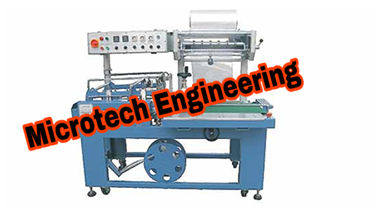

AUTOMATIC L-SEALER

AUTOMATIC L-SEALER Specification

- Cleaning Method

- Manual

- Temperature Range

- Up to 250C (Shrink Tunnel)

- Capacity

- Up to 20 packs/min

- Efficiency (%)

- High packing efficiency

- Connecting Type

- Electrical

- Condition

- New

- Material

- Mild Steel Body with Powder Coating

- Construction

- Robust heavy duty build

- Weight

- Approx. 250 kg

- Shape

- Rectangular

- Feature

- Automatic operation, Programmable controls, Photoelectric sensor, Adjustable conveyor speed, Shrink wrapping compatible

AUTOMATIC L-SEALER Trade Information

- Payment Terms

- Cash on Delivery (COD), Paypal, Western Union, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Delivery Time

- 1 MONTH Months

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- WOODEN BOX

- Main Export Market(s)

- Australia, South America, Middle East, Africa, Western Europe, Asia, Central America, Eastern Europe, North America

- Main Domestic Market

- All India

- Certifications

- AN ISO 9001:2015 CERTIFIED

About AUTOMATIC L-SEALER

AUTOMATIC L-SEALER: Competitive Edge & Versatile Applications

Gain a strong competitive advantage with the AUTOMATIC L-SEALER. Its user-friendly digital controls, adjustable conveyor speed, and pristine impulse wire cutting system deliver high efficiency for shrink packaging. Perfect for boxes, bottles, electronics, and stationeries, it fits seamlessly into industrial and commercial operations. Its excellent heavy-duty build ensures reliability in demanding settings, while programmable controllers and photoelectric sensors allow for customized, precise sealing of various packaging films such as PVC, POF, or polyolefin.

Delivery, Stock Readiness & Sampling: Seamless Processes

With stock ready for immediate valuation and quick dispatch, our offer includes pristine packaging of your AUTOMATIC L-SEALER to ensure it arrives in pristine condition. Delivery times are minimized to meet your business needs efficiently. For your convenience, sample units are available for evaluation, helping you make informed decisions. Our team is committed to prompt fulfillment and streamlined logistics for dealers, distributors, and manufacturers, ensuring smooth acquisition and excellent after-sales support.

FAQs of AUTOMATIC L-SEALER:

Q: How does the AUTOMATIC L-SEALER enhance packaging efficiency?

A: The AUTOMATIC L-SEALER features a digital PLC touch control system, adjustable conveyor speed, and fully automatic operation with a manual override, allowing quick, high-efficiency sealing and shrink packaging of up to 20 packs per minute.Q: What types of packaging films can be used with this machine?

A: This machine is compatible with PVC, POF, and polyolefin center-folded films, giving your operations flexibility based on packaging requirements.Q: When is the AUTOMATIC L-SEALER most beneficial?

A: It is most beneficial for industrial or commercial packaging, especially when you need consistent, high-volume shrink wrapping for boxes, bottles, electronics, and stationeries.Q: Where can the AUTOMATIC L-SEALER be installed or used?

A: The L-Sealer is designed for use in factories, warehouses, and packaging units by dealers, distributors, exporters, manufacturers, and suppliers throughout India.Q: What safety features are included in the machine?

A: Safety features include an emergency stop button, overload protection, and anti-accident protection to ensure safe operation during packaging processes.Q: How is the cleaning of the AUTOMATIC L-SEALER managed?

A: Cleaning is manual, allowing operators to easily maintain a pristine and hygienic working environment by regularly wiping the surfaces and inspecting working parts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PACKAGING AND LABELING MACHINES Category

LIQUID FILLING MACHINE

Pressure : Standard atmospheric

Capacity : 50 ml 1000 ml/filling cycle

Shape : Rectangular Base with Cylindrical Filling Nozzles

Efficiency (%) : ~98% dispensing accuracy

Connecting Type : Other, Nozzle Connection, Power Connection

Construction : Other, Robust, Industrial grade

AUTOMATIC CUP FILLING AND SEALING MACHINE

Pressure : Air pressure 68 bar required

Capacity : 1500 2400 cups/hour (model dependent)

Shape : Rectangular Base with Cup Carousels

Efficiency (%) : Up to 98%

Connecting Type : Other, Electric & pneumatic connections

Construction : Other, Robust and compact

VACUUM PACKING MACHINE(double Chamber)

Pressure : 0.1 MPa (Vacuum Pressure)

Capacity : 2040 Bags/Cycle depending on bag size

Shape : Rectangular

Efficiency (%) : 99%

Connecting Type : Other, Electric Connection, 3 Phase

Construction : Other, Robust Construction for Industrial Use

VACUUM PACKING MACHINE(Vertical Type)

Pressure : 0.1 to 0.09 MPa

Capacity : Sealing Width 500 mm / Chamber Size 500 x 500 x 80 mm

Shape : Vertical Rectangular

Efficiency (%) : 99%

Connecting Type : Other, Electrical Connection, Single/Three Phase

Construction : Other, Robust and Compact Design

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry