Call: 08071931448

Dough Feeding System

Dough Feeding System Specification

- Phase

- Three Phase

- Speed Mode

- Variable Speed Control

- Power Source

- Electric

- Automation Grade

- Fully Automatic

- Frequency

- 50/60 Hz

- Features

- Corrosion Resistant, Compact Design, User Friendly

- Function Type

- Feeding / Dosing

- Machine Type

- Food Processing Equipment

- Operating Temperature

- Up to 45C

- Feeding System

- Continuous Belt Feeding

- Noise Level

- < 70 dB

- Product Type

- Dough Feeding System

- General Use

- Industrial Bakery & Confectionery

- Material

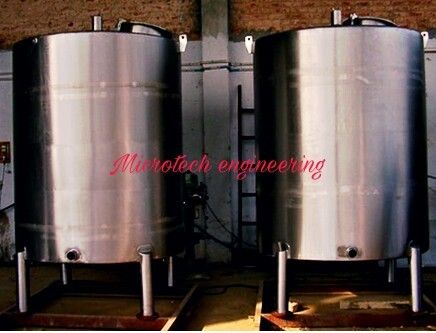

- Stainless Steel

- Type

- Automatic Feeding System

- Capacity

- 300-1500 kg/hr

- Weight (kg)

- 350 kg (Approx.)

- Product Shape

- Rectangular

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC (Programmable Logic Controller)

- Installation Type

- Floor Mounted

- Voltage

- 220-440 V

- Power

- 5 kW

- Dimension (L*W*H)

- Customized as per requirement

- Raw Material

- SS304 Stainless Steel

- Feature

- High Efficiency, Continuous Feeding, Easy Maintenance

- Color

- Silver

- Operator Panel

- Touchscreen HMI

- Finish Type

- Mirror Polished

- Safety Feature

- Emergency stop, Protective covers, Overload protection

- Input Hopper Capacity

- 120-250 kg

- Construction

- Fully welded frame with smooth surface finish for hygiene

- Cleaning

- Designed for easy dismantling and CIP

- Ambient Working Conditions

- 5°C to 45°C

- Installation Service

- Available on request

- Motor Type

- Heavy Duty Induction Motor

- Lubrication

- Centralized automatic lubrication system

- Mobility

- Optional castor wheels available

- Conveyor Belt Type

- Food Grade PU or PVC

- Compliance

- Meets international food safety standards

Dough Feeding System Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Telegraphic Transfer (T/T), Western Union, Paypal, Letter of Credit (L/C), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, Eastern Europe, Western Europe, Middle East, Central America, South America, Asia, North America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Dough Feeding System

Experience sensational savings with our lustrous Dough Feeding Systemyour last chance to revolutionize food production! Crafted with a potent, fully welded SS304 frame and mirror-polished finish for uncompromising hygiene, this high-efficiency system ensures continuous, automated feeding for industrial bakeries and confectioneries. Advanced safety features, touchscreen HMI, CIP-friendly dismantling, and variable-speed food-grade conveyor make operation user friendly and expedient. The robust induction motor handles up to 1500 kg/hr. Get it now and elevate your process with state-of-the-art automation and exceptional reliability!

Dough Feeding System: Versatile Plant Integration

This fully automatic Dough Feeding System is expertly engineered for use in large-scale bakery and confectionery plants across various sectors. Its computerized, PLC-controlled operation ensures precision and high throughput, making it ideal for industrial food production lines. Used for consistent continuous dough dosing, its robust design supports mixing, feeding, and dosing processes, while seamless integration with existing lines maximizes productivity and process flow.

Streamlined Delivery & Market Accessibility

Our Dough Feeding System is available across India, serving dealers, distributors, manufacturers, and more. With an efficient logistics strategy, we ensure prompt order completion, minimizing unnecessary expenditure while meeting supply demands. Flexible supply ability guarantees consistent availability, and customized delivery times accommodate plant schedules. Whether you need a single system or bulk purchases, our streamlined processes make fulfilling your order hassle-free, ensuring you stay ahead in your production goals.

Dough Feeding System: Versatile Plant Integration

This fully automatic Dough Feeding System is expertly engineered for use in large-scale bakery and confectionery plants across various sectors. Its computerized, PLC-controlled operation ensures precision and high throughput, making it ideal for industrial food production lines. Used for consistent continuous dough dosing, its robust design supports mixing, feeding, and dosing processes, while seamless integration with existing lines maximizes productivity and process flow.

Streamlined Delivery & Market Accessibility

Our Dough Feeding System is available across India, serving dealers, distributors, manufacturers, and more. With an efficient logistics strategy, we ensure prompt order completion, minimizing unnecessary expenditure while meeting supply demands. Flexible supply ability guarantees consistent availability, and customized delivery times accommodate plant schedules. Whether you need a single system or bulk purchases, our streamlined processes make fulfilling your order hassle-free, ensuring you stay ahead in your production goals.

FAQs of Dough Feeding System:

Q: How does the Dough Feeding System improve industrial bakery efficiency?

A: The systems fully automatic, continuous feeding design streamlines dough input, minimizes downtime, and ensures consistent quality, resulting in higher productivity and optimized process flow.Q: What materials and finishes are used for the Dough Feeding System?

A: It is constructed from corrosion-resistant SS304 stainless steel with a mirror-polished, smooth finish to meet stringent hygiene requirements and facilitate easy cleaning.Q: When can I expect my order to be delivered after purchase?

A: Delivery times are tailored to your order requirements and location, ensuring timely logistics and smooth order completion without unnecessary delays.Q: Where can the Dough Feeding System be installed?

A: Designed for floor mounting, it integrates seamlessly into a wide range of bakery and confectionery plant layouts, supporting customized dimensions as per project needs.Q: What makes cleaning and maintenance of this system user-friendly?

A: The system allows for easy dismantling and is CIP-ready, with a centralized automatic lubrication system, reducing maintenance effort and downtimes.Q: How does the control system enhance operational reliability?

A: A programmable logic controller (PLC) and touchscreen HMI provide intuitive, centralized control over all operations, allowing for efficient monitoring, variable speed control, and rapid troubleshooting.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Food Processing Machinery Category

DOUGH DIVIDER & ROUNDER

Voltage : 220 V

Type : Other, Divider and Rounder

Features : Consistent Product Quality

Power : 1.5 kW

Raw Material : Other, Flour

Function Type : Mixing Other, Dividing and Rounding

PROOFER

Voltage : 220240 V

Type : Other, Dough Proofer

Features : Uniform Steam Distribution, Stainless Steel Construction, Low Maintenance

Power : 1.5 kW

Raw Material : Other, Stainless Steel

Function Type : Mixing Other, Fermentation

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry