Herbal Extraction Unit

Price 125873.00 INR/ Unit

Herbal Extraction Unit Specification

- Phase

- Three Phase

- Noise Level

- < 75 dB

- Frequency

- 50/60 Hz

- Temperature

- Ambient to 150°C (Working temperature adjustable)

- Features

- CIP/SIP systems, Vacuum & pressure operation, Energy efficient, Explosion proof available

- Usage & Applications

- Extraction of Herbal, Botanical and Plant products for Pharmaceutical, Cosmetic, Nutraceutical industries

- Type

- Herbal Extraction Unit

- Material

- Stainless Steel (SS316/SS304)

- Capacity

- 100 L to 5000 L (Customizable)

- Computerized

- Yes

- Control Mode

- Automatic / Semi-automatic

- Voltage

- 380-415 V

- Power

- 5 to 20 kW (Depending on model)

- Weight (kg)

- 1500-7500 kg (Model dependent)

- Dimension (L*W*H)

- Custom-designed as per capacity; example: 4200*1850*2700 mm

- Color

- Silver / Metallic

- Jacketed Vessel

- Yes, for heating/cooling operation

- Safety Systems

- Pressure relief valve, Temperature controller, Emergency stop switch

- Finishing

- Mirror/Matte Polish

- Heating Mode

- Steam/Hot Water/Electrical

- Documentation

- GMP & FDA compliant operation manuals

- Customizability

- Design and accessories customizable as per client requirements

- Installation

- On-site commissioning available

- Sealing Type

- Mechanical Seal

- Extraction Process

- Solvent based (Water/Ethanol/Acetone, etc.)

- Agitator

- Variable speed agitator/mixer

Herbal Extraction Unit Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Western Union, Paypal, Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Units Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Herbal Extraction Unit

This equipment is suitable for evaporating and concentrating liquid material and recycling the organic solvent and cream in pharmaceutical, food stuff and chemical industry, etc.

This equipment mainly is consisting of concentrated tank, condenser, storage tank etc. The roundness tank is easy to clean and discharge the material.

The equipment adopts vacuum decompressed concentration and the concentration proportion can get above 1.4.

In view of the thick material, we canconfigure with mixing device as well as turnover discharging the material.

Category

Materials suitable for steam distillation etc

Flower

Rose, lavender, ylang ylang, chamomile, neroli, Geranium etc.

Plants

Rosemary, citronella, lemongrass etc.

Citrus

Lemon, orange, Bergamot, grapefruit,lime etc

Leaves

Eucalyptus leaves, Mugwort, Patchouli, Peppermint, pine needle etc.

Wood

Sandalwood, agarwood, cedarwood,Wintergreen etc.

Resin

Frankincense, myrrh etc.

Others

Cinnamon,pepper, fennel, ginger etc.

Advanced Extraction Process

This unit utilizes water, ethanol, or acetone as solvents for extracting concentrated herbal compounds. The jacketed vessel design supports consistent temperature management, allowing precise heating or cooling via steam, hot water, or electrical systems. A mechanical seal provides enhanced durability and leak prevention during operation. Variable speed agitators ensure optimal mixing for efficient extraction outcomes.

Comprehensive Safety and Control Systems

Safety is prioritized through integrated features such as a pressure relief valve, temperature controller, and emergency stop switch. The computerized and automatic/semi-automatic control options allow seamless monitoring and adjustment of extraction parameters, delivering both operational safety and process flexibility across different batch sizes.

Customizable Capacity and Installation

Available in capacities from 100 L up to 5000 L, the unit can be configured to suit your specific operational requirements, whether for small-scale trials or full-scale industrial production. Installation is handled through on-site commissioning, and the unit is designed to operate efficiently within a range of voltages, weights, and dimensions, as dictated by user needs.

FAQ's of Herbal Extraction Unit:

Q: How does the herbal extraction process work in this unit?

A: The unit performs herbal extraction using a solvent-based process, employing water, ethanol, or acetone to dissolve targeted plant compounds. The mixture is agitated at variable speeds to enhance extraction, while the jacketed vessel allows precise temperature control for optimal yield.Q: What safety systems are integrated into the unit?

A: Key safety systems include a pressure relief valve, temperature controller, and emergency stop switch. These features help prevent overheating, pressure buildup, and allow for quick shutdown in case of emergencies, ensuring safe operational environments.Q: When is the ideal usage period for commissioning the extraction unit?

A: On-site commissioning is recommended once installation is complete and utilities are in place. This ensures that the system is calibrated correctly and optimized for your specific herbal extraction requirements.Q: Where can this unit be installed and operated?

A: The herbal extraction unit is suitable for installation in pharmaceutical, cosmetic, and nutraceutical production facilities. It is designed for indoor use with appropriate space allocation as per customized dimensions and capacity.Q: What documentation and regulatory compliance does the unit offer?

A: The unit comes with GMP and FDA compliant operation manuals, facilitating adherence to international quality and safety standards throughout the extraction process.Q: How can the unit's design and capacity be tailored to specific needs?

A: Both the design and accessories of the unit are customizable. Options for vessel size, control modes, and finishing allow the system to be configured according to individual client requirements, ranging from 100 L to 5000 L.Q: What are the benefits of using this herbal extraction unit?

A: The unit delivers energy efficiency, consistent product quality, enhanced safety, and regulatory compliance. With CIP/SIP systems and vacuum/pressure operation, it supports hygienic and efficient herbal extractions, suitable for large-scale manufacturing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

Tomato Ketchup Transfer Pump

Weight (kg) : Approx. 50120 kg

Phase : Single/Three Phase

Computerized : No

Voltage : 220240 V

Material : Stainless Steel (SS 316/304)

Noise Level : Low

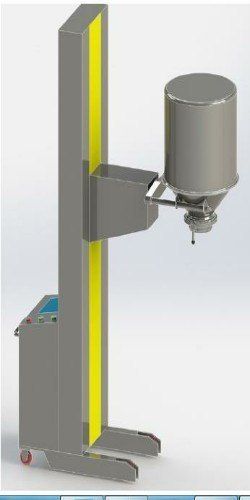

Moveable Hoist Bin Lifter

Weight (kg) : 50100 kg

Phase : Single Phase

Computerized : No

Voltage : 220240 V

Material : Mild Steel

Noise Level : <70 dB

Homeopathic Liquid Medicine Making Machine

Weight (kg) : 350 kg

Phase : Single/Three Phase

Computerized : Yes

Voltage : 220240 V

Material : Stainless Steel

Noise Level : ≤65 dB

Sigma Mixer / Kneader Mixer- Z Blade

Weight (kg) : 400 kg to 5000 kg (based on capacity)

Phase : Single / Three Phase

Computerized : No

Voltage : 220V / 380V / 415V

Material : Stainless Steel, Mild Steel

Noise Level : Low

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry