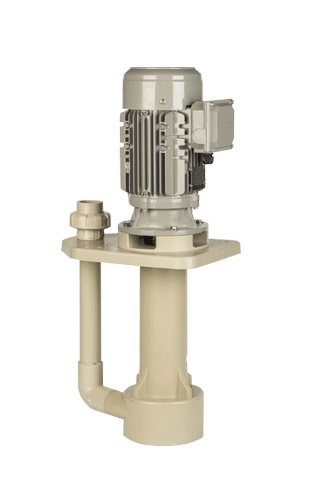

PP Chemical Process Pump

PP Chemical Process Pump Specification

- Inlet/Outlet

- 25 mm x 25 mm to 100 mm x 100 mm

- Flow Rate

- Up to 70 m/hr

- Mounting Type

- Horizontal Foot Mounted

- Control System

- Manual / DOL starter / Star-Delta

- Noise Level

- Low Noise

- Speed

- 2900 RPM

- Caliber

- 25 mm 100 mm

- Frequency

- 50 Hz / 60 Hz

- Head Size

- Up to 35 meters

- Theory

- Centrifugal Pump

- Features

- Corrosion Resistant, Leak Proof, Easy Maintenance

- Working Temperature

- Up to 80C

- Discharge Pressure

- 3.5 kg/cm max

- Max Suction

- Up to 3 meters

- Voltage

- 220V / 380V

- Material

- Polypropylene (PP)

- Structure

- Single Stage

- Power

- 0.5 HP to 10 HP

- Standard

- ISO 2858 / DIN 24256

- Fuel Type

- Electric

- Pressure

- Up to 3.5 kg/cm

- Usage

- Chemical Processing, Acid Handling, Electroplating, Effluent Treatment

- Application

- Transfer of corrosive and hazardous chemicals

- Suction Type

- End Suction

- Seals Type

- Mechanical Seal

- Priming

- Self Priming / Non-Self Priming

- Pump Type

- Chemical Process Pump

- Capacity

- 15 LPM to 1200 LPM

- Impeller Type

- Close / Semi Open

- Bearing Type

- SKF / Equivalent Heavy Duty Bearing

- Connection Standard

- ANSI / DIN Flanges

- Protection Class

- IP55

- Surface Finish

- Smooth, Chemical Resistant Coating

- Shaft Material

- SS 316

- Color

- Blue / White (customizable)

- Weight

- Approx. 20-85 kg

- Max Solid Handling

- Up to 10 mm

PP Chemical Process Pump Trade Information

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 200 Per Year

- Delivery Time

- 200 Years

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- WOODEN CHARGE

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2008 MSME

About PP Chemical Process Pump

Versatile Applications for Demanding Environments

The PP Chemical Process Pump is purpose-built for diverse industrial settings, meeting the needs of chemical processing, acid handling, electroplating, and effluent treatment plants. Its robust polypropylene design ensures enduring performance for both self priming and non-self priming operations. This pump excels in end suction systems, making it a preferred choice where the transfer of corrosive and hazardous chemicals is essential, combining safety with operational flexibility across a wide range of applications.

Professional Packaging and Global Export Standards

Each PP Chemical Process Pump undergoes meticulous drop-off packaging, ensuring reliable delivery and secure product integrity. Our offer includes sturdy export-standard crating, with clear asking price transparency for all our dealer, distributor, exporter, and supplier partners. Supporting main export markets worldwide, each unit is supplied with ISO 2858/DIN 24256 certification, assuring you of our commitment to excellence and global standards in every shipment.

FAQs of PP Chemical Process Pump:

Q: How can the PP Chemical Process Pump enhance chemical handling in my industry?

A: This pump is engineered for safe and efficient transfer of corrosive and hazardous chemicals, offering robust corrosion resistance and leak-proof operation, making it invaluable for demanding industries like chemical processing, electroplating, and effluent treatment.Q: What is the process for installing the PP Chemical Process Pump?

A: Installation is straightforward: the pump is horizontally foot-mounted and easily connected to existing pipelines using ANSI or DIN flanges. It accommodates various control systems, such as manual, DOL starter, or star-delta arrangements.Q: When should I select the semi open impeller type over the close impeller?

A: Choose the semi open impeller when handling fluids with suspended solids up to 10mm or slurries, as it provides superior solid handling capability compared to the close impeller.Q: Where can the PP Chemical Process Pump be used aside from chemical processing?

A: Apart from chemical processing plants, it is suitable for acid handling units, electroplating facilities, effluent and wastewater treatment plants, and any operation requiring reliable transfer of corrosive substances.Q: What are the benefits of the polypropylene material used in the pump?

A: Polypropylene offers excellent chemical resistance, durability, and low maintenance, ensuring a long service life even in aggressive chemical environments.Q: How do I ensure the correct usage and maintenance of this pump?

A: Refer to the detailed user manual included, follow recommended maintenance intervals, utilize the proper mechanical seal, and select SKF or equivalent heavy-duty bearings for optimal performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PP Chemical Pump Category

Ice Cream Transfer Pump

Minimum Order Quantity : 01 Piece

Pump Type : Other, Lobe Pump

Usage : Other, Ice Cream Transfer, Food Processing

Material : Stainless Steel (SS316/SS304)

Features : CIP/SIP Compatible, Easy Cleaning, Hygienic, Compact Design

Pressure : Other, Max 8 Bar

Scrubber Liquid Transfer Pump

Pump Type : Other, Centrifugal Pump

Usage : Other, Industrial Scrubber liquid transfer

Material : PP (Polypropylene) / FRP

Features : Corrosion resistant, efficient operation, suitable for chemicals

Pressure : Other, 2.4 kg/cm

Vertical Chemical Pumps

Pump Type : Other, Vertical Chemical Pump

Usage : Other, Chemical Handling

Material : Polypropylene (PP), PVDF, Stainless Steel

Features : Corrosion Resistant, Leak Proof Design, Easy Maintenance

Pressure : Other, Up to 3.5 bar

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry