PROOFER

PROOFER Specification

- Power Source

- Electric

- Speed Mode

- Fixed

- Phase

- Single Phase

- Feeding System

- Manual Tray Loading

- Features

- Uniform Steam Distribution, Stainless Steel Construction, Low Maintenance

- Operating Temperature

- 30C to 110C

- Noise Level

- Low

- Heating Method

- Electric Heating

- Function Type

- Fermentation

- Machine Type

- Vertical Proofer

- Frequency

- 50/60 Hz

- Automation Grade

- Automatic

- Product Type

- Bakery Proofer

- General Use

- Bread and Bakery Fermentation

- Material

- Stainless Steel

- Type

- Dough Proofer

- Capacity

- 16 Trays

- Weight (kg)

- 65

- Product Shape

- Rectangular

- Computerized

- No

- Automatic

- Yes

- Control System

- Digital Timer Control

- Installation Type

- Free Standing

- Voltage

- 220-240 V

- Power

- 1.5 kW

- Dimension (L*W*H)

- 815 x 585 x 1865 mm

- Raw Material

- Stainless Steel

- Feature

- Corrosion Proof, Low Nois, Energy Saving

- Color

- Silver

PROOFER Trade Information

- Payment Terms

- Cash on Delivery (COD), Telegraphic Transfer (T/T), Western Union, Paypal

- Delivery Time

- 1 MONTH Months

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- WOODEN BOX

- Main Export Market(s)

- Australia, Central America, North America, Eastern Europe, Western Europe, Middle East, Africa, South America, Asia

- Main Domestic Market

- All India

About PROOFER

Versatile Application and Competitive Edge

The PROOFER is primarily used for bread and bakery fermentation, mixing, and dough development in commercial settings. Its primary competitive advantages include corrosion-proof construction, uniform steam distribution, and an adjustable humidity control system. This formidable equipment serves bakeries, hotels, and food processing industries, ensuring consistent results across diverse application media and maintaining energy-efficient operation.

Seamless Payment and Export Procedures

Our payment terms are adaptable, allowing secure shipping arrangements. We offer quotation-based procurement tailored to individual export market needs. Main export destinations include Europe, Asia, and the Middle East, ensuring flexible logistics solutions. Sample policy details are available upon request, guaranteeing a smooth initiation process for dealers, exporters, and fabricators requiring reliable, high-performance bakery proofers.

FAQs of PROOFER:

Q: How is the operating temperature of the PROOFER adjusted for optimal dough fermentation?

A: The PROOFERs operating temperature ranges from 30C to 110C and can be precisely managed using the digital timer control, ensuring optimal conditions for dough fermentation and bakery products.Q: What are the benefits of using a stainless steel PROOFER in a bakery or hotel environment?

A: Crafted from corrosion-proof stainless steel, this PROOFER provides durability, energy saving, and low maintenance, making it an ideal choice for bakeries and hotels requiring consistent performance and longevity.Q: When should the water tank be refilled during continuous operation?

A: The PROOFER is equipped with a 5-liter water tank; regular monitoring is recommended during extended use to ensure uninterrupted humidity control and uniform steam distribution.Q: Where can the PROOFER be installed, and does it require permanent fixtures?

A: With its free-standing design and caster wheels for easy mobility, the PROOFER can be installed wherever needed within bakeries, hotels, or food processing unitsno permanent fixtures required.Q: What is the process for loading trays and maintaining steam distribution?

A: Manual tray loading is performed through the single chamber door, while the automatic function ensures uniform steam distribution for every batch of dough, facilitating efficient fermentation.Q: How does the low noise feature benefit the user during bakery operations?

A: The low noise level allows for a quieter working environment, minimizing disturbance in busy kitchens and ensuring smoother, more comfortable operations for all staff.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bakery Equipments Category

BACK BAR CHILLER

Installation Type : Other, Free Standing

Automation Grade : Automatic

Feature : Other, Refrigerated, Energy Efficient, LED Lighting

Material : Other, Stainless Steel, Glass Door

Function Type : Mixing Other, Cooling

Type : Other, Back Bar Chiller

MEAT SLICER

Installation Type : Other, Countertop

Automation Grade : SemiAutomatic

Feature : Other, Corrosion Resistant, Easy to Clean

Material : Other, Stainless Steel and Aluminum Alloys

Function Type : Mixing Other, Slicing

Type : Other, Food Processing Machinery

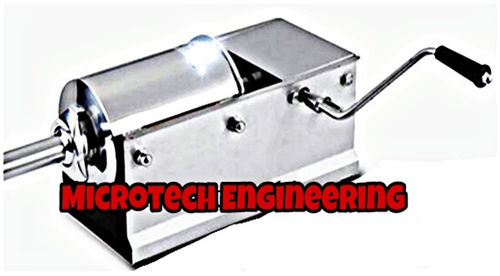

MANUAL SAUSAGE FILLER

Installation Type : Other, Tabletop

Automation Grade : Manual

Feature : Other, Easy to Operate, Durable, Portable

Material : Stainless Steel

Function Type : Mixing Other, Filling

Type : Other, Manual Sausage Filler

SOAP TUREEN

Installation Type : Other, Portable

Automation Grade : Manual

Feature : Other, With lid, smooth finish

Material : Other, Plastic

Function Type : Mixing Other, Storage

Type : Other, Soap Holder

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry