Call: 08071931448

Barrel Mixing & Emptying Pump

Barrel Mixing & Emptying Pump Specification

- Theory

- Rotary pump with integrated mixing

- Frequency

- 50 Hz

- Head Size

- Maximum 15 m

- Caliber

- 40 mm barrel dia.

- Flow Rate

- up to 70 L/min

- Mounting Type

- Barrel/top mounting

- Discharge Pressure

- Up to 2 bar

- Inlet/Outlet

- 1 BSP (inlet), 1 BSP (outlet)

- Speed

- 2800 rpm

- Fuel Tank Capacity

- N/A (Electric Pump)

- Control System

- Manual ON/OFF switch

- Working Temperature

- Up to 60C

- Features

- Integrated mixing function, corrosion resistance, portable design, easy cleaning

- Max Suction

- Up to 3 m

- Voltage

- 230 V / 50 Hz

- Noise Level

- <75 dB(A)

- Material

- SS 316 / Polypropylene (PP)

- Structure

- Barrel pump with integrated mixer

- Power

- 0.55 kW

- Standard

- Industrial grade

- Fuel Type

- Electric operated

- Pressure

- Max 2 bar

- Usage

- Barrel mixing & transferring liquids

- Application

- Chemical, Pharmaceutical, Food, Cosmetic, Paint industries

- Suction Type

- Vertical suction pipe

- Seals Type

- Mechanical seal (PTFE/EPDM)

- Priming

- Self-priming

- Pump Type

- Barrel mixing emptying pump

- Capacity

- Up to 70 liters/min

Barrel Mixing & Emptying Pump Trade Information

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Per Year

- Delivery Time

- 100 Years

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- WOODEN CHRGE

- Main Export Market(s)

- Eastern Europe, Middle East, Africa, Central America, South America, Western Europe, Asia, North America, Australia

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2008 MSME

About Barrel Mixing & Emptying Pump

Barrel Mixing & Emptying Pump

Item Code: BEP

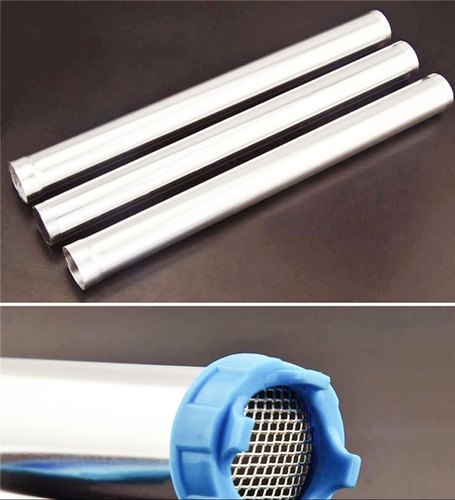

Barrel Empty Progressive Cavity Eccentric Screw Pumps /Barrel Decanting Pump, PPB Series. It is Universal Robust and Powerful High Viscosity Liquid Pump, Suitable For High Viscosity, Pasty & Low Viscosity Products From Casks And Narrow Containers.

Execution:

Item Code: BEP

- MICROTECH ENGINEERING

Barrel Empty Progressive Cavity Eccentric Screw Pumps /Barrel Decanting Pump, PPB Series. It is Universal Robust and Powerful High Viscosity Liquid Pump, Suitable For High Viscosity, Pasty & Low Viscosity Products From Casks And Narrow Containers.

Execution:

- Long life, Flexi shaft and closed or open Cardan Joints.

- Quick to dismantle, convenient to clean

- Barrel in AISI 304, AISI 316 & AISI 316L.

- Rotor / Shaft & Rotating Parts in AISI 304, AISI 316 & AISI 316L

- Torsion Free Moulded to Stainless Steel Tube Rubber Stator in Nitrile, Hyplon, FPM, NCR Food Grade Nitrile, EPDM in white & black colour elastomers. Shaft Sealing by Stuffing Box Gland Packed / Mechanical Seal

- Drinking Water schemes

- Water Pressure Systems

- Irrigation System

- Industrial Use

- Stock Watering

Specifications:

Capacity

Up to 7 m/hr.

Pressure Stages

Up to 8 Bar

Temperature

Up to 150 C / 302 F

Viscosity

Up to 25000 cP

Solid Handling Capability

Up to 12%

Pump Barrel Diameter

42, 51, 60 mm.

Immersion Length

450, 700, 1000, 1200 mm.

Specifications:

Capacity | Up to 7 m/hr. |

Pressure Stages | Up to 8 Bar |

Temperature | Up to 150 C / 302 F |

Viscosity | Up to 25000 cP |

Solid Handling Capability | Up to 12% |

Pump Barrel Diameter | 42, 51, 60 mm. |

Immersion Length | 450, 700, 1000, 1200 mm. |

Robust Construction and Corrosion Resistance

Engineered from high-grade stainless steel (SS 316) or polypropylene, the pump guarantees excellent chemical resistance and durable operation even in demanding industrial environments. The modular design allows for easy cleaning and maintenance, supporting stringent hygiene standards for food, pharmaceutical, and cosmetic industries.

Advanced Mixing and Transfer Functionality

This pump integrates a mixing shaft and variable mixing nozzles, enabling simultaneous homogenization and efficient emptying of barrels. The vertical suction pipe ensures thorough liquid agitation and seamless transfer, reducing material wastage and improving workflow flexibility in industrial settings.

Safety and Compliance Standards

Equipped with an IP55 motor enclosure and CE marking, the pump ensures safe operation against dust and water ingress. The manual ON/OFF switch, mechanical seals (PTFE/EPDM), and industrial-grade structure offer reliable performance and adherence to international safety standards.

FAQs of Barrel Mixing & Emptying Pump:

Q: How does the Barrel Mixing & Emptying Pump operate to mix and transfer liquids simultaneously?

A: The pump uses a rotary mechanism with an integrated mixing shaft and vertical suction pipe to agitate and transfer liquids in a single operation. Variable mixing nozzles enable thorough homogenization, making it highly efficient for both mixing and emptying barrels.Q: What types of liquids can this pump handle, and what are its viscosity and temperature limits?

A: This pump is suitable for a wide range of fluids, including chemicals, pharmaceuticals, food, cosmetics, and paints. It can handle viscosities up to 1000 mPas and working temperatures up to 60C, with corrosion-resistant materials ensuring compatibility with aggressive liquids.Q: When should I choose custom immersion tube lengths, and how do I specify them?

A: Custom immersion tube lengths are recommended when your barrel or container depth exceeds the 1000 mm standard or if specific installation requirements exist. To order, provide exact depth measurements and any special mounting preferences to your supplier or manufacturer.Q: Where is this pump best installed and what mounting types are available?

A: The pump is designed for barrel or top mounting on containers commonly used in industrial settings. Its portable structure with a 3 m cable allows flexible placement and easy relocation within chemical plants, pharmaceutical operations, food processing units, or paint factories.Q: What is the process for cleaning and maintaining the pump after use?

A: The pump features a modular and easy-to-clean design. After use, flush the system with compatible cleaning fluids, disconnect the mixing shaft if necessary, and inspect seals and hoses for wear. Regular cleaning not only ensures hygiene but also prolongs pump life.Q: How does the integrated mixing function benefit industrial users?

A: Integrated mixing significantly reduces process time by combining agitation and transfer in a single step. This improves product consistency, prevents sedimentation, and minimizes operational downtime, which is especially valuable for high-throughput industries.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry