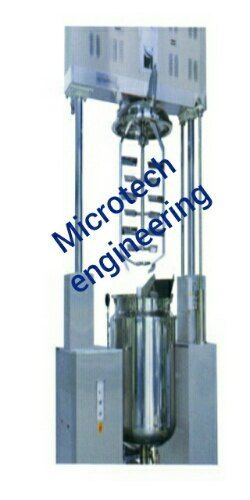

Ribbon Mixer Blender

Ribbon Mixer Blender Specification

- Usage & Applications

- Mixing Powder, Granules, Spices, Chemicals, Food, Pharmaceuticals, Feed etc.

- Phase

- 3 Phase

- Temperature

- Ambient, non-heating type

- Frequency

- 50-60 Hz

- Noise Level

- Low

- Features

- Uniform Mixing, Easy Discharge, Robust Design, Corrosion Resistant

- Type

- Ribbon Mixer Blender

- Material

- Stainless Steel

- Capacity

- 500 to 5000 Liters (customizable)

- Computerized

- No

- Control Mode

- Manual

- Voltage

- 220-440 V

- Power

- 3-15 kW (depending on model)

- Weight (kg)

- 1000-2500 kg (varies with size)

- Dimension (L*W*H)

- Custom (commonly 2500 x 1000 x 1500 mm)

- Color

- Metallic Silver

- Surface Finish

- Mirror/Matte Polished

- Mixing Time

- 10-20 minutes (batch dependent)

- Drive Type

- Gearbox Driven

- Optional Attachments

- Spray Nozzle, Heating/Cooling Jacket, Weighing System

- Installation

- Floor Mounted

- Agitator Type

- Twin Ribbon (Inner and Outer)

- Safety Features

- Overload Protection, Safety Grills

- Discharge Type

- Bottom Discharge Valve

- Cleaning

- Easy to Clean, Smooth Internal Finish

About Ribbon Mixer Blender

Ribbon Mixer Blender

Uniform Dry Mixing Process

Application & Process :

Ribbon blender mixer is used for uniformly dry mixing and blending applications in the pharmaceutical, chemical, cosmetic, food, pesticides, detergents, and plastics industries. The Ribbon Blender comprises of a U-shaped horizontal trough, specially designed Double Helical Ribbon Agitator, rigid fabricated structure motor, gear box.In operation, material is filled to the top of the outer ribbon. The shaft rotates at relatively low speed and the moving ribbons push the material back and forth mixing it. The outer ribbon rotation displaces the material from the ends to the center while the inner ribbon rotations move the material from the center to the ends. This counter-current action results in homogenous blending. Mixing is achieved in 15 to 20 minutes with 90 to 95 % or better homogeneity. The bottom discharge provided for unloading of the material and easy cleaning of the mixing drum. Specially designed self adjusting sealing arrangement of unique design is provided to ensure that no black particle enters into the mixing drum.

Salient Features :

Available in Capacity 50 kg to 5000 kg. model. Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Uniform dry maxing process. The shape of container and mixing stirrer gives sufficient continuous movement to the powder / granules result in good quality. Minor ingredients are dispersed homogeneously without the need for pre-mixing Double or triple action with blending occurring in the small voided areas immediately behind the blending ribbons. The interlocked acrylic covers of product container, enclosed drive& Overloads relay protection.

Optional Features :

Orientation of discharge is in side or centre. AC Frequency Drive with Variable speed, Jacketing for heating & Cooling, Vacuumized operation. PLC controls with HMI Touch Screen. Flame Proof Electrical.

Safety Features :

Total drive transmission system enclosed Limit switch installed in the top lid ensure lid is closed Overload relay Protection and Emergency stop button

Model Total Capacity Working Capacity RPM Motor Rating Container Dimension Over all Dimension Liters Liters Light HP MediumHP Length-mm Width-mm Height-mm Length-mm Width-mm Height-mmPRMB-5 8 3-5 PRMB-10 15 7-10 PRMB-25 40 20-25 PRMB-50 75 25-50 PRMB-100 150 70-100 PRMB-150 225 110-150 PRMB-200 300 150-200 PRMB-300 450 225-300 PRMB-400 600 300-400 PRMB-500 800 400-500 PRMB-750 1100 500-750 Please contact us for more details. PRMB-1000 1500 700-1000

Efficient Uniform Mixing

This blender utilizes a twin ribbon agitator system-both inner and outer ribbons-that thoroughly lifts, folds, and agitates your ingredients. Regardless of whether you're processing powders, granules, food seasonings, or chemicals, the result is a homogeneous blend within 10-20 minutes (dependent on batch size and content properties). The robust gearbox drive ensures consistent and reliable operation.

Superior Hygiene and Safety

Designed with industries like food and pharmaceuticals in mind, the mixer features a seamless, mirror or matte polished finish, making it easy both to clean and maintain. Safety is prioritized via integrated overload protection and secure grills, minimizing risk during operation. The smooth, stainless steel surfaces limit residue buildup, supporting high hygiene standards.

Flexible Applications and Customization

Adaptable to a variety of needs, this ribbon mixer can be fitted with optional attachments such as spray nozzles, weighing systems, and heating or cooling jackets. Available in capacities from 500 to 5000 liters, and customizable in size, it's suitable for both small-scale and high-volume processing facilities.

FAQ's of Ribbon Mixer Blender:

Q: How does the ribbon mixer blender ensure uniform mixing for different materials?

A: The twin ribbon agitator, featuring inner and outer ribbons, moves materials in opposing flows for effective lifting and folding throughout the mixing chamber. This design enables thorough mixing of powders, granules, spices, chemicals, and even feed or pharmaceuticals within 10-20 minutes per batch.Q: What safety measures are in place during the operation of this mixer blender?

A: The mixer is equipped with an overload protection system and safety grills, reducing the risk of accidents during use. These features ensure safe manual control and decrease the likelihood of mechanical or operator-related incidents.Q: When should optional attachments like a spray nozzle or weighing system be used?

A: Optional attachments are recommended for specialized processes. Use a spray nozzle for liquid additions during blending, a weighing system for precise ingredient measurement, or a heating/cooling jacket to regulate product temperature as required by your process.Q: Where can the ribbon mixer blender be installed in a processing facility?

A: This equipment is designed for floor-mounted installation and can be placed in industrial environments such as food processing plants, chemical factories, or pharmaceutical production lines. Its dimensions and weight are customizable to fit space and workflow requirements.Q: What is the cleaning process for the ribbon mixer blender?

A: Thanks to its smooth, mirror or matte polished stainless steel surfaces, the blender is easy to clean. After each batch, residue can be quickly removed with water and mild detergent. The design minimizes dead spots, ensuring thorough sanitation and reducing downtime between production cycles.Q: What benefits does the robust gearbox-driven design offer?

A: The gearbox-driven mechanism provides reliable, maintenance-minimal power transmission, resulting in consistent mixing action and extended equipment lifespan. This design supports low noise levels and optimal energy efficiency during operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

Starch Paste Preparation Kettle

Power : 35 kW (vary by capacity)

Control Mode : Other, Manual / Semiautomatic

Capacity : 50 to 500 Liters (customizable)

Voltage : 220V / 415V

Usage & Applications : Textile, Pharmaceuticals, Paper, and Food Industries for paste making and mixing

Phase : Single Phase / Three Phase

Ultra Vacuum Mixer

Power : 37.5 kW

Control Mode : Automatic

Capacity : 50200 Liters (customizable)

Voltage : 220V/380V

Usage & Applications : Mixing, emulsifying, homogenizing viscous products in cosmetic, pharmaceutical, chemical, food industries

Phase : Three Phase

Hardners Resin Processing Plant Machine

Power : 1050 kW depending on model

Control Mode : Other, PLC / Manual

Capacity : 5005000 Liters per batch

Voltage : 220415 V

Usage & Applications : Mixing, processing and curing of hardener resins; adhesive, paints, coatings, building chemicals

Phase : Three Phase

High Shear Mixer Granulator-HSMG Rapid Mixer Granulator - RMG

Power : 5 kW to 30 kW (varies by model size)

Control Mode : Other, Automatic / SemiAutomatic

Capacity : 10 to 600 kg per batch (varies as per model)

Voltage : 380 V / 415 V AC

Usage & Applications : Wet granulation for pharmaceutical, food, chemical, and cosmetic industries

Phase : 3 Phase

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry