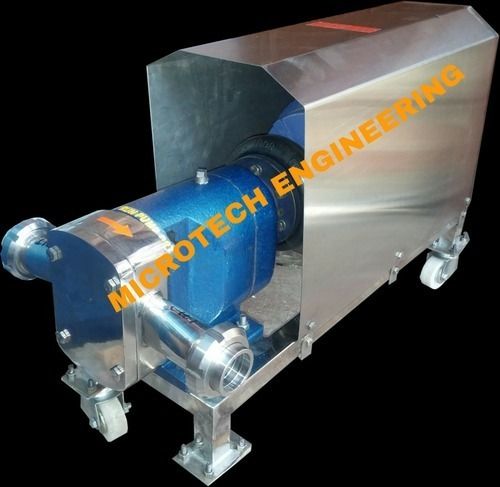

Essential Oil Pump

Essential Oil Pump Specification

- Working Temperature

- -10°C to 60°C

- Mounting Type

- Base Mounted

- Flow Rate

- 25 L/min

- Discharge Pressure

- 1.7 bar

- Features

- Corrosion Resistant, Low Maintenance

- Theory

- Centrifugal Pump

- Head Size

- 18 Meter

- Voltage

- 220V

- Noise Level

- <50 dB

- Max Suction

- 8 Meter

- Control System

- Manual

- Caliber

- DN15

- Inlet/Outlet

- 1/2 inch BSP

- Frequency

- 50 Hz

- Speed

- 2800 rpm

- Material

- Stainless Steel

- Structure

- Horizontal

- Power

- 0.37 kW

- Standard

- ISO 9001:2015

- Fuel Type

- Electric

- Pressure

- 1.8 bar

- Usage

- Essential Oil Transfer

- Application

- Industrial Essential Oil Extraction

- Suction Type

- Single Stage

- Seals Type

- Mechanical Seal

- Priming

- Self-priming

- Pump Type

- Centrifugal

- Capacity

- 1500 L/h

- Impeller Type

- Closed Impeller

- Motor Type

- Single Phase Induction

- Protection Grade

- IP55

- Cooling method

- Air Cooled

- Ambient Humidity

- ≤ 90%RH

- Weight

- 14 kg

- Service Life

- >5 years

Essential Oil Pump Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Letter of Credit (L/C), Telegraphic Transfer (T/T), Paypal, Western Union, Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Asia, Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Essential Oil Pump

Essential Oil Pump

Microtech engineering Lobe pumps are used in a variety of industries including, pulp and paper, chemical, food, beverage, Pharmaceutical, and biotechnology. They are popular in these Diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics.These pumps offer a variety of lobe options including single, biwing, tri-lobe (shown), and multi-lobe.Rotary lobe pumps are Non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self- priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous.

How Lobe Pumps Work Liquid flows into the cavity and is trapped by the lobes as they rotate.Lobe pumps are similar to external gear pumps in operation in that fluid flows around the interior of the casing. Unlike external gear pumps, however, the lobes do not make contact. Lobe contact is prevented by external timing gears located in the gearbox. Pump shaft support bearings are located in the gearbox, and since the bearings are out of the pumped liquid, pressure is limited by bearing location and shaft deflection.

- As the lobes come out of mesh, they create expanding volume on the inlet side of thepump

- Liquid travels around the interior of the casing in the pockets between the lobesand the casing it does not pass between the lobes.

- Finally, the meshing of the lobes forces liquid through the outlet port under pressure.Lobe pumps are frequently used in food applications because they handle solids without damaging the product. Particle size pumped can be much larger in lobe pumps than in other Positive Displacement Pump types. Since the lobes do not make contact, and clearances are not as close as in other Positive Displacement Pump, this design handles low viscosity liquids with diminished performance. Loading characteristics are not as good as other designs, and suction ability is low. High-viscosity liquids require reduced speeds to achieve satisfactory performance. Reductions of 25% of rated speed and lower are common with high-viscosity liquids.

Application Alcohol - Apple puree “ Apricots - Baby food“ Batter “ Beans “ Beer Beetroot - Biscuit Cream “ Blackcurrants“ Brine “Broth -Butter fat Caramel - Castor Oil - Cat food - Cheese curd - Cheese whey “ Cherries - Chicken paste - Chili con“ Carn“Chocolate “ Chutney “ Cockles - Coconut oil - Cod oil“ Coffee “liquor “ Cordials -Corn oil- Corn syrup“ Cottage “ cheese - Cotton seed “ oil “Cranberry - juice - Cream“ Creamcheese “ Custard - Dog food “ Dough “ Eggs “ whole - Egg yolk “ Essences “ Evaporated “milk -Fish “Flavorings - Fondants-Fruit juice - Fruit pulp - Fruit whole “Fruit -yogurt- Gelatin “ Gherkins“ Glucose Glycerin “ Gooseberries “ Gravy -- - Hand cream “ Honey “ Horseradish - Ice cream “Icings - Iodine - ointment etc

Efficient Essential Oil Transfer

This pump is engineered for seamless essential oil extraction and transfer, ensuring a steady flow of up to 1500 L/h. Its self-priming, single-stage centrifugal design makes it ideal for demanding industrial applications, helping users achieve reliable performance with minimal oversight.

Reliability and Longevity

Constructed from corrosion-resistant stainless steel and fitted with a durable mechanical seal, the pump promises a service life of over 5 years. Its IP55-rated motor and air cooling system enhance operational safety and reliability, even in environments with up to 90% ambient humidity.

Low Maintenance Operation

Thanks to its mechanical seal and efficient design, the Essential Oil Pump requires very little maintenance. This not only reduces downtime but also helps manage operational costs, making it a practical choice for manufacturers, exporters, and other industrial users.

FAQ's of Essential Oil Pump:

Q: How does the Essential Oil Pump operate for extracting and transferring oils?

A: The pump utilizes centrifugal force generated by its closed impeller to move essential oils efficiently. With self-priming capability, it can begin pumping automatically after initial setup, ensuring consistent transfer even when dealing with varying liquid levels.Q: What are the main benefits of using a stainless steel, corrosion-resistant pump in essential oil processing?

A: Stainless steel construction provides excellent resistance to corrosive substances typically found in essential oils, ensuring the pump maintains performance and structural integrity over long periods. This leads to less frequent replacement and consistent product quality.Q: When is it suitable to use this pump in industrial essential oil extraction?

A: This pump is ideal for use throughout the entire extraction and transfer process, especially where rapid, contamination-free movement of oils is needed. Its durable design and compliance with ISO 9001:2015 standards make it suitable for continuous and heavy-duty industrial operation.Q: Where can the Essential Oil Pump be installed, and what mounting type does it require?

A: The pump is base-mounted, making it suitable for installation in fixed locations within an extraction facility or processing plant. Its horizontal structure provides stability and allows for integration with existing pipelines and systems.Q: What is the process for maintaining the Essential Oil Pump to ensure long service life?

A: Routine checks should be performed to ensure the mechanical seal is intact and the motor is free of debris. Its low-maintenance design means periodic inspections and occasional cleaning are usually sufficient to guarantee reliable operation for more than five years.Q: How does the pump perform under various environmental conditions?

A: With an IP55 protection grade and air-cooled motor, the pump reliably operates in ambient humidity up to 90% and temperatures from -10C to 60C. These features support stable operation in diverse microclimates, typical of industrial extraction facilities in India.Q: What advantages does the self-priming feature provide during essential oil transfer?

A: Self-priming empowers the pump to begin working automatically without manual intervention after initial priming. This increases operational efficiency, minimizes the risk of air locks, and ensures uninterrupted essential oil flow, even after periods of shutdown.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lobe Pump Category

Positive Rotary Lobe Pumps

Minimum Order Quantity : 01

Material : SS304 / SS316

Pressure : Other, Up to 10 Bar

Usage : Other, Food, Pharmaceutical, Chemical, Cosmetic, Dairy, Beverage Processing

Fuel Type : Other, Electric

Cheese Transfer Pump

Material : Stainless Steel 304 / 316

Pressure : Other, Max 4 Bar

Usage : Other, Cheese Curd/Chunk Transfer

Fuel Type : Other, Electric

Ointment Transfer Pump

Material : Stainless Steel (SS316/SS304)

Pressure : Other, Up to 3 bar

Usage : Other, Industrial Fluid Transfer

Fuel Type : Other, Electric

Positive Rotary Lobe Pumps manufacturers in india

Price 65280.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : stainless steel

Pressure : Medium Pressure

Usage : Food, Water, Oil Well, Water Well, Boat, Cosmetics, Automobile, Air Pump, Other, Paper Printer

Fuel Type : Gasoline

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry