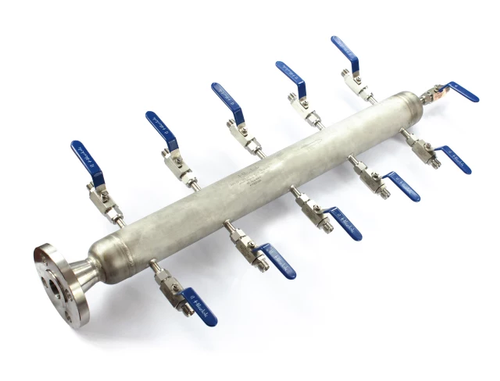

Air Distribution Headers

Air Distribution Headers Specification

- Connecting Type

- Flanged, Threaded, Welded

- Filtration Grade

- Pre-Filter

- Cleaning Method

- Manual or Automatic

- Media Type

- Compressed Air

- Filter Type

- Header Type

- Efficiency (%)

- Up to 99%

- Pressure

- Up to 10 bar

- Temperature Range

- -10C to 80C

- Capacity

- As per Plant Requirement

- Flow Rate

- Based on design specification

- Condition

- New

- Material

- Stainless Steel, Mild Steel, PVC (as per requirement)

- Diameter

- 2 Inch to 24 Inch (customizable)

- Construction

- Seamless Welded Construction

- Medium Filter

- Air

- Weight

- Depends on size and material

- Shape

- Round, Cylindrical

- Feature

- Uniform Air Distribution, Leak Proof Design, Corrosion Resistant

- Surface Finish

- Polished / Coated (as required)

- Number of Outlets

- Configurable

- Operating Position

- Horizontal or Vertical

- Corrosion Protection

- Epoxy Paint or Hot Dip Galvanized (as required)

- End Connections

- Socket Weld, Butt Weld, Flanged

- Test Pressure

- Hydro Tested at 1.5 times Design Pressure

- Application

- Compressed Air Distribution in Industrial Systems

- Installation

- Easy to Install and Maintain

Air Distribution Headers Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Western Union, Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1000 Per Year

- Delivery Time

- 1 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Air Distribution Headers

Superior Air Distribution Performance

Our Air Distribution Headers deliver reliable, uniform air supply with each outlet, enhancing the efficiency of industrial pneumatic systems. Precision engineering and seamless welded construction provide leak-proof integrity and minimal pressure loss, ensuring optimal performance across all applications.

Customizable Design to Suit Every Need

Tailor your air header with configurable outlets, a wide range of diameters (2" to 24"), and choice of materials-stainless steel, mild steel, or PVC. End connections are available in socket weld, butt weld, or flanged formats, and both horizontal and vertical installation options can be easily accommodated.

Robust Corrosion Protection

For extended service life in harsh environments, the headers are finished with high-quality epoxy paint or hot-dip galvanized coating, as per your requirements. These treatments resist rust and chemical damage, making them ideal for India's diverse industrial conditions.

FAQ's of Air Distribution Headers:

Q: How are Air Distribution Headers installed in an industrial setting?

A: Air Distribution Headers are designed for straightforward installation in both horizontal and vertical positions. They support multiple end connection types including socket weld, butt weld, and flanged, making integration into existing compressed air distribution systems uncomplicated and efficient.Q: What material options are available for these Air Distribution Headers?

A: These headers can be fabricated from stainless steel, mild steel, or PVC, depending on plant requirements and environmental conditions. Each material provides distinct advantages in terms of strength, durability, and corrosion resistance.Q: When should epoxy paint or hot dip galvanized coatings be specified?

A: Choose epoxy paint for enhanced resistance against chemical corrosion, or opt for hot dip galvanization when superior protection against atmospheric rust is needed. Selection depends on the particular demands of your industrial environment.Q: Where can these headers be used in compressed air systems?

A: They are suitable for use in any industrial application requiring uniform compressed air distribution, and can be installed wherever consistent air pressure and flow are critical-from manufacturing floors to processing plants.Q: What is the process for pressure testing these headers?

A: Each header undergoes a hydrostatic test at 1.5 times its design pressure, ensuring structural integrity and leak-proof performance before installation in any operational environment.Q: How does the filtration function benefit compressed air systems?

A: Integrated pre-filtration (up to 99% efficiency) helps remove particulates from the supplied air, safeguarding equipment, improving overall system efficiency, and reducing maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in food processing machines Category

Mixing Blending Tank

Diameter : standard Millimeter (mm)

Weight : standard Kilograms (kg)

Feature : Mixing Blending Tank (vessel)

Construction : Wire Mesh

Condition : New

Shape : standard

FOOD PULVERIZER

Diameter : 220 mm

Weight : 60 kg

Feature : High grinding efficiency, Stainless steel construction, Easy to operate, Low maintenance

Construction : Other, Robust and compact

Condition : New

Shape : Rectangular

HANDING VERTICAL HIGH SHEAR MIXER

Diameter : Customizable as per model/specification

Weight : Varies based on capacity and model

Feature : High Shear Mixing, Vertical Design, Efficient Homogenization

Construction : Other, Vertical, Heavyduty Frame

Condition : New

Shape : Vertical Cylindrical

HEMI SPHERICAL KETTLES

Diameter : 500 mm to 3000 mm (customized)

Weight : Variable as per capacity and size

Feature : Jacketed for uniform heating; robust stirrer mechanism; Spherical bottom design for optimal mixing; Highgrade insulation

Construction : Other, Heavyduty hemispherical welded body

Condition : New

Shape : Hemisphere / Spherical

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry