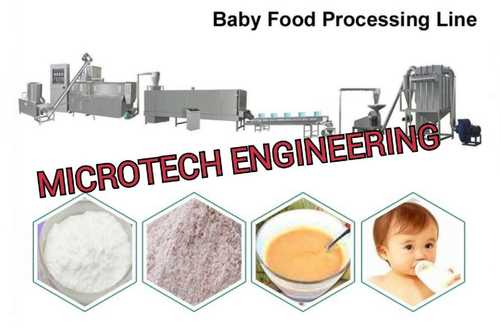

Baby food processing machine

MOQ : 1 Unit

Baby food processing machine Specification

- Heating Method

- Electric Heating

- Feeding System

- Automatic Feeding Hopper

- Automation Grade

- Automatic

- Noise Level

- Low (<70 dB)

- Speed Mode

- Variable Speed

- Machine Type

- Continuous Processing

- Operating Temperature

- 30C - 120C

- Features

- Energy Efficient, User-Friendly Interface, Safety Interlocks

- Frequency

- 50 Hz

- Phase

- Three Phase

- Power Source

- Electric

- Function Type

- Mixing, Cooking, Homogenizing, Pasteurizing

- Product Type

- Food Processing Machinery

- General Use

- Industrial Baby Food Production

- Material

- Stainless Steel

- Type

- Baby Food Processing Machine

- Capacity

- 100-500 kg/h

- Weight (kg)

- 2800 kg

- Product Shape

- Rectangular Base with Cylindrical Processing Chambers

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC (Programmable Logic Controller)

- Installation Type

- Floor-mounted

- Voltage

- 380 V

- Power

- 35 kW

- Dimension (L*W*H)

- 4000 x 1500 x 2200 mm

- Raw Material

- Grains, Milk, Vegetables, Fruits

- Feature

- High Production Efficiency, Easy Cleaning, Hygienic Processing

- Color

- Stainless Steel Silver

- Output Product Form

- Powder or Paste

- Sanitization Method

- CIP (Clean-In-Place) System

- Transportability

- Integrated Heavy Duty Wheels

- Safety Features

- Emergency Stop, Overload Protection

- Cooling Method

- Water Cooled Jackets

- Production Line Capability

- Can be integrated with Packing Machines

- Application

- Baby Cereal, Puree, Formula

- Maintenance

- Low Maintenance Design

- Material Thickness

- 3 mm (Contact Parts)

Baby food processing machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- INDIA

- Payment Terms

- Paypal, Western Union, Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 2 Week

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- WOODEN BOX

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015 MEMS

About Baby food processing machine

The highlighted Baby Food Processing Machine is highly recommended for its rare combination of excellent design, soaring production efficiency, and advanced hygiene standards. Crafted from stainless steel with 3 mm contact parts, this sought-after machine delivers exceptional performance for cereals, purees, and formulas. Featuring an automatic PLC control system, variable speed modes, and low maintenance needs, it integrates seamlessly with packing machines. Safety is ensured through overload protection and emergency stops, while heavy-duty transport wheels enhance mobility. This industrial solution supports output as powder or paste, ensuring hygienic and energy-efficient operations.

Specific Applications and Versatility of Baby Food Processing Machine

The baby food processing machine, with a rectangular base and cylindrical chambers, is purpose-built for both specific and general industrial uses. Its surface of application includes mixing, cooking, pasteurizing, and homogenizing baby cereal, puree, and formula products. Developed for manufacturers, distributors, and suppliers, this machine supports the hygienic production of goods from a range of raw materials-grains, vegetables, fruits, and milk-ensuring the highest standards are met for consumer safety and nutrition.

Payment Terms, Export Markets, and Packaging Details

Our baby food processing machine is available for delivery with flexible payment terms to suit your proposal amount, ensuring a smooth purchase experience. Main export markets include India and international locations, supported by robust transport solutions for reliable drop-off. Each machine is packaged with high-grade protective materials to ensure safe transportation. We cater to a wide range of partners-dealers, wholesalers, traders, and retailers-facilitating global reach and seamless distribution.

Specific Applications and Versatility of Baby Food Processing Machine

The baby food processing machine, with a rectangular base and cylindrical chambers, is purpose-built for both specific and general industrial uses. Its surface of application includes mixing, cooking, pasteurizing, and homogenizing baby cereal, puree, and formula products. Developed for manufacturers, distributors, and suppliers, this machine supports the hygienic production of goods from a range of raw materials-grains, vegetables, fruits, and milk-ensuring the highest standards are met for consumer safety and nutrition.

Payment Terms, Export Markets, and Packaging Details

Our baby food processing machine is available for delivery with flexible payment terms to suit your proposal amount, ensuring a smooth purchase experience. Main export markets include India and international locations, supported by robust transport solutions for reliable drop-off. Each machine is packaged with high-grade protective materials to ensure safe transportation. We cater to a wide range of partners-dealers, wholesalers, traders, and retailers-facilitating global reach and seamless distribution.

FAQ's of Baby food processing machine:

Q: How does the CIP sanitization system benefit the cleaning process?

A: The Clean-In-Place (CIP) system allows for thorough internal cleaning of the processing chambers without disassembly, making sanitation efficient, time-saving, and highly hygienic-particularly important for baby food production.Q: What types of baby food products can be processed with this machine?

A: This machine is designed to process a variety of baby foods, including cereal, puree, and formula, using raw materials such as grains, vegetables, fruits, and milk.Q: Where can this machine be installed, and how is it transported?

A: The machine is floor-mounted for stability and equipped with integrated heavy-duty wheels, making it easy to transport for installation or repositioning within production facilities.Q: What are the key safety features of the baby food processing machine?

A: Key safety features include emergency stop buttons, overload protection, and safety interlocks, all of which ensure operator safety and reduce the risk of accidents during operation.Q: How does the machine support continuous and energy-efficient production?

A: With automatic feeding systems, PLC controls, electric heating, and water-cooled jackets, the machine allows for continuous high-volume production, optimized for energy efficiency and minimal operator intervention.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in FOOD PROCESSING EQUIPMENT Category

Cheese spread making machine

Price 149455.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Type : Food Dryer, Food Processors, Snacks Extruder, Ball Gum Plant

Product Type : food processing machine

Automatic : Yes

Non dairy whip cream processing plant

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Type : Food Dryer, Food Processors, Snacks Extruder, Ball Gum Plant

Product Type : food processing machine

Automatic : Yes

GUMMY JELLY PROCESSING PLANT

Price 1235928 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Steel, Other

Type : Food Processors

Product Type : GUMMY JELLY PROCESSING PLANT

Automatic : No

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry