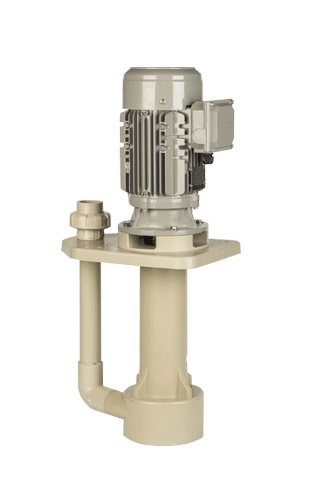

Vertical Chemical Pumps

Vertical Chemical Pumps Specification

- Caliber

- DN25 - DN50

- Theory

- Centrifugal Pump

- Noise Level

- 70 dB

- Inlet/Outlet

- 32 mm / 25 mm

- Working Temperature

- -20C to 100C

- Speed

- 2850 rpm

- Voltage

- 220V/380V

- Frequency

- 50Hz/60Hz

- Features

- Corrosion Resistant, Leak Proof Design, Easy Maintenance

- Discharge Pressure

- 0.2-0.35 Mpa

- Flow Rate

- 3-35 m/h

- Head Size

- 5-35 m

- Control System

- Manual/Automatic

- Mounting Type

- Baseplate Mounted

- Max Suction

- 6 m

- Material

- Polypropylene (PP), PVDF, Stainless Steel

- Structure

- Single-stage

- Power

- 0.75 kW - 7.5 kW

- Standard

- ISO 2858

- Fuel Type

- Electric

- Pressure

- Up to 3.5 bar

- Usage

- Chemical Handling

- Application

- Acids, Alkalis, Corrosive Liquids

- Suction Type

- Vertical

- Seals Type

- Mechanical Seal

- Priming

- Self-Priming

- Pump Type

- Vertical Chemical Pump

- Capacity

- Customizable

- Motor Brand

- Siemens/ABB/Equivalent

- Max Solid Passage

- 8 mm

- Impeller Type

- Closed/ Semi-Open

- Pump Length

- 500mm - 2000mm

- Cooling Method

- Air Cooled

- Protection Class

- IP55

- Color

- Blue / Customizable

- Operation Mode

- Continuous/Intermittent

- Service Life

- >10,000 hours

- Installation Height

- Up to 4 meters above liquid level

- Shaft Material

- SS304/SS316/PTFE Coated

Vertical Chemical Pumps Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Western Union, Paypal, Cash Against Delivery (CAD), Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Vertical Chemical Pumps

Our highly skillful experts using the top quality raw material at par with the industry prevalent standards manufacture these products. Moreover, to preserve the quality, ourquality analyst checks the quality on a variety of parameters of industry.Features:Standard designsPrecision engineeredPurpose specificEfficient & Dependable ForAcids Caustic Plating solutionEffluent treatmentWaste water treatmentDetails:Flow up to 18 m3/hrHead up to 20 mtrsS S cantilever shaft protected by heavy walled Polypropylene SleeveHeavy duty cast iron motor support with ball bearing separations pump shaft and motor shaftRugged glass filled polypropylene Impeller for long lifeStandard available submersible length:250 mm500 mm

Exceptional Chemical Resistance

Crafted from materials like polypropylene, PVDF, and stainless steel, these vertical chemical pumps are highly resistant to corrosion, making them ideal for transferring aggressive acids, alkalis, and a broad spectrum of corrosive chemicals. The shaft design further enhances reliability, while the mechanical seal ensures a leak-proof operation, reducing potential hazards in industrial applications.

Customizable for Diverse Applications

Available in pump lengths ranging from 500mm to 2000mm and customizable colors, these pumps are versatile in installation and appearance. They accommodate various flow rates, head requirements, and offer different mounting and control options to suit continuous or intermittent operations. This flexibility supports a large number of industries, from pharmaceutical to chemical processing.

Efficient, Low-Noise Performance

Powered by top-tier motors from Siemens or ABB and air cooled, these pumps maintain noise levels at or below 70 dB. Their self-priming, single-stage centrifugal design delivers efficient, continuous performance. With a service life exceeding 10,000 hours and minimal maintenance requirements, they ensure reliable operation and cost savings over time.

FAQ's of Vertical Chemical Pumps:

Q: How do vertical chemical pumps ensure safe handling of corrosive liquids?

A: Vertical chemical pumps are constructed using corrosion-resistant materials such as polypropylene, PVDF, and stainless steel (SS304 or SS316), combined with PTFE-coated shafts and mechanical seals. This design prevents leaks and ensures the safe transfer of aggressive acids, alkalis, and corrosive chemicals.Q: What is the installation process for these pumps and where can they be mounted?

A: These pumps are designed for baseplate-mounted installation, allowing them to be positioned up to 4 meters above the liquid level. The vertical suction configuration and self-priming capability simplify setup and ensure reliable operation even when the pump is not submerged.Q: When is it advisable to use a vertical chemical pump over other types?

A: Vertical chemical pumps are ideal when there is a need to handle corrosive liquids from tanks or pits where the pump must be positioned above the liquid level. Their design mitigates the risk of leakage, minimizes contamination, and allows efficient operation for both continuous and intermittent chemical transfer processes.Q: What is the process for maintaining these vertical chemical pumps?

A: Maintenance is straightforward due to their easy-access construction. Regular inspections for wear on the impeller, seals, and shaft are recommended. The air-cooled motor, leak-proof design, and high-quality materials reduce the frequency and complexity of maintenance, helping to extend the service life beyond 10,000 hours.Q: How can users benefit from the customizable options offered?

A: Users can select pump length, shaft and construction materials, and even custom colors to best suit their operational environment and chemical compatibility requirements. This adaptability ensures optimal performance, maximized lifespan, and aesthetic integration into existing systems.Q: What protection features are included in these pumps?

A: These chemical pumps are equipped with IP55-rated protection against dust and water ingress, as well as durable mechanical seals to prevent leaks. The combination of robust construction and reliable sealing offers enhanced safety for industrial chemical transfer applications.Q: What range of operating conditions can these pumps handle?

A: With a working temperature range from -20C to 100C, flow rates of 3-35 m3/h, a maximum head of 35 meters, max suction up to 6 meters, and support for both 50Hz and 60Hz frequencies, these pumps are suitable for a variety of demanding industrial environments across India and beyond.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PP Chemical Pump Category

Ice Cream Transfer Pump

Minimum Order Quantity : 01 Piece

Usage : Other, Ice Cream Transfer, Food Processing

Features : CIP/SIP Compatible, Easy Cleaning, Hygienic, Compact Design

Pressure : Other, Max 8 Bar

Material : Stainless Steel (SS316/SS304)

Pump Type : Other, Lobe Pump

PP Chemical Process Pump

Minimum Order Quantity : 01

Usage : Other, Chemical Processing, Acid Handling, Electroplating, Effluent Treatment

Features : Corrosion Resistant, Leak Proof, Easy Maintenance

Pressure : Other, Up to 3.5 kg/cm

Material : Polypropylene (PP)

Pump Type : Other, Chemical Process Pump

Scrubber Liquid Transfer Pump

Usage : Other, Industrial Scrubber liquid transfer

Features : Corrosion resistant, efficient operation, suitable for chemicals

Pressure : Other, 2.4 kg/cm

Material : PP (Polypropylene) / FRP

Pump Type : Other, Centrifugal Pump

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry