- Cleaning Access

- Removable top cover or manhole for manual cleaning

- Surface Finish

- Mirror or matt finish to dairy standards

- Insulation Material

- Polyurethane Foam (PUF) or Mineral Wool

- Standards

- Conforms to 3A, ISI, and international dairy standards

- Level Indicator

- Provided

- Agitator

- Stainless steel paddle-type for homogeneity

- Accessories

- Spray ball for CIP, lifting lugs, inlet pipe, outlet pipe, sampling valve

- Manhole

- Hygienic manhole with cover

- Power Supply for Agitator

- Single Phase/ Three Phase as required

- Discharge Valve

- Butterfly or ball valve, SS construction

- Legs/Base

- Adjustable stainless steel legs with mounting plates

MILK SILO Trade Information

- Payment Terms

- Western Union, Paypal, Telegraphic Transfer (T/T)

- Supply Ability

- 1 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Packaging Details

- WOODEN BOX

- Main Export Market(s)

- Australia, Eastern Europe, Central America, Middle East, South America, Western Europe, Asia, North America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2008

About MILK SILO

MILK SILO

Understanding the requirements and necessities of various industrial purpose, our company is also engaged in manufacturing and supplying an excellent quality of Milk Silo in the market. With the help of advanced machinery and latest technology, our experts manufacture these silos using utmost stainless steel that is sourced from the well known vendor base. Used in large dairy plants for storing milk at low temperature, this Milk Silo can be availed from us in various sizes and storage capacities.

FEATURES

· Stores milk in 4 degree of temperature for up to 24 hrs

· Precise dimensions

· Sturdy construction

· Corrosion resistance

· High tensile strength

· For all dry free-flowing materials

· Rigid and robust in construction

· Made in profiled galvanized heavy sheet steel metal or stainless steel

· Complete-knock-down (CKD)

· Low transport costs

· Available in smooth surface and corrugated walls

· Sanitary look

· CNC production technology and modular system made easy for erection

SPECIFICATIONS

§ Thickness: 2-10mm

§ Size: Customized

MATERIAL

· Stainless steel

· Brand

Robust Milk Storage and Collection

Our vertical Milk Silo provides secure and compliant storage for large volumes of milk. With atmospheric pressure and advanced insulation, it keeps milk fresh between 2C to 6C, meeting stringent dairy requirements. The double-walled construction and precision-crafted accessories support hygienic processing and efficient milk movement.

Enhanced Cleaning and Maintenance

Designed for seamless cleaning, the silo offers Clean-In-Place (CIP) compatibility, a hygienic manhole, removable top cover, and spray ball accessories. These features ensure thorough sanitation and simplify manual or automated cleaning, essential for maintaining product safety and operational efficiency.

Custom-Built to Meet Dairy Demands

Available in multiple capacities and diameters, our Milk Silo can be tailored to meet specific production requirements. Choose between mirror or matt finishes, insulation materials, and connection types to suit your process needs. Reliable construction ensures long-lasting performance for dealers, manufacturers, and retailers.

FAQs of MILK SILO:

Q: How does the Milk Silo maintain milk quality during storage?

A: The Milk Silo features double-walled insulation with Polyurethane Foam (PUF) or Mineral Wool, maintaining temperatures between 2C to 6C. Its stainless steel construction, paddle-type agitator, and CIP system preserve milk homogeneity and hygiene, ensuring quality from collection through storage.Q: What types of cleaning processes can be used with this Milk Silo?

A: The Milk Silo supports Clean-In-Place (CIP) cleaning using an integrated spray ball, and also offers access through a removable top cover or hygienic manhole for manual cleaning. This dual-access ensures comprehensive sanitation aligning with dairy industry standards.Q: When should a user select mirror or matt finish for the Milk Silo?

A: The choice between mirror or matt surface finishes depends on facility preferences and cleaning protocols. Mirror finishes facilitate easier cleaning and reduce residue buildup, while matt finishes offer minimal glare and can blend with specific factory environments. Both conform to dairy standards.Q: Where can this Milk Silo be installed and used?

A: The silo is designed for installation in dairy farms, collection centers, processing plants, and chilled storage facilities across India. Its adjustable stainless steel legs with mounting plates enable secure placement on varied surfaces, accommodating operations from small dairies to large industrial units.Q: What are the benefits of the stainless steel paddle-type agitator?

A: The stainless steel paddle-type agitator ensures homogeneity within the milk silo, preventing cream separation and maintaining consistent quality. Its robust construction withstands frequent use, while single or three-phase power options provide operational flexibility.Q: How does the Milk Silo conform to international dairy standards?

A: The Milk Silo is manufactured in compliance with 3A, ISI, and international dairy standards. Features such as hygienic manholes, compliant surface finishes, CIP compatibility, and safe discharge valves ensure regulatory adherence and product safety for both local and global markets.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in food processing machines Category

Mixing Blending Tank

Shape : standard

Feature : Mixing Blending Tank (vessel)

Weight : standard Kilograms (kg)

Construction : Wire Mesh

Condition : New

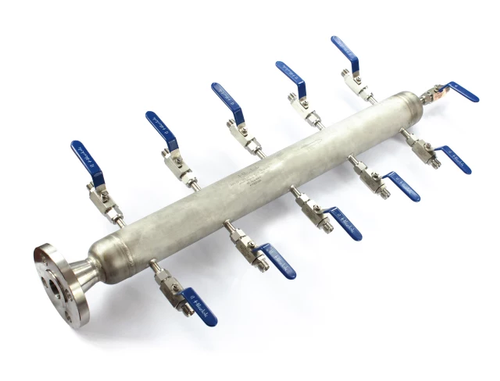

Air Distribution Headers

Shape : Round, Cylindrical

Feature : Uniform Air Distribution, Leak Proof Design, Corrosion Resistant

Weight : Depends on size and material

Construction : Other, Seamless Welded Construction

Condition : New

Connecting Type : Other, Flanged, Threaded, Welded

BOILING KETTLES

Shape : Vertical Cylindrical

Feature : Highly efficient, energysaving, and robust design

Weight : Depends on capacity and model

Construction : Other, Double Jacketed with Insulation

Condition : New

Connecting Type : Other, Flanged / Threaded / Welded (as required)

SKID MOUNTED MILK CHILLING SYSTEM

Shape : Rectangular/Custom Skid layout

Feature : Rapid chilling, compact skidmounted design, integrated cooling system, easy to install and operate, hygienic and easy to clean.

Weight : Approx. 300800 kg (depending on capacity)

Construction : Other, Skid Mounted with robust stainless steel frame

Condition : New

Connecting Type : Other, Triclamp/Flanged connections

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry