Call: 08071931448

Barrel Emptying Pump

Barrel Emptying Pump Specification

- Head Size

- 10 meters

- Mounting Type

- Portable

- Caliber

- 25 mm

- Noise Level

- < 70 dB(A)

- Control System

- Manual

- Voltage

- 220-240V

- Inlet/Outlet

- 1 / 1

- Theory

- Centrifugal Pump

- Frequency

- 50/60 Hz

- Speed

- 2800 rpm

- Working Temperature

- 0 50C

- Discharge Pressure

- 1.0 bar

- Max Suction

- 3 meters

- Flow Rate

- 60 L/min

- Features

- Corrosion Resistant, Lightweight, Easy to Clean

- Material

- Stainless Steel / PP

- Structure

- Barrel Pump

- Power

- 0.55 kW

- Standard

- ISO 5199

- Fuel Type

- Electric

- Pressure

- 1.0 bar

- Usage

- Industrial Barrel Emptying

- Application

- Chemical, Food, Pharma, Oil

- Suction Type

- Vertical

- Seals Type

- Mechanical Seal

- Priming

- Self-priming

- Pump Type

- Electric Barrel Emptying Pump

- Capacity

- 60 L/min

Barrel Emptying Pump Trade Information

- Payment Terms

- Cheque, Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- Supply Ability

- 100 Per Year

- Delivery Time

- 100 Years

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- WOODEN CHARGE

- Main Export Market(s)

- North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, Australia

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2008 MSME

About Barrel Emptying Pump

Barrel Emptying Pump

Item Code: BEP

MICROTECH ENGINEERING

Barrel Empty Progressive Cavity Eccentric Screw Pumps /Barrel Decanting Pump, PPB Series. It is Universal Robust and Powerful High Viscosity Liquid Pump, Suitable For High Viscosity, Pasty & Low Viscosity Products From Casks And Narrow Containers.

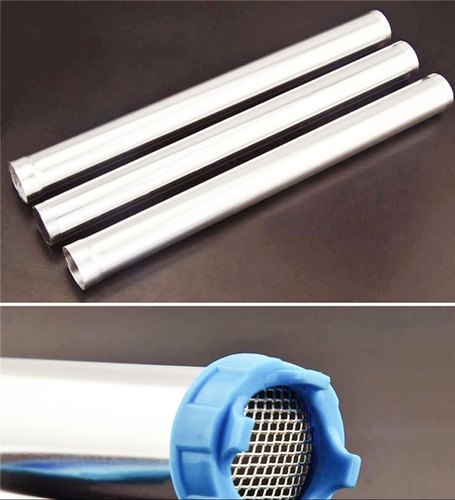

Execution:

- Long life, Flexi shaft and closed or open Cardan Joints.

- Quick to dismantle, convenient to clean

- Barrel in AISI 304, AISI 316 & AISI 316L.

- Rotor / Shaft & Rotating Parts in AISI 304, AISI 316 & AISI 316L

- Torsion Free Moulded to Stainless Steel Tube Rubber Stator in Nitrile, Hyplon, FPM, NCR Food Grade Nitrile, EPDM in white & black colour elastomers.

- Shaft Sealing by Stuffing Box Gland Packed / Mechanical Seal

Applications:

- Drinking Water schemes

- Water Pressure Systems

- Irrigation System

- Industrial Use

- Stock Watering

Specifications:

- Capacity Up to 7 m³/hr.

- Pressure Stages Up to 8 Bar

- Temperature Up to 150° C / 302° F

- Viscosity Up to 25000 cP

- Solid Handling Capability Up to 12%

- Pump Barrel Diameter 42, 51, 60 mm.

- Immersion Length 450, 700, 1000, 1200 mm.

Superior Material Quality & Corrosion Resistance

Built with high-grade stainless steel and polypropylene, this pump stands out for its exceptional corrosion resistance, making it ideal for harsh chemical environments. The mechanical seal offers added protection against leaks, while the lightweight structure ensures ease in handling and maintenance.

Efficient Performance & Versatility

Operating at a speed of 2800 rpm, the pump delivers a consistent capacity of 60 L/min and a discharge pressure of 1.0 bar. Its self-priming and vertical suction design guarantee optimal performance in emptying 200L barrels containing chemical, food, pharmaceutical, or oil products.

User-Friendly Operation & Maintenance

The ergonomic handle and portable mounting facilitate easy setup and transport. With ISO 5199 compliance and available replacement parts, users benefit from dependable operation and straightforward maintenance. The pumps noise level is kept below 70 dB(A) for comfortable industrial use.

FAQs of Barrel Emptying Pump:

Q: How do I install and use the Barrel Emptying Pump with a 200L drum?

A: To install, securely mount the pump on the drum using its ergonomic handle and ensure the inlet fits the 25 mm caliber. Connect the single-phase motor to a 220-240V electric supply, and verify the pump is operated within the 0 50C temperature range. Manual control allows straightforward activation and monitoring during the transfer process.Q: What types of fluids can this pump handle efficiently?

A: This pump is designed for fluids with viscosities up to 800 cps, making it suitable for a wide range of chemicals, food products, pharmaceuticals, and oils. Its corrosion-resistant build ensures safe transfer of aggressive or sensitive materials without contamination.Q: When should replacement parts be considered for this pump?

A: Replacement parts should be considered when you observe decreased performance, wear on mechanical seals, or difficulty in self-priming. Regular maintenance and visual inspections ensure long-term reliability and efficiency of the pump.Q: Where can the Barrel Emptying Pump be used in India?

A: The pump is suitable for mounting in any facility handling 200L drums, such as chemical plants, food processing units, pharmaceutical manufacturing, and oil distribution centers. Its portability also allows easy relocation between workstations as needed.Q: What is the process for cleaning and maintaining this pump?

A: After use, disconnect the power and flush the pump with a suitable cleaning medium. The smooth stainless steel and polypropylene surfaces are easy to clean. Inspect the mechanical seal and impeller regularly, and replace parts if necessary to maintain optimal performance.Q: How does the pumps protection class IP55 benefit industrial users?

A: The IP55 protection class safeguards the motor and electrical components against dust ingress and low-pressure water jets, ensuring reliable operation in challenging industrial environments and prolonging service life.Q: What are the main benefits of using this barrel emptying pump?

A: Key benefits include efficient handling of viscous fluids, corrosion resistance, lightweight portability, user-friendly operation, low noise levels, and compliance with ISO standardsmaking it a dependable choice for demanding industrial use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry