Ribbon Vacuum Mixer Dryer

Ribbon Vacuum Mixer Dryer Specification

- Frequency

- 50/60 Hz

- Phase

- Three Phase

- Noise Level

- Less than 75 dB

- Temperature

- Ambient to 150C (with vacuum)

- Features

- Efficient mixing and drying under vacuum, leak-proof seals, robust construction, energy-saving design

- Usage & Applications

- Mixing, drying and blending powders and pasty materials under vacuum conditions; used in pharmaceuticals, chemicals, food, dyestuff industries

- Type

- Ribbon Vacuum Mixer Dryer

- Material

- Stainless Steel

- Capacity

- 100 Liters to 10,000 Liters (Customized available)

- Computerized

- No

- Control Mode

- Manual/Semi-Automatic

- Voltage

- 220/380 V

- Power

- 3 kW to 22 kW (Depends on model)

- Weight (kg)

- 1200 kg (approx.; varies as per model)

- Dimension (L*W*H)

- Customized as per requirement

- Color

- Polished Steel/Grey

- Heating Media

- Hot water, steam, or thermal oil

- Operating Pressure

- Atmospheric to full vacuum

- Discharge Method

- Bottom discharge with butterfly valve or flush valve

- Drive Mechanism

- Heavy-duty geared motor

- Vacuum Level

- Up to -730 mm Hg

- Inspection Port

- Provided for sampling and cleaning

- Agitator Type

- Double Helical Ribbon

- Surface Finish

- Mirror/Matt finish (contact parts)

- Drying Method

- Indirect heating via jacketed vessel

- Safety Features

- Overload protector, emergency stop switch

- Cleaning Method

- Easy CIP/SIP arrangement

Ribbon Vacuum Mixer Dryer Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Letter of Credit (L/C), Paypal, Western Union, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, Eastern Europe, Western Europe, Middle East, Africa, Central America, South America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Ribbon Vacuum Mixer Dryer

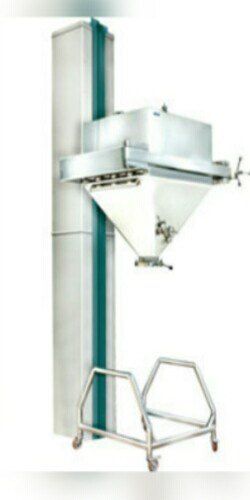

RIBBON VACUUM MIXER DRYER

Low Temperature Vacuum Mixing &Drying Process Technik

Application & Process :

The Ribbon Vacuum Mixer Dryer is suitable for mixing and drying the material which can not operate at low Temperature easily oxidized, poisonous in nature. It operates at low Temperature efficiently under vacuum. It is used for raw materials drying and mixing powder or granules of Pharmaceutical Materials, Crystalline, Insecticides, Pesticides, and Food industry and heat sensitive products.The Ribbon Vacuum Mixer Dryer consists of a jacketed cylindrical shell with rotating with specially designed Double Helical Ribbon Agitator type blade by rigid fabricated structure motor, gear box. There is provision for application of vacuum inside the shell and circulation of heating media in the jacket during the rotation of the stirrer. The large heating surface area presented by the internals of the cylindrical shell ensures uniform drying of the product, as the product gently moving while the ribbon stirrer rotates. The diffusive action induced by the mixing stirrer constantly presents a fresh layer to come into contact with the indirectly heated walls of the shell. A well designed sealing system enable maintenance of deep vacuum inside the shell, and also ensures positive circulation of a heating media in the jacket.In operation, material is filled to the top of the outer ribbon. The shaft rotates at relatively low speed and the moving ribbons push the material back and forth mixing it. The outer ribbon rotation displaces the material from the ends to the center while the inner ribbon rotations move the material from the center to the ends. This counter-current action results in homogenous blending. Mixing is achieved in 15 to 20 minutes with 90 to 95 % or better homogeneity. The bottom discharge provided for unloading of the material and easy cleaning of the mixing drum. Specially designed self adjusting sealing arrangement of unique design is provided to ensure that no black particle enters into the mixing drum.

Salient Features : Design is cGMP- Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Continuous rotation of ribbon blade, material will make continuous movement motion in the container and reach to uniform mixing and drying at low temperature.. Dust free operation. High vacuum operation Fast and uniform homogeneous mixing & draying at low temperature. Solvent recovery Continues vacuum maintain during process.. Very low value of final moisture even at low drying temperatures. . Continues vacuum maintenance during process. Vacuumized closed system with condenser, Receiver for solvent recovery & Cyclone separator to recovery the solid particle. Rapid & Complete discharge / Zero holdup after discharge Heating media can be used steam/ hot water / hot oil.

Optional Features : Option for two type designed of shell 1. Cylindrical type and 2."U" shape. Option for Flame Proof Electrical. Option for Automatic Charging Option for lump breaker. Option for condenser, Receiver & Cyclone for solvent recovery. Option for advance PLC Controls with HMI touch screen..

Safety Features : Temperature controls, Vacuum relief Valve, Over load protection and Emergency stop.Model Total Capacity - Liter Working Capacity- Liter RPM Motor Rating-HPPRVMD-5 8 3-5 PRVMD -25 40 20-25 PRVMD -50 75 25-50 PRVMD -100 150 70-100 PRVMD -200 300 150-200 PRVMD -300 450 225-300 PRVMD -550 800 400-500 PRVMD -750 1100 500-750 Pl. Contact us for more details.PRVMD -1000 1500 700-1000 PRVMD -1250 1900 950-1250 PRVMD -1500 2250 1100-1500 PRVMD -2000 3000 1500-2000 PRVMD -3000 4500 2250-3000 PRVMD -5000 7500 3750-5000

Superior Mixing and Drying Efficiency

The double helical ribbon agitator and vacuum operation guarantee thorough mixing and uniform drying, even with heat-sensitive or viscous materials. Indirect heating provides precise temperature control from ambient up to 150C, while the efficient design reduces drying time and conserves energy.

Versatile and Customizable to Your Needs

With capacities from 100 to 10,000 liters and options for surface finish, discharge type, and control modes, this mixer dryer suits diverse process demands. Whether used in pharmaceuticals, chemicals, food, or dyes, customization ensures seamless integration into your production line.

Safe, Easy Maintenance and Cleaning

Equipped with overload protection, emergency stop switch, and leak-proof seals, safety is paramount. Inspection ports support sampling and cleaning, while CIP/SIP systems facilitate quick, effective cleaning, minimizing downtime and ensuring consistent hygiene.

FAQ's of Ribbon Vacuum Mixer Dryer:

Q: How does the Ribbon Vacuum Mixer Dryer achieve efficient drying and mixing?

A: The dryer uses a double helical ribbon agitator to create a thorough mixing action, while vacuum conditions lower the boiling point of solvents, accelerating evaporation. Indirect heating through a jacketed vessel ensures even heat distribution, resulting in efficient, uniform drying with minimal product degradation.Q: What types of materials and industries can use this equipment?

A: This mixer dryer is suitable for powders and pasty materials in industries such as pharmaceuticals, chemicals, food processing, and dyestuff manufacturing. Its robust stainless steel construction and efficient mixing ability make it versatile for a wide range of formulations and applications.Q: Where is the Ribbon Vacuum Mixer Dryer typically installed?

A: It is ideal for installation in process plants, manufacturing facilities, and laboratories where controlled mixing and drying are required. Customizable sizes and configurations allow it to fit seamlessly within new or existing production workflows in both large and small-scale settings.Q: What is the cleaning process for the Ribbon Vacuum Mixer Dryer?

A: The system incorporates a CIP/SIP (Clean-in-Place/Sterilize-in-Place) arrangement, allowing rapid and thorough cleaning without major disassembly. Additionally, an inspection port and mirror/matt finish on contact parts facilitate easy sampling, visual checks, and maintenance.Q: When should you choose vacuum drying over conventional drying methods?

A: Vacuum drying is preferred when processing heat-sensitive, hygroscopic, or volatile materials, as it allows lower drying temperatures and prevents oxidation or thermal degradation. It is also advantageous when uniform, consistent drying is critical to product quality.Q: What benefits do the safety features provide operators?

A: Built-in safeguards like an overload protector and emergency stop switch help protect both operators and equipment by preventing accidents and mechanical failures. Leak-proof seals and robust construction further ensure safe operation during mixing and drying cycles.Q: How can the Ribbon Vacuum Mixer Dryer be customized to fit my process requirements?

A: You can select capacities ranging from 100 to 10,000 liters, choose between mirror or matt finish for contact surfaces, pick discharge valve types, and decide on manual or semi-automatic controls. Heating media, voltage, dimensions, and other specifications are also adaptable to your operational needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

Bin Blender

Computerized : No

Control Mode : Other, Manual / PLC Based

Color : Metallic/Silver

Voltage : 220380V

Material : Stainless Steel (SS 304/316L)

Temperature : Ambient

Vibro Sifter

Computerized : No

Control Mode : Manual

Color : Silver

Voltage : 220440 V

Material : Stainless Steel (SS304/SS316)

Temperature : Ambient

Homeopathic Liquid syrup Making Machine

Computerized : Yes

Control Mode : Other, Automatic & Manual

Color : Silver/Grey

Voltage : 220V/380V

Material : Stainless Steel (SS 316/SS 304)

Temperature : Ambient to 120C (Adjustable)

Pharmaceutical Filtration Unit

Computerized : No

Control Mode : Other, Manual / Semiautomatic

Color : Silver

Voltage : 220V / 380V

Material : Stainless Steel (SS 316L)

Temperature : Up to 80C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry