Sanitizer Filter Press

Sanitizer Filter Press Specification

- Condition

- New

- Power

- 1-2 HP

- Product Type

- Sanitizer Filter Press

- General Use

- Sanitizer filtration and clarification

- Material

- Stainless Steel (SS 304/316)

- Capacity

- 100-500 Liters/Hour (customizable)

- Weight (kg)

- 120 kg (approx.)

- Computerized

- No

- Automatic

- Semi Automatic

- PLC Control

- No

- Mixer Type

- Plate and Frame

- Shaft

- SS Shaft

- Drive Type

- Electric

- Voltage

- 220-240V, 50 Hz

- Motor

- Crompton/ABB or equivalent

- Dimension (L*W*H)

- 1100 mm x 500 mm x 900 mm

- Feature

- Leak proof, Easy to operate, Corrosion resistant

- Color

- Silver

Sanitizer Filter Press Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Letter of Credit (L/C), Paypal, Western Union, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- 100 Per Year

- Delivery Time

- 1 Months

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, North America, South America, Western Europe, Middle East, Central America, Eastern Europe, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Sanitizer Filter Press

We are a trusted manufacturer and supplier of top grade Pumps and Process Control Instruments. With a premier aim to cater to the varied demands and requirements of our client in an efficient manner, we offer a comprehensive array of products comprising Transfer Pump, Polypropylene Pump, Stainless Steel Self Priming Pump, Filter Pump, Magnetic Drive Pump, Dosing Pump and Process Control Instruments. All these products are developed in compliance with the international quality standards.

Our firm has crossed milestones of success in the industry by offering quality products that are known for an optimal functionality and long service life. The professionals employed by our firm use the latest technological advancements to fabricate all our products. Apart from this, we provide prompt after sales support, installation training, on site support and operational training. Further, we are backed by a wide distribution network that assists us to provide prompt deliveries of consignments to our clients.

Superior Filtration Precision

Achieve meticulous filtration accuracy up to 5 microns, ensuring that sanitizer liquids and disinfectant solutions are purified to pharmaceutical-grade standards. The plate-and-frame design facilitates reliable removal of contaminants, providing a consistent and safe product regardless of application requirements.

Customizable for Diverse Applications

With adjustable plate numbers (10 to 24) and filter area flexibility (0.5 to 2 m2), this filter press accommodates both small-scale and large-volume filtration needs. The capacity, ranging from 100 to 500 liters per hour, is tailored to suit liquid sanitizer production, alcohol-based solution processing, and other disinfectant filtration tasks.

Engineered for Hygiene and Easy Operation

Sanitary tri-clamp fittings, food-grade EPDM/silicone gaskets, and a mirror or matte surface finish assure hygienic, leak-proof performance. Designed for effortless mobility with castor wheels, the machine streamlines cleaning and maintenance, making it ideal for quick rearrangements within GMP-certified pharmaceutical spaces.

FAQ's of Sanitizer Filter Press:

Q: How does the Sanitizer Filter Press ensure high filtration accuracy?

A: The filter press utilizes precision-engineered plate and frame technology with filter media capable of removing particles down to 5 microns, guaranteeing a consistently clarified end product suitable for medical and industrial applications.Q: What types of liquids can be processed with this filter press?

A: It is designed to filter and clarify liquid sanitizers, alcohol-based solutions, and disinfectant liquids, supporting various industrial, pharmaceutical, and hygiene-critical environments.Q: When is it recommended to choose between mirror or matte surface finishes?

A: A mirror finish is ideal for environments demanding high hygiene standards and easy cleaning, while matte finishes can be selected where glare reduction and aesthetic preferences are prioritized.Q: Where should the Sanitizer Filter Press be installed for optimal performance?

A: Install the unit in clean, GMP-compliant workspaces with access to a stable power supply (220-240V), ensuring adequate space for movement due to its castor-wheeled mobility and ease of relocation.Q: What is the process for operating the filter press?

A: Simply connect inlet and outlet hoses using the sanitary tri-clamp fittings, set the required feed pressure (2-4 kg/cm2), and initiate filtration. Its semi-automatic electric drive system ensures smooth performance, with minimal intervention needed.Q: How does the sanitizer filter press benefit manufacturers?

A: Manufacturers benefit from customizable capacity, straightforward operation, GMP/pharmaceutical compliance, reliable leak-proof performance, and corrosion-resistant construction, supporting efficient and safe sanitizer production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Processing Plants Category

Lacquer Polish Making Machine

Feature : Other, Low Maintenance, Corrosion Resistant

Power : 7.510 Hp

Motor : Other, Heavy Duty Electric Motor

Mixer Type : Other, Stirrer/Mixer Blender

Automatic : Yes

Product Type : Polish Making Machine

WATER PROOFING CHEMICAL PLANT

Feature : Other, Corrosion resistant, High efficiency, Easy operation

Power : 1530 kW

Motor : Other, Standard Industrial Motor

Mixer Type : Other, High Speed Mixer

Automatic : Yes

Product Type : Water Proofing Chemical Plant

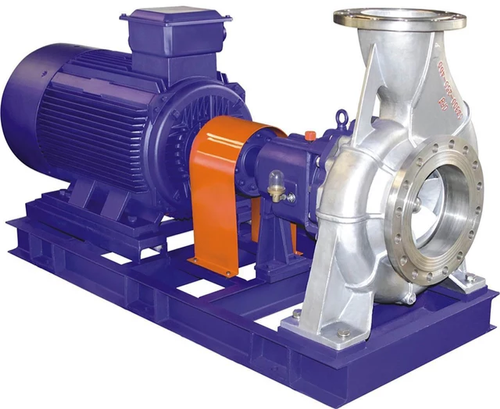

Chemical Re-circulation Process Pump

Feature : Other, Corrosion Resistant, Leak Proof, Low Maintenance

Power : Up to 15 HP

Motor : Other, 3 Phase, TEFC / Flameproof

Mixer Type : Other, Single Stage

Automatic : Other, SemiAutomatic

Product Type : Chemical Process Pump

Sanitizer Making Machine

Feature : Other, Corrosion Resistant, Easy Operation, High Mixing Efficiency

Power : 3 kW

Motor : Other, Heavy Duty Motor

Mixer Type : Other, Agitator Mixer

Automatic : Yes

Product Type : Sanitizer Making Machine

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry