Call: 08071931448

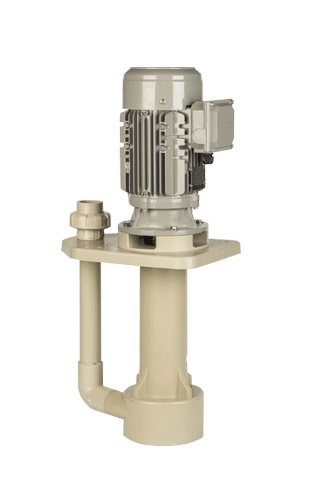

Ice Cream Transfer Pump

MOQ : 01 Piece

Ice Cream Transfer Pump Specification

- Theory

- Rotary Lobe Pump

- Discharge Pressure

- Max 8 Bar

- Frequency

- 50 Hz

- Working Temperature

- -5C to +90C

- Flow Rate

- 1000-8000 LPH

- Caliber

- 40 mm

- Voltage

- 220-240V, 50 Hz

- Speed

- 1440 RPM

- Features

- CIP/SIP Compatible, Easy Cleaning, Hygienic, Compact Design

- Head Size

- Upto 30 Mtrs

- Inlet/Outlet

- 1.5/1.5 (DN40)

- Mounting Type

- Base Mounted

- Max Suction

- 4m

- Control System

- Manual/Auto (Optional)

- Noise Level

- Low

- Material

- Stainless Steel (SS316/SS304)

- Structure

- Horizontal

- Power

- 2 HP - 5 HP

- Standard

- Sanitary/Hygienic Design

- Fuel Type

- Electric

- Pressure

- Max 8 Bar

- Usage

- Ice Cream Transfer, Food Processing

- Application

- Ice Cream, Dairy, Food Products

- Suction Type

- Positive Displacement

- Seals Type

- Mechanical Seal

- Priming

- Self Priming

- Pump Type

- Lobe Pump

- Capacity

- Up to 8000 LPH

Ice Cream Transfer Pump Trade Information

- Minimum Order Quantity

- 01 Piece

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 200 Pieces Per Year

- Delivery Time

- 200 Years

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- WOODEN CHARGE

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Central America, South America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2008 MSME

About Ice Cream Transfer Pump

Ice Cream Transfer PumpMICROTECH ENGINEERING

Lobe pumps are used in a variety of industries including, pulp and paper, chemical, food, beverage, Pharmaceutical, and biotechnology. They are popular in these Diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics. These pumps offer a variety of lobe options including single, biwing, tri-lobe (shown), and multi-lobe.Rotary lobe pumps are Non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self- priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous.

Hygienic and Durable Construction

Engineered with high-grade SS316/SS304 stainless steel and a mirror-polished finish, this rotary lobe pump meets strict sanitary standards. Its compact and robust design ensures reliability for continuous operation in the food industry, especially in ice cream and dairy processing applications. All contact surfaces are easy to clean and resist corrosion, ensuring product integrity.

Efficient Performance and Versatile Operation

Capable of handling viscosities up to 1,00,000 cP and particle sizes up to 8 mm, the pump delivers precise, low-noise operation. The positive displacement system provides consistent suction up to 4 meters and handles flow rates of 1,0008,000 LPH at pressures up to 8 Bar. The unit performs optimally in a wide temperature range, making it highly adaptable for varying production environments.

Advanced Features for Safe Food Handling

Incorporating mirror polishing, mechanical seals, Tri-Clamp/SMS Union ports, and CIP/SIP compatibility, the pump upholds rigorous hygiene protocols. Manual or automatic control operation modes offer operational flexibility. Its base-mounted, floor-standing structure ensures straightforward installation and maintenance for food processing facilities in India and beyond.

FAQs of Ice Cream Transfer Pump:

Q: How is the Ice Cream Transfer Pump installed and what connection types are available?

A: The Ice Cream Transfer Pump is designed for floor-standing, base-mounted installation and features port connections compatible with both Tri-Clamp and SMS Union fittings. These connections ensure quick, secure attachment to existing pipelines and simplify maintenance or cleaning processes.Q: What types of products can be processed with this pump and what is the maximum allowed viscosity?

A: This rotary lobe pump is ideal for transferring viscous products such as ice cream, dairy, and other food items. It efficiently pumps fluids with viscosities up to 1,00,000 cP and is capable of handling soft solids up to 8 mm, making it suitable for a wide range of food processing applications.Q: Where can this pump be used, and which industries benefit most from its features?

A: The Ice Cream Transfer Pump is widely used in the ice cream, dairy, and general food processing industries. Its hygienic, reliable construction and sanitary design benefit manufacturers, exporters, suppliers, and fabricators seeking efficient and safe product handling.Q: What is the cleaning process for this pump, and is it compatible with CIP/SIP systems?

A: This pump is designed for ease of cleaning and fully compatible with Clean-in-Place (CIP) and Sterilize-in-Place (SIP) systems. Its mirror-polished surfaces and sanitary construction prevent residue buildup, supporting quick and thorough cleaning without disassembly.Q: How does the pump handle variations in product temperature and flow requirements?

A: Equipped to operate between -5C and +90C, the pump manages a broad spectrum of product temperatures. Its rotary lobe mechanism supports variable flow rates from 1,000 to 8,000 LPH, adjusted according to the process needs for optimal efficiency.Q: What are the main benefits of its rotary lobe and positive displacement design?

A: The rotary lobe and positive displacement design enables gentle handling of delicate food products, reduces shear, and maintains product quality. It provides self-priming capabilities and unwavering suction across a range of viscosities, contributing to smooth, reliable operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PP Chemical Pump Category

PP Chemical Process Pump

Minimum Order Quantity : 01

Pump Type : Other, Chemical Process Pump

Material : Polypropylene (PP)

Pressure : Other, Up to 3.5 kg/cm

Features : Corrosion Resistant, Leak Proof, Easy Maintenance

Usage : Other, Chemical Processing, Acid Handling, Electroplating, Effluent Treatment

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry