Lacquer Polish Making Machine

Lacquer Polish Making Machine Specification

- Condition

- New

- Power

- 7.5-10 Hp

- Product Type

- Polish Making Machine

- General Use

- Manufacturing of Lacquer Polish

- Material

- Stainless Steel (SS304/SS316)

- Capacity

- 200-1000 Litre/Batch (customizable)

- Weight (kg)

- 1200 kg (approx)

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Available

- Mixer Type

- Stirrer/Mixer Blender

- Shaft

- Stainless Steel Shaft

- Drive Type

- Gearbox Drive

- Voltage

- 415 V / 3 Phase

- Motor

- Heavy Duty Electric Motor

- Dimension (L*W*H)

- 2500 x 1200 x 1800 mm (approx)

- Feature

- Low Maintenance, Corrosion Resistant

- Color

- Silver/Grey

- Mixing Speed

- 0-65 RPM, Variable

- Agitator Type

- Anchor/Propeller/Customized

- Installation Service

- Available

- Sealing Type

- Mechanical Seal/Stuffing Box (Optional)

- Noise Level

- < 75 dB

- Mixer Design

- Closed Lid with Viewing Window

- Heating System

- Optional Electric/Oil Jacketed

- Safety System

- Overload & Overheat Protection

- Working Temp.

- Ambient to 120°C

- Discharge Method

- Bottom Valve Discharge

- Portability

- Mounted on Castor Wheels (Optional)

- Control Panel

- Digital Automatic Panel

- Application Industry

- Paint, Varnish & Polish Manufacturing

- Tank Thickness

- 4-5 mm

- Surface Finish

- Polished/Mirror Finish

Lacquer Polish Making Machine Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Paypal, Western Union, Telegraphic Transfer (T/T), Delivery Point (DP), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Lacquer Polish Making Machine

Lacquer Polish Making Machine

Characteristics:

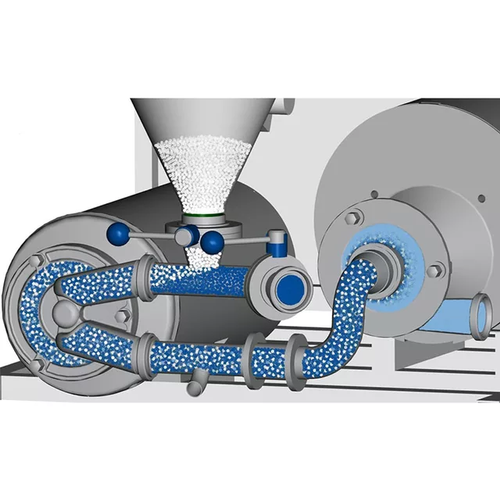

- New structure using new super shearing structure, new stator and rotor coordination, radial and axial double-sided shearing technology, more comprehensive and thorough of shearing dispersion effects.

- New flow field the lower rotor and the upper axial assisted impeller powerful suction, injection along the stator circumferential and axial, more obvious mixing effects of materials in the whole container and more comprehensive recycling.

- More Durable using spindle protection sleeve technology, spindle security against wearing in the case of high-speed operation, solveing the issue of spindle wearing by the greatest extent.

- More Stable shaft support auxiliary, increasing the number of stiffening ring at the central position of auxiliary supporting bar, minimizing the impact of spindle vibration under high speed operation to ensure the equipment long-term stable operation.

- More Efficient having the upper, lower, upper & lower suction three new models, selecting optimal structural model according to material properties and processing demands, more efficient and energy saving.

Process application

- Soluble (or miscible materials) solid and liquid in accelerated dissolution.

- Immiscible solid-liquid suspensions in ultra fine dispersion and mixing.

- Immiscible liquid-liquid phase solution in inclusive micro-emulsion.

- Nanomaterial aggregates in strong deploymerization and superfine dispersion.

- High-viscosity material powder-liquid in overall mixing and superfine dispersion.

- Particles and fat balls in solution in superfine shattering and homogenizing.

- Animal and plant tissues in superfine shattering processing.

Precision Mixing for Superior Polish Quality

Utilizing a variable speed agitator and closed lid design with a viewing window, this machine ensures uniform blending of lacquer polish ingredients. The advanced control panel allows operators to precisely adjust mixing parameters, leading to consistent batch quality and reduced wastage. Stainless steel construction guarantees product purity and minimizes contamination risks.

Efficient Heating and Safe Operation

Choose between electric or oil jacketed heating systems to meet process requirements up to 120C. Integrated overload and overheat protection, combined with the mechanical seal or stuffing box options, safeguard both operators and machinery. Noise emission stays below 75 dB, supporting a comfortable work environment in any manufacturing unit.

Flexible Installation and Customization

Designed for use by traders, suppliers, wholesalers, and fabricators throughout India, this machine is available in several capacities and agitator options. Its corrosion-resistant build and low maintenance requirements make it ideal for continuous production cycles. Optional castor wheels enhance portability, while installation services ensure seamless setup at your facility.

FAQ's of Lacquer Polish Making Machine:

Q: How does the Lacquer Polish Making Machine optimize the mixing process?

A: The machine utilizes variable speed control (0-65 RPM) and customizable agitator types-anchor, propeller, or custom designs-to ensure thorough and homogeneous mixing. The closed lid with a viewing window allows monitoring, while the digital automatic panel provides precise setting adjustments for each batch.Q: What safety features are integrated into this machine?

A: It is equipped with overload and overheat protection systems to prevent damage to the motor or heating elements. Depending on the selection, mechanical seals or stuffing boxes further secure the mixing vessel, minimizing leaks and ensuring safe operation.Q: When should the optional heating system be used?

A: The optional electric or oil jacketed heating system is recommended when the lacquer polish formulation or process requires elevated temperatures, supporting consistent heating up to 120C for optimal blending and chemical reactions.Q: Where can this machine be installed and who are the target users?

A: Installation services are available throughout India, and the machine is suited for paint, varnish, and polish manufacturers, including dealers, distributors, exporters, retailers, and fabricators seeking reliable production equipment.Q: What are the advantages of the bottom valve discharge method?

A: The bottom valve discharge ensures efficient, complete draining of the batch with minimal manual intervention, reducing product loss and facilitating easy cleaning between production cycles.Q: How does the computerized automatic control benefit operational efficiency?

A: The digital automatic panel with PLC control streamlines batch operations by allowing programmable sequences, accurate mixing times, and real-time adjustments, ultimately enhancing output consistency and reducing operator workload.Q: What benefits does the stainless steel construction provide?

A: Manufactured from high-grade stainless steel (SS304/SS316), the machine offers excellent corrosion resistance, ensures hygienic processing, maintains product integrity, and supports easy maintenance for prolonged durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Processing Plants Category

WATER PROOFING CHEMICAL PLANT

Capacity : 10005000 L/Batch

Shaft : Other, Single / Double Shaft Agitator

Automatic : Yes

Drive Type : Electric

Voltage : 415 V

Feature : Other, Corrosion resistant, High efficiency, Easy operation

Grease Homogenize Mixer

Capacity : 2002000 Liters (Customizable)

Shaft : Other, Single or Double Shaft (As per order)

Automatic : Yes

Drive Type : Electric

Voltage : 220V/380V/415V, 50/60Hz

Feature : Other, High Shear Mixing, Uniform Homogenization, Robust Construction

Sanitizer Filter Press

Capacity : 100500 Liters/Hour (customizable)

Shaft : Other, SS Shaft

Automatic : Other, Semi Automatic

Drive Type : Electric

Voltage : 220240V, 50 Hz

Feature : Other, Leak proof, Easy to operate, Corrosion resistant

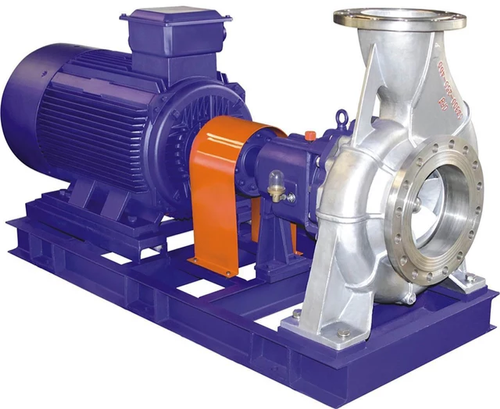

Chemical Re-circulation Process Pump

Capacity : Up to 350 m3/hr

Shaft : Other, High Strength Stainless Steel

Automatic : Other, SemiAutomatic

Drive Type : Other, Direct Coupled

Voltage : 380415 V

Feature : Other, Corrosion Resistant, Leak Proof, Low Maintenance

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry