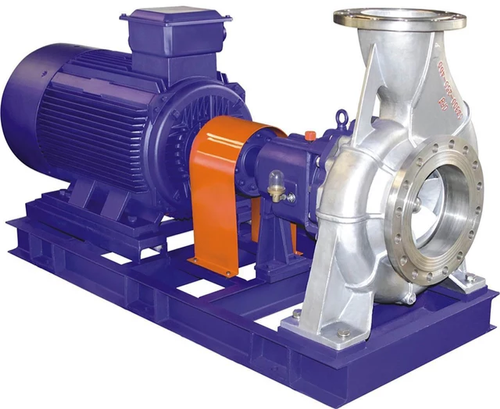

Chemical Re-circulation Process Pump

Chemical Re-circulation Process Pump Specification

- Power

- Up to 15 HP

- Condition

- New

- Product Type

- Chemical Process Pump

- General Use

- Chemical Recirculation, Process Industries

- Material

- Cast Iron / Stainless Steel

- Capacity

- Up to 350 m3/hr

- Weight (kg)

- Approx. 65 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- PLC Control

- Optional

- Mixer Type

- Single Stage

- Shaft

- High Strength Stainless Steel

- Drive Type

- Direct Coupled

- Voltage

- 380-415 V

- Motor

- 3 Phase, TEFC / Flameproof

- Dimension (L*W*H)

- 400mm x 280mm x 370mm (typical)

- Feature

- Corrosion Resistant, Leak Proof, Low Maintenance

- Color

- Blue / Customized

- Inlet Size

- 40 mm to 100 mm

- Surface Finish

- Epoxy Coated

- Sealing Type

- Mechanical Seal / Gland Packing

- Maximum Solid Handling

- Up to 10 mm

- Discharge Size

- 32 mm to 80 mm

- Service Life

- Long, Designed for 24/7 Operation

- Compliance

- ISO 9001:2015 Certified

- Flow Rate

- Adjustable depending on application

- Noise Level

- Low (< 80 dB)

- Application

- Acids, Alkalis, Solvents, Process Liquids

- Head Range

- Up to 80 meters

- Operating Temperature

- Up to 150°C

- Pump Casing

- Heavy Duty Cast Construction

- Mounting Type

- Base Mounted

- Impeller Type

- Closed / Semi-open

Chemical Re-circulation Process Pump Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Western Union, Paypal, Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Per Year

- Delivery Time

- 1 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, Western Europe, Central America, Middle East, South America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Chemical Re-circulation Process Pump

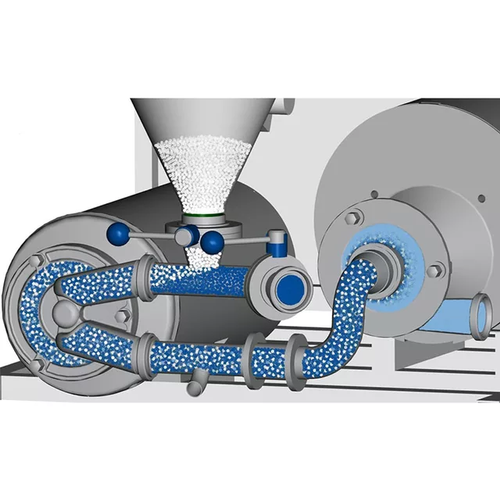

CHEMICAL RECIRCULATION PROCESS PUMP

Head : 48 meter

Capacity : 33 m3/h

Delivery size : 12mm to 65 mm

Temperature : -10 to 95 degree Celsiu

Test pressure : 10 kg/cm2

Standard futures :

Centrifugal single stage

Flange as per din standard

Back pull out design

Open / close impeller

Shaft sealing by single / doable mechanical seal

Sealed grease lubricated , deep grove ball bearing

He pump handle liquid having viscosities up to 1500 centriole

Also with flame proof motor

Optional futures :

Shaft sealing by gland packing

Bearing lubricating by oil

ANSI drilling on DIN flange

Trolley mounting arrangement

Various type of connection

APPLICATION

Milk, Cream, Butter Milk Condensed Milk

Fruit Juice, Beer, Wine, Sugar Syrup

Vitamin Solutions, Sugar & Confectionery.

R O Water, DM water, Pure Water.

Water for Injection (WFI)

Vegetable Oil, Mineral Oil, Lub Oil etc.

Pharmaceutical Formulations, Syrup etc.

Alkaline Solutions / Alcoholic Drink

Acids, Fine Chemical

Textile Sizing, Dyeing & Finishing System

Natural Cellulose Fiber / Synthetic Fiber System

Hot & Cold Water Pumping.

Bottling Plants, Soft Drinks & Distillery

Food Processing / Liquid Food Stuff

Water Treatment Plat

Colour dyes and Pigments / Paint

Descaling Applications, Paper & Cement Industrie

Detergent, Soaps, Paste & Shampoo

food processing plant

wet scrubber

Superior Construction and Materials

Built with heavy duty cast iron or stainless steel, the pump's epoxy coating provides corrosion resistance and durability. Its robust construction ensures reliable operation under demanding conditions, making it suitable for continuous industrial applications.

Versatile Performance for Process Industries

Adjustable flow rates and head range, plus multiple impeller types, allow customized performance for different process liquids, including acids, alkalis, and solvents. It can be integrated with optional PLC control and flameproof motors for enhanced safety and automation.

Low Maintenance and Enhanced Safety

Designed for leak-proof operation with mechanical seals or gland packing, the pump minimizes downtime and maintenance. Its quiet operation and compliance with ISO 9001:2015 standards ensure safe and efficient performance in chemical recirculation tasks.

FAQ's of Chemical Re-circulation Process Pump:

Q: How does the Chemical Re-circulation Process Pump handle corrosive liquids and solids?

A: The pump features heavy duty cast iron or stainless steel construction and an epoxy-coated surface finish, making it corrosion resistant. It can safely manage solids up to 10 mm in diameter, making it ideal for recirculating chemical process liquids.Q: What are the benefits of using mechanical seals or gland packing in this pump?

A: Mechanical seals or gland packing reduce leakage and enhance reliability. Both options ensure the pump remains leak-proof during operation, minimizing maintenance needs and ensuring long service life in demanding chemical environments.Q: When is this pump recommended for use in an industrial setting?

A: This pump is designed for 24/7 operation and is ideal for chemical recirculation in process industries, especially where continuous handling of acids, alkalis, or solvents is required. It is suitable for new installations or replacement in existing systems.Q: Where can the Chemical Re-circulation Process Pump be installed?

A: The pump is base-mounted and suitable for industrial process plants. It accommodates various installation requirements, with inlet sizes from 40 mm to 100 mm and discharge sizes from 32 mm to 80 mm, making it adaptable to different piping setups.Q: What is the process for adjusting the flow rate and ensuring optimal performance?

A: Flow rate adjustment depends on application requirements, typically managed through pump speed control or optional PLC integration. Regular monitoring of discharge and inlet parameters helps maintain optimal performance for specific process liquids.Q: How does the pump contribute to low noise and safe operation?

A: With a noise output below 80 dB and certified to ISO 9001:2015 standards, the pump ensures quiet and safe operation. Optional flameproof motors and direct coupling further enhance safety and reliability in hazardous environments.Q: What usage advantages does this pump offer compared to standard pumps?

A: Its corrosion resistance, leak-proof design, ability to handle solids, and compatibility with harsh chemicals make it superior for chemical recirculation. The pump's low maintenance, long service life, and customizable operation support increased productivity and reduced downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Processing Plants Category

Lacquer Polish Making Machine

PLC Control : Other, Available

Voltage : 415 V / 3 Phase

Automatic : Yes

Capacity : 2001000 Litre/Batch (customizable)

Product Type : Polish Making Machine

Dimension (L*W*H) : 2500 x 1200 x 1800 mm (approx)

WATER PROOFING CHEMICAL PLANT

PLC Control : Other, Available

Voltage : 415 V

Automatic : Yes

Capacity : 10005000 L/Batch

Product Type : Water Proofing Chemical Plant

Dimension (L*W*H) : 5200mm x 2400mm x 3400mm

Sanitizer Filter Press

PLC Control : No

Voltage : 220240V, 50 Hz

Automatic : Other, Semi Automatic

Capacity : 100500 Liters/Hour (customizable)

Product Type : Sanitizer Filter Press

Dimension (L*W*H) : 1100 mm x 500 mm x 900 mm

Grease Homogenize Mixer

PLC Control : Yes

Voltage : 220V/380V/415V, 50/60Hz

Automatic : Yes

Capacity : 2002000 Liters (Customizable)

Product Type : Industrial Mixer

Dimension (L*W*H) : Customizable as per requirement

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry