Call: 08071931448

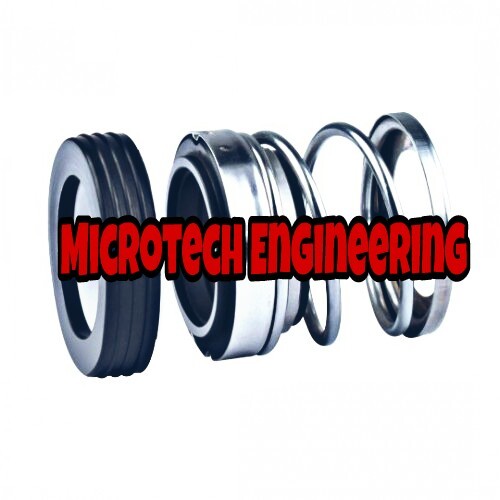

Cartridge Seal

MOQ : 01 Piece

Cartridge Seal Specification

- Theory

- Mechanical seal theory - interference and barrier fluid

- Application

- Pumps, Compressors, Mixers, Reactors

- Hardness

- Seal faces: 85-92 HRA

- Style

- Cartridge type, single & double

- Material

- SS316, Carbon, Ceramic, Viton

- Temperature

- -20C to +220C

- Pressure

- Upto 25 bar

- Speed

- Upto 3000 RPM

- Function

- To prevent fluid leakage in rotating equipment

- Size

- Shaft diameter: 25 mm to 100 mm

- Structure

- Pre-assembled balanced design

- Corrosion Resistance

- High for all process fluids

- Lubrication

- Buffer & barrier fluid compatibility

- Flange Material

- SS316

- Leakproof Design

- Double O-ring sealing

- O-Ring Material

- Viton/EPDM

- Surface Finish

- Seal face: lapped to 2 microns

- Axial Movement Compensation

- Yes

- Shaft Tolerance

- +0/-0.05 mm

- Seal Face Combination

- Carbon vs. Ceramic, SiC vs. SiC, Tungsten Carbide

- Elastomer Material

- Viton, EPDM, FKM

- Mounting Type

- Direct mounted

- Rotational Direction

- Independent

- Spring Type

- Multi-spring

Cartridge Seal Trade Information

- Minimum Order Quantity

- 01 Piece

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Pieces Per Year

- Delivery Time

- 100 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- WOODEN CHARGE

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2008 MSME

About Cartridge Seal

Cartridge Seal

Single cartridge seal, SUITABLE For petro CHEMICAL chemistry and paper making,medical industry.mechanical seal manufacture . is the advanced designer & manufacturer of mechanical seal, the range involves in: industrial pump mechanical seal, mixer and agitator seal, cartridge seal, metal bellows seal, auto cooling pump seal and auto air-condition compressor lip seal.

Reliable Performance with Advanced Seal Faces

Our cartridge seals utilize combinations such as Carbon vs. Ceramic, SiC vs. SiC, and Tungsten Carbide, offering excellent wear resistance and high strength. The seal faces are lapped to a fine 2-micron finish, ensuring minimal leakage and longevity even in demanding conditions. Multiple elastomer options (Viton, EPDM, FKM) enhance chemical resistance, making these seals highly suitable for various process fluids.

Engineered for Safety and Versatility

Direct mounting, a double O-ring sealing system, and a pre-assembled balanced construction contribute to simpler installation and leak-proof performance. Designed with multi-spring arrangements and axial movement compensation, these seals adapt to operational variations and provide consistent sealing, ensuring safety and efficiency across a wide range of industrial applications.

FAQs of Cartridge Seal:

Q: How does the cartridge seal handle different rotational speeds and pressures?

A: The cartridge seal is designed to operate at speeds up to 3000 RPM and pressures up to 25 bar. Its balanced design and multi-spring setup distribute loads evenly, maintaining effective sealing and durability even under variable operational conditions.Q: What material options are available for the seal face and elastomers, and when should each be used?

A: Seal face combinations include Carbon vs. Ceramic, SiC vs. SiC, and Tungsten Carbide, offering different levels of hardness and chemical compatibility. Elastomer choices include Viton, EPDM, and FKM, selected based on process fluid compatibility and operating temperature. Consult the chemical compatibility chart to choose the most appropriate materials for your application.Q: Where can this cartridge seal be installed, and by whom?

A: These cartridge seals are suitable for pumps, compressors, mixers, and reactors across various industries. As a pre-assembled, direct-mounted product, installation is simplified and can be performed by trained maintenance personnel at manufacturer, supplier, or end-user sites throughout India.Q: What are the main benefits of using a double O-ring sealing design?

A: A double O-ring sealing configuration enhances leak prevention and resilience against pressure fluctuations. It provides an additional sealing layer, ensuring fluid containment even if one O-ring experiences wear or degradation.Q: How does the seal accommodate axial movement and shaft misalignment?

A: The balanced, pre-assembled cartridge design and multi-spring arrangement provide axial movement compensation. This allows the seal to adapt to minor shaft misalignments or axial shifts, maintaining optimal seal face contact and performance.Q: What is the recommended process for maintaining the seals performance over time?

A: Regularly inspect the seal faces, O-rings, and springs for wear or damage during routine maintenance. Ensure buffer or barrier fluids are used as required and within recommended specifications. Follow the manufacturers guidelines for safe disassembly, inspection, and reassembly to prolong the seals lifespan.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry