Cream Transfer Pump

Cream Transfer Pump Specification

- Speed

- 2800 RPM

- Inlet/Outlet

- 25mm/25mm

- Discharge Pressure

- 2 bar

- Flow Rate

- 1500 LPH

- Voltage

- 220-240V

- Noise Level

- Low

- Frequency

- 50/60 Hz

- Control System

- Manual

- Max Suction

- 5 Meter

- Caliber

- 25mm

- Theory

- Centrifugal Pump

- Features

- Corrosion Resistant, Easy to Clean, CIP Compatible

- Working Temperature

- 0C to 90C

- Head Size

- 20 Meter

- Mounting Type

- Base Mounted

- Material

- Stainless Steel (SS 304/316)

- Structure

- Single Stage

- Power

- 1 HP

- Standard

- ISO 9001 Certified

- Fuel Type

- Electric

- Pressure

- 2 bar

- Usage

- Cream Transfer, Dairy, Food Processing

- Application

- Dairy, Food Industry, Cosmetic Production

- Suction Type

- Positive Suction

- Seals Type

- Mechanical Seal

- Priming

- Self Priming

- Pump Type

- Sanitary Centrifugal Pump

- Capacity

- 1500 Litres/Hour

Cream Transfer Pump Trade Information

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 200 Per Year

- Delivery Time

- 200 Years

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- WOODEN CHARGE

- Main Export Market(s)

- Australia, Central America, North America, Eastern Europe, Middle East, Western Europe, South America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2008 MSME

About Cream Transfer Pump

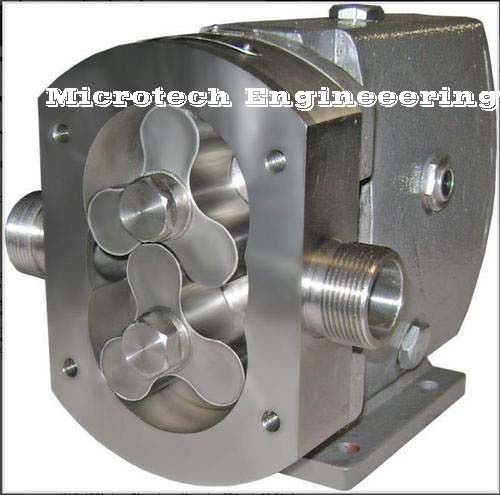

CREAM TRANSFER PUMP

We are one-step ahead of our competitors in manufacturing and wholesaling a wide range of Jaketed Stainless Steel CREAM Lobe Pumps. These find their wide application in various industries including food processing, beverages, dairy, pharmaceutical and many other allied industries. ergonomic design of these pumps reflect the hard labor and long research work of our experienced engineers. Besides, these pumps also ensure easy installation, corrosion resistance and long functional efficiency.

Specifications:

- As the rotors start to rotate, an expanding cavity is formed by rotation of the lobes which creates a vacuum at the inlet port, drawing liquid in pumping chamber.

- The product liquid is carried between the lobes and positively displaced, thereby sealing itself against the internal faces of the pump casing.

- The other lobe chamber is filed with the product liquid and about to commence it's discharge cycle.

- Finally the product liquid is forced or pressed out of discharge port of the pump in continuous smooth flow and pressure generated by the meshing of the lobe rotors

MICROTECH ENGINERING Lobe pumps are used in a variety of industries including, pulp and paper, chemical, food, beverage, Pharmaceutical, and biotechnology. They are popular in these Diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics.These pumps offer a variety of lobe options including single, biwing, tri-lobe (shown), and multi-lobe.Rotary lobe pumps are Non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self- priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous.

How Lobe Pumps Work Liquid flows into the cavity and is trapped by the lobes as they rotate.

Lobe pumps are similar to external gear pumps in operation in that fluid flows around the interior of the casing. Unlike external gear pumps, however, the lobes do not make contact. Lobe contact is prevented by external timinggears located in the gearbox. Pump shaft support bearings are located in the gearbox, and since the bearings are out of the pumped liquid, pressure is limited by bearing location and shaft deflection.

Advantages

- Pass medium solids

- No metal-to-metal contact

- Superior CIP/SIP capabilities

- Long term dry run (with lubrication to seals)

- Non-pulsating discharge

Disadvantages

- Requires timing gears

- Requires two seals

- Reduced lift with thin

Effortless Fluid Handling for Diverse Industries

Engineered for the dairy, food, and cosmetic sectors, this sanitary centrifugal pump facilitates smooth cream transfer. Its centrifugal theory, combined with a positive suction feature, ensures efficient and consistent fluid movement, even in challenging processing conditions.

Robust Construction Meets Hygiene Standards

Constructed from high-grade SS 304/316 and equipped with a food-grade silicone gasket, the pump delivers superior corrosion resistance and easy-to-clean surfaces. The mirror polish finish and CIP compatibility make maintenance straightforward while preserving product purity.

Mobility and Operational Versatility

Portability is achieved through a sturdy trolley-mounted design, making relocation between workstations hassle-free. Supporting both tri-clamp and threaded connection types, the pump fits seamlessly into various setups, with manual controls offering operational flexibility.

FAQs of Cream Transfer Pump:

Q: How is the Cream Transfer Pump moved within the workspace?

A: The pump features a trolley-mounted design, enabling easy movement between locations. Its compact and base-mounted structure ensures stability during operation and portability across dairy, food, or cosmetic production facilities.Q: What hygienic benefits does the mirror polish surface offer?

A: The mirror polish finish minimizes product adherence and supports easy cleaning. This smooth surface, alongside the CIP compatibility, ensures sanitary handling suitable for sensitive food and cosmetic applications.Q: When should I use the open or closed impeller option?

A: Open impellers are ideal for high-viscosity products and applications requiring unobstructed flow, while closed impellers provide better efficiency for lower viscosity fluids. Select the impeller type based on your specific process fluid requirements.Q: Where is the pump suitable for installation and use?

A: This pump is designed for use in dairy operations, food processing plants, and cosmetic production environments. Its compact structure and trolley mobility make it practical for factories throughout India, especially where regular relocation is needed.Q: What process does the pump use for cream transfer?

A: Utilizing the centrifugal pump theory, the machine generates flow by converting rotational energy into fluid movement. Its self-priming ability and positive suction facilitate stable transfers of cream and viscous products up to 3000 cP.Q: How does the pump ensure safe and efficient operation?

A: Equipped with an IP55-rated enclosure and mechanical seals, the pump guards against dust and moisture, increasing operational reliability. The food-grade silicone gasket and stainless steel construction further ensure product safety and easy maintenance.Q: What are the main usage and benefits of the pump in industry?

A: The pumps high flow rate, self-priming capability, sanitary design, and energy-efficient motor deliver optimized performance for cream, dairy, and food processing. Its corrosion-resistant build and manual controls offer durability and flexible operation for manufacturers, suppliers, and exporters.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lobe Pump Category

BUMP LOBE PUMP

Minimum Order Quantity : 01 Piece

Pump Type : Other, Positive Displacement

Pressure : Other, 0.5 to 8 Bar

Features : Hygienic design, Easy Clean, CIP/SIP compatible, Low Shear Handling

Usage : Other, Industrial; Chemical, Food Processing, Dairy

Material : Stainless Steel (SS304, SS316) / Cast Iron

Syrup Transfer Pump

Minimum Order Quantity : 01

Pump Type : Other, Sanitary Pump

Pressure : Other, Low to Medium

Features : Hygienic design, Easy to Clean, Corrosion Resistant

Usage : Other, Syrup Transfer / Food Industry

Material : Stainless Steel (SS 304/316)

Horizontal Lobe Pump

Minimum Order Quantity : 01

Pump Type : Other, Horizontal Lobe Pump

Pressure : Other, Max 1.2 MPa

Features : CIP/SIP compatible, Hygienic Design, Reversible Flow, Easy Maintenance, Low Shear Pumping

Usage : Other, Industrial, Food Processing, Dairy, Beverage, Pharma

Material : Stainless Steel 304/316, Cast Iron

Thick Liquid Transfer Pump

Minimum Order Quantity : 01

Pump Type : Other, Thick Liquid Transfer Pump

Pressure : Other, Up to 4 Bar

Features : Corrosionresistant, Easy to clean, High Viscosity Handling

Usage : Other, Industrial, Chemical, Food Processing

Material : Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry