Tablet Press-TabXpress-IV

Tablet Press-TabXpress-IV Specification

- Frequency

- 50 Hz

- Phase

- 3 Phase

- Temperature

- Ambient

- Noise Level

- Low

- Features

- High Speed, Auto Lubrication, Double-Sided Tablets, Safety Interlocks

- Usage & Applications

- Pharmaceutical Tablet Compression

- Type

- Tablet Press Machine

- Material

- Stainless Steel

- Capacity

- Up to 120,000 tablets/hour

- Computerized

- Yes

- Control Mode

- PLC Controlled

- Voltage

- 415 V

- Power

- 5.5 kW

- Weight (kg)

- 850 kg

- Dimension (L*W*H)

- 1100 x 900 x 1800 mm

- Color

- Silver

- Pre-compression

- Available

- Environmental Conditions

- Clean Room

- Lubrication System

- Automatic Centralized

- Electrical Protection

- IP55

- Max Height of Tablet

- 8 mm

- Filling Depth

- Max 20 mm

- Number of Stations

- 45

- Display

- 7-inch Touch Screen Interface

- Max Compression Force

- 100 kN

- Main Drive Type

- Servo Motor

- Max Tablet Diameter

- 25 mm

- Output Hopper

- Stainless Steel

- Cooling System

- Air Cooled

- Turret Speed

- Up to 65 RPM

- Dust Extraction

- Integrated Port

- Safety System

- Emergency Stop, Overload Protection

- Sound Level

- < 75 dB

- Servo Motor

- Included for Main Drive

Tablet Press-TabXpress-IV Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Paypal, Western Union, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Asia, Central America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Tablet Press-TabXpress-IV

Tablet Press-TabXpress-IV

High Speed Double Sided with Pre-Compression Tablet Press- GMP Model

Application & Process :

Advanced Compression Technology

Utilizing a servo motor for the main drive and offering a maximum compression force of 100 kN, TabXpress-IV was designed for consistent tablet density and secure mechanical operation. It accommodates double-sided tablet production with highly adjustable filling depth and turret speed, ensuring flexibility for diverse pharmaceutical formulations.

Centralized Safety and Efficiency

The built-in emergency stop, overload protection, and automatic lubrication system enhance operational safety and device longevity. The IP55-rated electrical protection and integrated dust extraction port provide a secure and clean workspace, reducing maintenance needs and ensuring compliant manufacturing.

Intuitive Control and Output

Operators benefit from the 7-inch touch screen and PLC controller, which simplifies managing machine parameters and production data. With a stainless steel output hopper and air-cooled environment, the TabXpress-IV maintains a low sound level, streamlining tablet collection and enabling prolonged operating hours without overheating.

FAQ's of Tablet Press-TabXpress-IV:

Q: How does the TabXpress-IV Tablet Press ensure consistent tablet quality during high-speed production?

A: The TabXpress-IV features a servo-driven main drive, precise PLC controls, and a robust compression force of up to 100 kN, which collectively guarantee consistent tablet weight, hardness, and dimensions even at production rates of up to 120,000 tablets per hour.Q: What safety features are included in the TabXpress-IV for operator protection?

A: Safety is central to the TabXpress-IV's design, providing an emergency stop button, overload protection, electrical safety (IP55), safety interlocks, and an integrated dust extraction port to mitigate risks and maintain compliance in pharmaceutical environments.Q: When is the TabXpress-IV best utilized in a pharmaceutical manufacturing process?

A: TabXpress-IV is ideal for medium to large-scale pharmaceutical tablet production, particularly in clean room settings requiring high-speed output, low noise, double-sided tablet capabilities, and rigorous quality control with automated monitoring.Q: Where should the TabXpress-IV Tablet Press be installed for optimal operation?

A: The machine is intended for installation in controlled environments such as clean rooms within pharmaceutical manufacturing facilities. Its stainless steel body, IP55 protection, and integrated cooling system make it suitable for demanding conditions where hygiene and dust management are critical.Q: What benefits do computerized control and a touch screen interface offer for tablet pressing operations?

A: The PLC-controlled system and 7-inch touch screen simplify setup, parameter adjustment, and real-time operation. This reduces training time, streamlines troubleshooting, and provides immediate feedback for process optimization, resulting in enhanced productivity and quality assurance.Q: How is routine maintenance handled for the TabXpress-IV Tablet Press?

A: Maintenance is facilitated by the automatic centralized lubrication system and stainless steel construction, which minimizes wear and eases cleaning. The integrated dust extraction and overload protection help further reduce the need for frequent intervention, making routine upkeep efficient.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

Herbal Extraction Unit

Price 125873.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Color : Silver / Metallic

Control Mode : Other, Automatic / Semiautomatic

Material : Stainless Steel (SS316/SS304)

Continuous Mixer Blender System: Simplex Mixer

Computerized : No

Color : Silver / Metallic Finish

Control Mode : Other, Automatic / Semiautomatic

Material : Stainless Steel

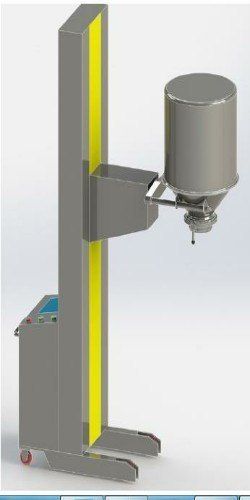

Moveable Hoist Bin Lifter

Computerized : No

Color : Blue / Yellow

Control Mode : Other, Push Button / Pendant

Material : Mild Steel

Dispohomo Reactor

Computerized : No

Color : Silver / Metallic Finish

Control Mode : Other, SemiAutomatic / Manual

Material : Stainless Steel (SS 304 / SS 316 available)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry