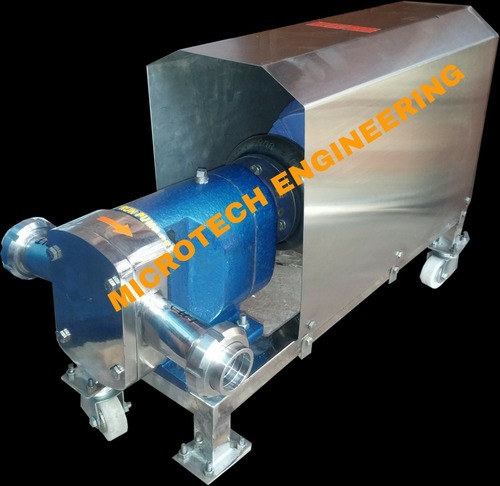

Cosmetic Cream Transfer Pump

Cosmetic Cream Transfer Pump Specification

- Features

- Corrosion-resistant, Easy cleaning, Compact design

- Max Suction

- 5 meters

- Flow Rate

- 1000 LPH

- Head Size

- 30 meters

- Working Temperature

- 0C to 80C

- Mounting Type

- Base Mounted

- Theory

- Centrifugal Pump

- Caliber

- 40 mm

- Noise Level

- <70 dB

- Inlet/Outlet

- 1.5 inch BSP

- Voltage

- 220V

- Discharge Pressure

- 3 Bar

- Speed

- 2800 RPM

- Control System

- Manual

- Frequency

- 50 Hz

- Material

- Stainless Steel 304

- Structure

- Horizontal

- Power

- 1.5 HP

- Standard

- ISI Certified

- Fuel Type

- Electric

- Pressure

- 3 Bar

- Usage

- Cosmetic Cream Transfer

- Application

- Pharmaceutical, Cosmetic, Food

- Suction Type

- Positive Suction

- Seals Type

- Mechanical Seal

- Priming

- Self-Priming

- Pump Type

- Centrifugal

- Capacity

- 1000 LPH

- Finish

- Mirror polished

- Temperature Resistance

- Up to 80°C

- Motor Protection

- IP55 Rated

- Connection Type

- Threaded

- Vibration Level

- Low

- Maintenance

- Low maintenance requirements

- Weight

- Approx 25 kg

- Cleaning

- CIP (Clean-in-Place) Compatible

Cosmetic Cream Transfer Pump Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Telegraphic Transfer (T/T), Western Union, Paypal, Letter of Credit (L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1000 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Cosmetic Cream Transfer Pump

Cosmetic Cream Transfer Pump

Microtech engineering

Lobe pumps are used in a variety of industries including, pulp and paper, chemical, food, beverage, Pharmaceutical, and biotechnology. They are popular in these Diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics.These pumps offer a variety of lobe options including single, biwing, tri-lobe (shown), and multi-lobe.Rotary lobe pumps are Non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self- priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous.

Premium Stainless Steel Construction

Fabricated from Stainless Steel 304, this cosmetic cream transfer pump combines durability with a hygienic mirror-polished finish. Recommended for industries such as cosmetics, pharmaceuticals, and food processing, its resistance to corrosion and ease of cleaning ensure reliable performance and compliance with strict hygiene regulations.

Reliable and Efficient Operation

Operating at up to 1000 LPH and capable of handling heads up to 30 meters, the centrifugal pump is equipped with mechanical seals, a self-priming feature, and IP55 motor protection. Its low vibration and noise levels, along with a base-mounted compact structure, guarantee stable operation and low maintenance requirements over time.

Versatile Application and User-Friendly Maintenance

This pump is specifically designed for easy integration in various industrial settings. The threaded connections (1.5 inch BSP), compatibility with 220V/50 Hz power supplies, and clean-in-place (CIP) compatibility make it straightforward to install, operate, and maintain. Manual control and easy-to-access components simplify regular use and upkeep.

FAQ's of Cosmetic Cream Transfer Pump:

Q: How does the Cosmetic Cream Transfer Pump handle viscous products during the transfer process?

A: The pump utilizes centrifugal force and a self-priming mechanism, allowing the efficient transfer of viscous cosmetic creams. Stainless Steel 304 construction and a robust mechanical seal prevent leakage and maintain hygienic conditions during operation.Q: What are the main benefits of using this pump for cosmetic or pharmaceutical applications?

A: Key benefits include corrosion resistance, an easy-to-clean mirror-polished finish, compliance with ISI standards, reliable IP55 motor protection, and low maintenance. Its design minimizes contamination risks while efficiently transferring sensitive products.Q: When should the pump be cleaned, and what cleaning process is recommended?

A: Cleaning should follow every production batch or as per your facility's hygiene schedule. As the pump is Clean-in-Place (CIP) compatible, internal cleaning can be conducted without disassembling the unit, streamlining maintenance and reducing downtime.Q: Where can this pump be installed within a production facility?

A: Thanks to its compact, base-mounted horizontal design and threaded inlet/outlet connections, the pump suits process lines in cosmetic, pharmaceutical, and food plants. It can be installed wherever there's a need to transfer creams or viscous liquids-typically between mixing vessels and filling stations.Q: What makes this pump low maintenance and how does it minimize operational interruptions?

A: The centrifugal design, mechanical seals, and stainless steel build result in fewer wear parts and resist product buildup. Its low vibration, easy cleaning, and robust construction contribute to reduced maintenance frequency and less downtime.Q: How is temperature resistance ensured during high-temperature product transfers?

A: The pump is engineered for working temperatures from 0C up to 80C, using materials and seals that maintain integrity and performance across this range. This allows safe handling of cosmetic creams even when processed at elevated temperatures.Q: What usage scenarios are ideal for this pump, and who can get it in India?

A: Optimized for transferring creams, ointments, and similar products in pharmaceutical, cosmetic, and food production lines, the pump is available via dealers, distributors, exporters, fabricators, manufacturers, retailers, suppliers, traders, and wholesalers across India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lobe Pump Category

YOGURT TRANSFER PUMP

Minimum Order Quantity : 01 Piece

Usage : Other, Dairy, Yogurt, Food Processing

Pressure : Other, Max 4 Bar

Material : Sanitary Stainless Steel (SS304/SS316)

Theory : Centrifugal Pump

Pump Type : Other, Sanitary Transfer Pump

Horizontal Rotary Lobe Pump

Minimum Order Quantity : 01

Usage : Other, Industrial Liquid Transfer

Pressure : Other, Up to 1.2 MPa

Material : SS304/SS316

Theory : Other, Rotary Lobe

Pump Type : Other, Horizontal Rotary Lobe Pump

Tooth Paste Transfer Pump

Minimum Order Quantity : 01 Piece

Usage : Other, Industrial, Toothpaste Transfer

Pressure : Other, Up to 3 Bar

Material : Stainless Steel (SS316/SS304)

Theory : Centrifugal Pump

Pump Type : Other, Sanitary Transfer Pump

Coffee Transfer Pump

Usage : Other, Coffee, Milk, Liquid Transfer

Pressure : Other, Up to 3 bar

Material : Stainless Steel (SS304 / SS316)

Theory : Centrifugal Pump

Pump Type : Other, Sanitary Pump

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry