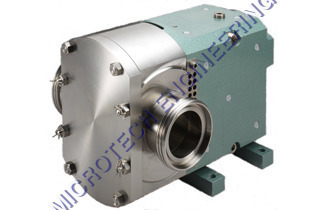

Honey Transfer Pump

Honey Transfer Pump Specification

- Max Suction

- 5 meters

- Features

- Corrosion resistant, Easy cleaning, Low maintenance

- Control System

- Manual

- Flow Rate

- 30-40 L/min

- Noise Level

- Low

- Theory

- Rotary Pump

- Voltage

- 220-240V

- Working Temperature

- up to 60C

- Frequency

- 50 Hz

- Head Size

- 18 meters

- Discharge Pressure

- 1.8 bar

- Mounting Type

- Portable / Base Mounted

- Caliber

- 25 mm

- Speed

- 2800 RPM

- Inlet/Outlet

- 25 mm / 25 mm

- Material

- Stainless Steel

- Structure

- Gear Pump

- Power

- 0.75 kW

- Standard

- ISO Certified

- Fuel Type

- Electric

- Pressure

- 1.8 bar

- Usage

- Honey Transfer

- Application

- Food Industry, Honey Processing

- Suction Type

- Positive Displacement

- Seals Type

- Mechanical Seal

- Priming

- Self-priming

- Pump Type

- Lobe/Rotor

- Capacity

- 40 Liter/Min

- Motor Protection

- IP55

- Weight

- 23 kg

- Body Finish

- Mirror Polished

- Input Power

- Single Phase

- Dimensions (LxWxH)

- 410 x 260 x 330 mm

- Suitable Viscosity

- Up to 5000 cP

- Connection Type

- Threaded

Honey Transfer Pump Trade Information

- Minimum Order Quantity

- 01 Piece

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Pieces Per Year

- Delivery Time

- 100 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- WOODEN CHARGE

- Main Export Market(s)

- Middle East, Africa, Central America, Eastern Europe, South America, Western Europe, Asia, North America, Australia

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2008 MSME

About Honey Transfer Pump

Honey Transfer Pump MICROTECH ENGINEERING Lobe pumps are used in a variety of industries including, pulp and paper, chemical, food, beverage, Pharmaceutical, and biotechnology. They are popular in these Diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics.These pumps offer a variety of lobe options including single, biwing, tri-lobe (shown), and multi-lobe.Rotary lobe pumps are Non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self- priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous.

Application

Alcohol - Apple pur Apricots - Baby food Batter Beans Beer Beetroot - Biscuit Cream Blackcurrants Brine Broth -Butter fat Caramel - Castor Oil - Cat food - Cheese curd - Cheese whey Cherries - Chicken paste - Chili con Carne Chocolate Chutney Cockles - Coconut oil - Cod oil Coffee liquor Cordials -Corn oil - Corn syrup Cottage cheese - Cotton seed oil Cranberry -juice - Cream Cream cheese Custard - Dog food Dough Eggs whole - Egg yolk Essences Evaporated milk -Fish- Iodine - ointment etc

Superior Hygienic Design

With a mirror-polished stainless steel finish and mechanical seals, this pump meets the strictest food industry requirements. Its corrosion-resistant materials and easy-to-clean surfaces ensure safety and hygiene during honey processing, providing peace of mind for manufacturers and exporters.

Efficient and Versatile Operation

Thanks to its positive displacement, self-priming technology, and reliable rotary gear mechanism, the pump handles viscosities up to 5000 cP. It delivers a consistent flow rate of 30-40 L/min, making it perfect for honey transfer operations where both speed and gentleness are paramount.

Flexible Installation and Usage

Compact dimensions and portable mounting options mean this pump adapts effortlessly to a range of setups in honey processing facilities. With threaded connections (25 mm inlet/outlet) and support for manual control, its suitable for both mobile and base-mounted applications across India.

FAQs of Honey Transfer Pump:

Q: How does the honey transfer pump ensure hygienic processing?

A: The pump features a mirror-polished stainless steel body and mechanical seals, making it easy to clean and resistant to corrosion, thereby maintaining high sanitary standards essential for food-grade applications like honey handling.Q: What types of honey viscosities can this pump handle?

A: This pump is designed to transfer honey with viscosities up to 5000 centipoise (cP), accommodating a broad range of honey types and ensuring smooth operation in various food industry scenarios.Q: When is it ideal to use a self-priming honey transfer pump?

A: The pumps self-priming function is particularly useful at the start of production cycles or when the pipeline may not be initially filled with honey, reducing downtime and streamlining the transfer process.Q: Where can this pump be installed within a facility?

A: With its compact size, portable or base-mounted options, and threaded connections, the pump can be installed on processing lines, near storage tanks, or in mobile transfer setups throughout honey production sites.Q: What are the benefits of the IP55 motor protection and mechanical seals?

A: The IP55 rating protects the motor from dust and water ingress, enhancing durability, while mechanical seals provide leak resistance, ensuring reliability and extending the service life of the pump.Q: How does the pumps positive displacement design benefit honey transfer?

A: Positive displacement technology ensures a steady, pulsation-free flow, safeguarding the integrity of the honey without excess foaming or agitationcrucial for preserving honey quality during transfer.Q: What makes this pump suitable for dealers, suppliers, and food processors across India?

A: Its ISO certification, versatile application (portable or stationary), robust stainless steel construction, low maintenance requirements, and compatibility with standard Indian power supplies make it highly suitable for a broad range of clients and installations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lobe Pump Category

Shampoo transfer pump manufacturers in india

Price 25000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Seals Type : mechanical seal

Structure : Gear Pump

Max Suction : 150mm

Fuel Type : Diesel

Tooth Paste Transfer Pump

Minimum Order Quantity : 01 Piece

Seals Type : Mechanical Seal

Structure : Other, Single Stage

Max Suction : 6 m

Fuel Type : Other, Electric

Positive Rotary Lobe Pumps

Minimum Order Quantity : 01

Seals Type : Mechanical Seal / Lip Seal

Structure : Other, Horizontal

Max Suction : 7 Mtr (SelfPriming)

Fuel Type : Other, Electric

YEAST TRANSFER PUMP

Price 65098.00 INR / Unit

Minimum Order Quantity : 1 Unit

Seals Type : mechanical seal

Structure : Gear Pump

Max Suction : 150mm

Fuel Type : Gasoline

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry