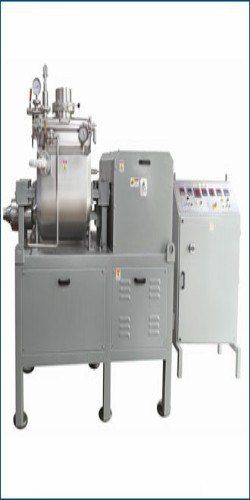

Batch solid-liquid mixing system

Batch solid-liquid mixing system Specification

- Features

- Hygienic design, CIP/SIP compatible, High-shear mixing, Easy operation, Low maintenance

- Frequency

- 50/60 Hz

- Phase

- Single or Three Phase

- Noise Level

- < 70 dB

- Temperature

- Ambient to 140C (dependent on heating system)

- Usage & Applications

- Pharmaceuticals, Food & Beverages, Chemicals, Cosmetics, Dairy

- Type

- Batch Solid-Liquid Mixing System

- Material

- Stainless Steel (SS 304/316)

- Capacity

- 5010000 Liters (customizable)

- Computerized

- Yes, with PLC touch screen interface

- Control Mode

- Automatic / Semi-automatic

- Voltage

- 220V/380V/415V, 50/60Hz

- Power

- 2 kW 30 kW (as per model)

- Weight (kg)

- 600 3000 kg, depends on capacity

- Dimension (L*W*H)

- Custom as per design/capacity

- Color

- Metallic / Matte finish

- Pressure Rating

- Atmospheric or Pressurized as needed

- Agitator Type

- High-shear, Paddle, or Anchor as per requirement

- Motor Brand

- Siemens/ABB or equivalent

- Sealing

- Mechanical Seal for leakage prevention

- Inlet/Outlet Size

- Customizable

- Heating/Cooling Jacket

- Available (Steam or Electric) on request

- Cleaning

- CIP (Clean-in-place) ready design

- Level Sensor

- Yes (optional)

- Mixing Speed

- Variable speed control, up to 1500 rpm

- Safety Features

- Emergency stop, overload protection, interlocking system

- Discharge Valve

- Sanitary bottom outlet, butterfly/ball valve

Batch solid-liquid mixing system Trade Information

- FOB Port

- yes

- Payment Terms

- Paypal, Letter of Credit (L/C), Western Union, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, North America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Batch solid-liquid mixing system

ApplicationFood: jam, ice cream, milk drink, baby food, etc.Cosmetics: toothpaste, shampoo, hand cream, natural skin care products, etc.Pharmacy: syrup, nutrient solution, pectin liquid, meidcine coating, etc.Chemicals: fertilizer, fiber, cleaner artifical resin, etc.Paint /coating: emulsion paint, water based paint, dispersible paint, offset ink, textile pigment, etc.Versatile Mixing Solutions for Multiple Industries

Designed to accommodate a range of batch sizes, from 50 to 10,000 liters, this mixing system offers reliability and efficiency for industries such as food & beverages, pharmaceuticals, chemicals, cosmetics, and dairy. Customizable inlet/outlet sizes and various agitator types ensure optimal mixing performance tailored to specific application requirements.

Superior Hygiene and Safety Features

Manufactured using high-grade stainless steel (SS 304/316), the mixer supports CIP (Clean-in-place) compatibility and includes a sanitary outlet, mechanical seal for leakage prevention, and noise control (< 70 dB). Safety is enhanced by emergency stop, overload protection, and interlocking systems, ensuring secure and problem-free operation.

FAQ's of Batch solid-liquid mixing system:

Q: How is the mixing speed controlled in this batch solid-liquid mixing system?

A: Mixing speed is adjustable with variable speed control, enabling speeds up to 1500 rpm as per process requirements. Operators can easily set and monitor the speed via the PLC touch screen interface, ensuring precise homogenization for different recipes.Q: What types of agitators are available for this mixing system?

A: Depending on the mixing needs, high-shear, paddle, or anchor agitator configurations can be chosen. This flexibility caters to various viscosities and product types, enabling efficient and thorough solid-liquid mixing.Q: When is the heating or cooling jacket recommended, and how does it function?

A: A heating or cooling jacket is available on request and is recommended when temperature control is critical for product quality or consistency. Jackets operate using steam or electric sources, maintaining processing temperatures from ambient up to 140C.Q: Where can this mixing system be installed and used?

A: The system is suitable for pharmaceutical laboratories, food & beverage processing plants, chemical manufacturers, cosmetic producers, and dairy facilities across India. Its design supports easy installation and integration into new or existing setups.Q: What is the cleaning process for the batch solid-liquid mixing system?

A: Cleaning is simplified with a CIP-ready (Clean-in-Place) design, allowing automated in-place cleaning that ensures thorough sanitization of all internal surfaces without the need for disassembly.Q: How does the system ensure product safety and operator protection?

A: Product and operator safety are prioritized through features like a secure sanitary bottom outlet, mechanical seals to prevent leaks, emergency stop button, overload protection, and an interlocking safety system.Q: What are the main benefits of using this batch mixing system?

A: Key advantages include efficient high-shear mixing, easy operation via PLC interface, hygienic design suited for sensitive products, low maintenance requirements, customizable capacities, and robust safety and automation features for continuous reliable performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

Sigma Mixer With Extruder Screw

Type : Other, Sigma Mixer With Extruder Screw

Frequency : 50 Hz

Features : Heavyduty construction, twin sigma blades, integrated extruder screw, easy discharge, jacketed vessel for heating/cooling

Computerized : No

Capacity : 50 Liter to 5000 Liter

Phase : Three Phase

Homeopathic Liquid Medicine Making Machine

Type : Other, Homeopathic Liquid Medicine Making Machine

Frequency : 5060 Hz

Features : Corrosion resistance, High efficiency, Easy to clean, GMP compliant, Low maintenance

Computerized : Yes

Capacity : 100200 Liters/hour

Phase : Single/Three Phase

Continuous Mixer Blender System: Simplex Mixer

Type : Other, Continuous Mixer Blender System

Frequency : 50/60 Hz

Features : Continuous operation, Uniform blending, Adjustable speed, Energy efficient, Easy cleaning and maintenance, Robust construction

Computerized : No

Capacity : 100 to 5000 kg/hr (customized)

Phase : Three Phase

High Pressure Triplex Pumps

Type : Other, High Pressure Triplex Pump

Frequency : 50/60 Hz

Features : Corrosionresistant body, Heavyduty construction, Low maintenance, Reliable performance

Computerized : No

Capacity : Flow Rate: 5 to 80 LPM (Liters per Minute), Pressure: Up to 500 Bar

Phase : Single Phase / Three Phase

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry