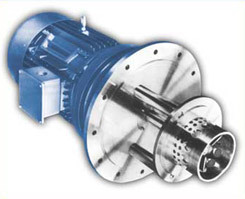

Bottom Entry Shear Mixer

Price 65087.00 INR/ Unit

Bottom Entry Shear Mixer Specification

- Type

- Other

- Material

- STAINLESS STEEL

- Capacity

- 100 Kg/hr

- Computerized

- Yes

- Control Mode

- Automatic

- Voltage

- 410 Volt (v)

- Power

- 100 Horsepower (HP)

- Weight (kg)

- 80 Kilograms (kg)

- Dimension (L*W*H)

- 100*100*150 Centimeter (cm)

- Color

- ELECTRO POLISH

- Warranty

- 12 MONTHS

Bottom Entry Shear Mixer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cheque, Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Paypal, Western Union, Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100 Units Per Year

- Delivery Time

- 100 Years

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- WOODEN BOX

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2015 MSME

About Bottom Entry Shear Mixer

Bottom Entry Shear Mixer

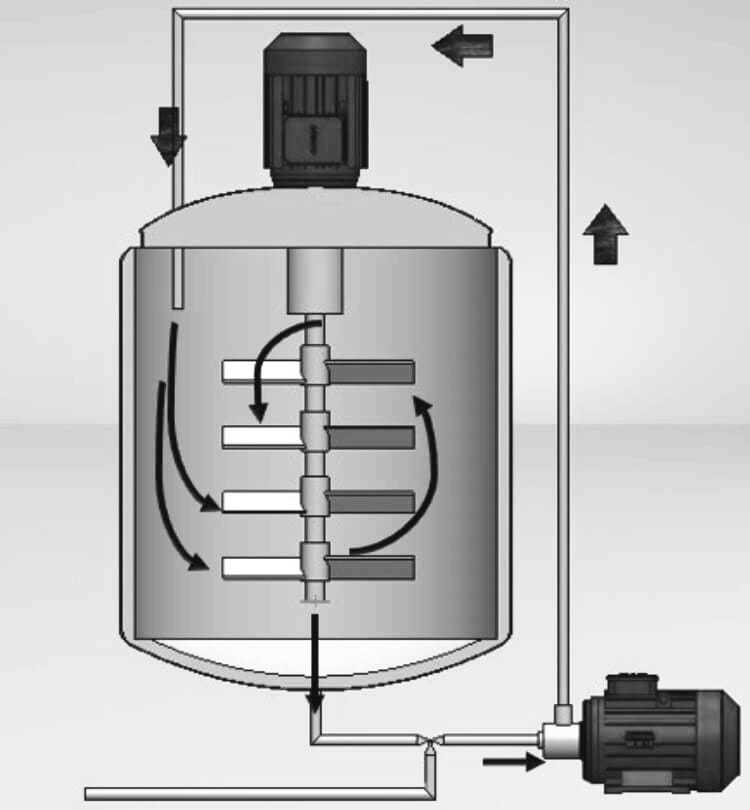

Microtech Engineering Bottom Entry Mixers Are Typically Used In Conjunction With A Stirrer/Scraper Unit. It Emulsifies, Homogenizes, Solubilizes, Suspends, Disperses And Disintegrates Solids. The Bottom Gives High Shear Homogenization While The Stirrer/ Scraper Distribute The Homogenized Output Uniformly Throughout The Vessel. This Is Ideal For High-Viscosity Cosmetic, Pharmaceutical And Food Products. They Can Also Be Used On Low Viscosity Products To Wet Our Powders. Clean-In-Place Design With A Simple, Easy To Clean Construction.

Aeration Free

- Self-Pumping

- No Bypassing

- Interchangeable Warheads

- Sanitary Construction

- Easy Maintenance

- Lower Power Requirements

- Reduces Particle Size

- Rapidly Dissolves Solids

Accelerates Reactions

Sealing: Single Mechanical Shaft Sealing: A Single Carbon/Ceramic Mechanical Shaft Seal With Viton Elastomers Is Standard. Other Face Materials And Elastomers Are Available As Optional Extras. Double Mechanical Shaft Sealing: These Are Required When Processing Products That Are Abrasive, Sticky Or Viscous Or When The System Is Under Vacuum. Sealant Flushing Systems Can Be Supplied As Optional Extras.

Operating Pressures: All Standard Models Are Designed For Operation On Pressures Not In Excess Of 40 Psig (2.8 Bar). High-Pressure Units Are Available Upon Request.

Materials Of Construction: All Wetted Parts Are In 304/316 304l/316l Stainless Steel. Special Materials On Request. Electropolished Finish Is Available As An Optional Extra.

Cleaning: Clean-In-Place (CIP) Design. Simple, Easy To Clean Construction.

Motor Specifications: Tefc, Washdown Duty And Explosion Proof Motors Are Available As Standard. Inverter Rated, Stainless Steel And Other Motors Are Available As Optional Extras.

Mounting: Stainless Steel Flange Fitting Is Available As Standard. Clamp-On Fitting Is Optional For Smaller Machines.

Operating Pressures: All Standard Models Are Designed For Operation On Pressures Not In Excess Of 40 Psig (2.8 Bar). High-Pressure Units Are Available Upon Request.

Ultra Sanitary: Model Available With Features Including:

Crevice-Free Construction

Sanitary Metal Bellows Shaft Seal

Electropolished Finish

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

High Pressure Triplex Pumps

Material : Stainless Steel / Mild Steel

Voltage : 220440V (As per Model)

Control Mode : Other, Manual/Automatic

Computerized : No

Vacuum Paddle Mixer Dryer

Material : Stainless Steel (SS304/SS316)

Voltage : 220440 V

Control Mode : Other, Automatic / SemiAutomatic

Computerized : No

Semi Automatic Liquid Filling Machines

Material : Stainless Steel

Voltage : 220V AC

Control Mode : Other, Pneumatic / Manual

Computerized : No

Batch solid-liquid mixing system

Material : Stainless Steel (SS 304/316)

Voltage : 220V/380V/415V, 50/60Hz

Control Mode : Other, Automatic / Semiautomatic

Computerized : Other, Yes, with PLC touch screen interface

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry