GRANULE FILLER

GRANULE FILLER Specification

- Efficiency (%)

- Up to 99.9%

- Filter Type

- Granule Filler

- Filtration Grade

- Medium / Fine

- Capacity

- Varies by application

- Pressure

- 0.6 MPa max

- Media Type

- Granule

- Flow Rate

- 50 - 5000 LPH (customized)

- Connecting Type

- Threaded / Flanged

- Temperature Range

- -20C to 80C

- Cleaning Method

- Manual or Backwash

- Condition

- New

- Material

- Stainless Steel / Polypropylene

- Mesh

- 100 - 400 micron (customizable)

- Diameter

- 50 mm - 600 mm

- Construction

- Welded / Modular

- Medium Filter

- Granule Media

- Weight

- Varies as per size

- Shape

- Cylindrical / Custom available

- Feature

- High strength, Corrosion resistance, Durable construction

- End Connection Size

- 1" - 12" (custom available)

- Packaging

- Box or Customized

- Surface Finish

- Matt / Polished / Coated

- Usage Life

- Up to 5 years (with proper maintenance)

- Application

- Water treatment, Industrial filtration, Chemical processing

- Color

- Natural / Silver / White

- Internal Volume

- As per requirement

GRANULE FILLER Trade Information

- Payment Terms

- Cash on Delivery (COD), Telegraphic Transfer (T/T), Western Union, Paypal, Cheque

- Delivery Time

- 1 MONTH Months

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- WOODEN BOX

- Main Export Market(s)

- Australia, North America, Eastern Europe, Africa, Western Europe, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

- Certifications

- AN ISO 9001:2015 CERTIFIED

About GRANULE FILLER

Versatile Performance Across Industries

GRANULE FILLER sets a new benchmark in water treatment, industrial filtration, and chemical processing. Its robust granule media enables medium to fine filtration with customizable mesh sizes from 100 to 400 microns, perfectly tailored for your application. Available in cylindrical or custom shapes, it delivers high flow rates and consistent performance under various conditions. Each filter promises corrosion resistance, durable construction, and a seamless fit with threaded or flanged connections for both new and replacement setups.

Certifications, Domestic and Export Markets, Premium Packaging

Our GRANULE FILLER complies with premium industry standards, making it suitable for Indias dynamic domestic market as well as international export markets. As a trusted dealer, manufacturer, and supplier, we ensure each filter is meticulously boxed or custom packed for secure shipping. With a focus on quality, all fabrication and packaging procedures follow stringent protocols, guaranteeing each unit arrives in pristine, ready-to-use conditionreflecting our commitment to excellence and customer satisfaction.

FAQs of GRANULE FILLER:

Q: How do I choose the right GRANULE FILLER specification for my application?

A: Selecting the correct GRANULE FILLER is based on factors such as your required flow rate, filtration grade, connection size, and medium type. Customization options are available to ensure the filter fits precisely into your specific water treatment, industrial, or chemical processing setup.Q: What benefits does the GRANULE FILLER offer for industrial usage?

A: The GRANULE FILLER provides high-strength, corrosion resistance, and durability, ensuring reliable filtration performance. Its customizable design suits diverse media types, applications, and flow rates, providing up to 99.9% efficiency and a usage life of up to 5 years with proper maintenance.Q: Where can GRANULE FILLER be used effectively?

A: This filter is optimized for water treatment plants, chemical processing facilities, and various industrial filtration applications. Its modular and welded construction allows integration into both new installations and existing systems.Q: What is the process for cleaning and maintaining the GRANULE FILLER?

A: GRANULE FILLER can be cleaned manually or through backwash, depending on the setup. Regular maintenance, including periodic cleaning and inspection for media integrity, maximizes its efficiency and extends its operating life.Q: When should the GRANULE FILLER be replaced or serviced?

A: With regular maintenance, the GRANULE FILLER typically lasts up to 5 years. It should be serviced according to usage conditions, with replacements considered if there is a significant drop in filtration efficiency or visible damage to the unit.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PACKAGING AND LABELING MACHINES Category

HYDRAULIC HIGH LIFT PALLET TRUCK

Condition : New

Shape : Rectangular platform with fork arms

Construction : Other, Robust welded frame

Feature : High lift for easy pallet stacking and transport

Material : Heavyduty Steel

Cleaning Method : Other, Wipe Clean

VACUUM PACKING MACHINE(double Chamber)

Condition : New

Shape : Rectangular

Construction : Other, Robust Construction for Industrial Use

Feature : Double Chamber, Heavy Duty, Stainless Steel Body, Digital Control Panel, High Vacuum Efficiency

Material : Stainless Steel

Cleaning Method : Other, Manual Cleaning

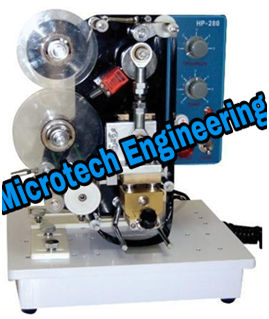

Automatic hot stamp machine

Condition : New

Shape : Rectangular Base, Vertical Structure

Construction : Other, Heavyduty, industrial build

Feature : Fully automatic operation, digital control, precision stamping

Material : Sturdy steel body with heatresistant components

Cleaning Method : Other, Manual Cleaning Required

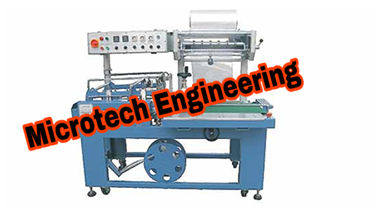

AUTOMATIC L-SEALER

Condition : New

Shape : Rectangular

Construction : Other, Robust heavy duty build

Feature : Automatic operation, Programmable controls, Photoelectric sensor, Adjustable conveyor speed, Shrink wrapping compatible

Material : Mild Steel Body with Powder Coating

Cleaning Method : Manual

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry