WATER PROOFING CHEMICAL PLANT

WATER PROOFING CHEMICAL PLANT Specification

- Power

- 15-30 kW

- Condition

- New

- Product Type

- Water Proofing Chemical Plant

- General Use

- Production of waterproofing chemicals

- Material

- Stainless Steel (SS304/SS316)

- Capacity

- 1000-5000 L/Batch

- Weight (kg)

- 2500

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Available

- Mixer Type

- High Speed Mixer

- Shaft

- Single / Double Shaft Agitator

- Drive Type

- Electric

- Voltage

- 415 V

- Motor

- Standard Industrial Motor

- Dimension (L*W*H)

- 5200mm x 2400mm x 3400mm

- Feature

- Corrosion resistant, High efficiency, Easy operation

- Color

- Industrial Grey / Custom

WATER PROOFING CHEMICAL PLANT Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Western Union, Paypal, Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About WATER PROOFING CHEMICAL PLANT

Innovative Mixing and Heating Capabilities

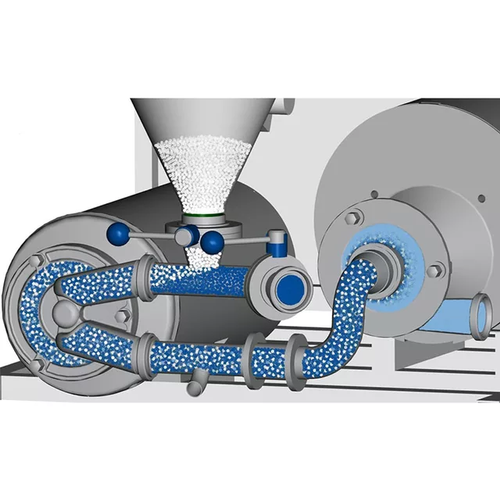

The plant features a high-speed mixer with variable speed adjustment up to 1450 RPM, and a multi-impeller design with scraper technology for enhanced blending efficiency. Optional heated jackets permit the use of steam or hot oil to process different formulations, ensuring consistency across various batch sizes and types.

Advanced Control and Safety Systems

Operators benefit from a digital touch screen display with HMI and PLC control, simplifying process adjustments and recipe management. Integrated overload protection and emergency stop ensure operator and equipment safety, making the plant both reliable and easy to use in demanding industrial environments.

Versatile Production and Low Maintenance

Designed to handle input granular or solid materials up to 50 mm, the plant supports batch sizes from 1000 to 5000 L, delivering productivity along with low-maintenance and easy-to-clean surfaces. With quiet operation and robust stainless steel construction, it suits continuous use in various industrial settings.

FAQs of WATER PROOFING CHEMICAL PLANT:

Q: How does the WATER PROOFING CHEMICAL PLANT ensure efficient mixing of materials?

A: The plant employs a high-speed mixer with variable speed adjustment up to 1450 RPM and a multi-impeller agitator with scraper, ensuring homogeneous blending of ingredients regardless of their form or viscosity.Q: What safety features are integrated into the operation of this plant?

A: For operator and equipment protection, the plant includes overload protection mechanisms and an emergency stop function, providing rapid shutdown capabilities during any irregular event.Q: When is it necessary to use the optional heating system in production?

A: The optional steam or hot oil jacket heating system is recommended for formulations that require temperature control, such as those involving temperature-sensitive chemicals or requiring enhanced solubility and reactivity.Q: Where can this waterproofing chemical plant be installed?

A: This plant is suitable for installation in a variety of industrial environments, including construction chemical production units, waterproofing solution manufacturing facilities, and other chemical processing sites across India.Q: What is the process for producing waterproofing chemicals in this plant?

A: Production involves feeding raw solid or granular materials (up to 50 mm) into the mixer, followed by controlled mixing, optional heating, batch processing (3090 minutes depending on formulation), and finally discharge via a bottom valve outlet.Q: How user-friendly is the operation of the plant?

A: Operation is streamlined through a digital touch screen interface with HMI and PLC control, enabling easy management of settings, batch parameters, and diagnostics with minimal manual intervention.Q: What are the key benefits of this waterproofing chemical plant for industries?

A: Industries benefit from high efficiency, robust safety standards, automated controls, short batch times, low noise levels, and ease of maintenance given the corrosion-resistant stainless steel construction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Processing Plants Category

Chemical Re-circulation Process Pump

Shaft : Other, High Strength Stainless Steel

Drive Type : Other, Direct Coupled

Material : Other, Cast Iron / Stainless Steel

Voltage : 380415 V

Automatic : Other, SemiAutomatic

Power : Up to 15 HP

Grease Homogenize Mixer

Shaft : Other, Single or Double Shaft (As per order)

Drive Type : Electric

Material : Other, Stainless Steel (SS304/SS316)

Voltage : 220V/380V/415V, 50/60Hz

Automatic : Yes

Power : 550 kW (Depending on size/capacity)

Sanitizer Making Machine

Shaft : Other, Stainless Steel Shaft

Drive Type : Other, Electric Drive

Material : Stainless Steel

Voltage : 220 440 V

Automatic : Yes

Power : 3 kW

Sanitizer Filter Press

Shaft : Other, SS Shaft

Drive Type : Electric

Material : Other, Stainless Steel (SS 304/316)

Voltage : 220240V, 50 Hz

Automatic : Other, Semi Automatic

Power : 12 HP

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry