Sanitary Filter Pump

Sanitary Filter Pump Specification

- Caliber

- DN32 to DN65

- Flow Rate

- 3-25 m/h

- Speed

- 2900rpm/1450rpm

- Head Size

- 8-35 meters

- Working Temperature

- -10C to 120C

- Noise Level

- 75 dB

- Inlet/Outlet

- 1.5 / 1.5

- Mounting Type

- Horizontal

- Control System

- Manual / Automatic

- Voltage

- 220V/380V

- Frequency

- 50Hz/60Hz

- Discharge Pressure

- Up to 4 bar

- Max Suction

- 7 meters

- Theory

- Centrifugal Pump

- Features

- Hygienic design, Easy maintenance, CIP compatible

- Material

- Stainless Steel 304/316L

- Structure

- Single Stage

- Power

- 0.75KW to 7.5KW

- Standard

- 3A, DIN, SMS, ISO

- Fuel Type

- Electric

- Pressure

- Up to 4 bar

- Usage

- Liquid Filtration

- Application

- Food, Beverage, Dairy, Pharmacy

- Suction Type

- End Suction

- Seals Type

- Mechanical Seal

- Priming

- Self-priming optional

- Pump Type

- Sanitary Filter Pump

- Capacity

- 3-25 m/h

- Protection Class

- IP55/IP65

- Surface Finish

- Electropolished Ra 0.6m

- Motor Type

- Asynchronous Motor

- Direction of Rotation

- Clockwise (standard)

- Impeller Type

- Closed Impeller

- Weight

- 35kg to 120kg

- Phase

- Single/Three Phase

- Ambient Temperature

- -15C to +40C

- Connection Ends

- Clamp / Threaded / Flanged

- Seal Material

- EPDM, FPM or PTFE

- Maximum Viscosity

- 500 cps

Sanitary Filter Pump Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Paypal, Western Union, Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1000 Per Year

- Delivery Time

- 1 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

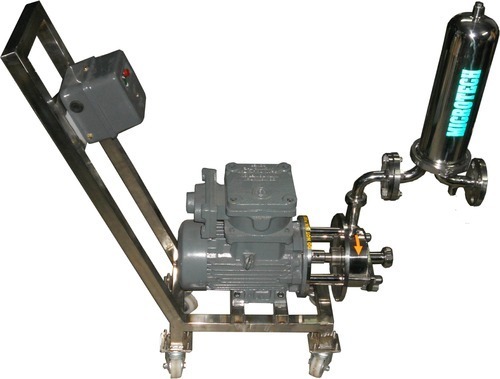

About Sanitary Filter Pump

- Sanitary Filter Pump

- Head : 48 meter

- Capacity : 33 m3/h

- Delivery size : 12mm to 65 mm

- Temperature : -10 to 95 degree Celsius

- Test pressure : 10 kg/cm2

Standard futures :

- Centrifugal single stage

- Flange as per din standard

- Back pull out design

- Open / close impeller

- Shaft sealing by single / doable mechanical seal

- Sealed grease lubricated , deep grove ball bearing

- He pump handle liquid having viscosities up to 1500 centrioles

- Also with flame proof motor

Optional futures :

- Shaft sealing by gland packing

- Bearing lubricating by oil

- ANSI drilling on DIN flanges

- Trolley mounting arrangement

- Various type of connection

Material :

- Casing : st. Steel ( cf8 / cf8m )

- Shaft : st. Steel ( ss 410 / ss 316 / ss 304 )

- Impeller : st. Steel ( ss 410 / ss 316 / ss 304 )

- Back Plate: st. Steel ( ss 410 / ss 316 / ss 304 )

- Mechanical Seal : TC/TC , SIC/SIC TEFLON/ GFT

- MOTOR COVER : SS 304 , SS 316

- GASKET : Viton / Nitrile/ Silicon / PTFE

- Colors dies & pigments / paints

- Descaling application

- Sagar industries

- Hot & cold water pumping

- Sparkling filter press

- Sugar syrup

- Chemical processing

- Application :

- Dairy industries

- Food processing plant

- Pharmaceutical industries

- Sugar & confectionery

- Bottling plants

- Distillery

- Beverages

- Water treatment plants

Hygienic Design for Sensitive Applications

This pump adheres to 3A, DIN, SMS, and ISO standards, making it ideal for sectors requiring stringent hygiene control, such as food, beverage, dairy, and pharmaceutical industries. Its electropolished surface minimizes contamination risk, while robust mechanical seals (EPDM, FPM, PTFE) provide leak protection even in demanding environments.

Flexible Mounting and Connection Options

Users can choose from clamp, threaded, or flanged ends to ensure seamless integration into various pipelines. The horizontal mounting design allows for stable installation, while process compatibility is enhanced by self-priming options and multiple inlet/outlet sizes (DN32 to DN65).

Reliable Performance with Easy Maintenance

Operating at either 1450rpm or 2900rpm under manual or automatic control, the pump supports single or three-phase voltage (220V/380V) and delivers quiet performance (75 dB). The design is optimized for quick cleaning and simple maintenance, supporting CIP procedures and promoting efficient production workflows.

FAQ's of Sanitary Filter Pump:

Q: How does the Sanitary Filter Pump ensure a hygienic operation in food and beverage applications?

A: The pump features an electropolished surface finish (Ra 0.6m) and is built from stainless steel 304/316L to prevent contamination and facilitate easy cleaning. It complies with international sanitary standards like 3A, DIN, SMS, and ISO, making it suitable for critical hygiene environments.Q: What types of mechanical seals are available, and how do they impact usage?

A: The pump supports EPDM, FPM, or PTFE mechanical seals, which offer excellent chemical resistance and longevity. These seal options ensure leak-proof performance across a wide range of liquids and temperatures, enhancing reliability in various industrial processes.Q: When is self-priming functionality recommended for this pump?

A: Self-priming is optional and recommended when the pump needs to handle suction from below ground or when the inlet is above the pump level. This feature provides greater flexibility in installation and operation, particularly in complex system layouts.Q: Where can this sanitary pump be installed, considering its mounting and ambient requirements?

A: The pump is designed for horizontal mounting and operates efficiently in environments with ambient temperatures ranging from -15C to +40C. Its IP55/IP65 protection class ensures suitability for indoor and moderately harsh industrial settings.Q: What is the maximum viscosity the pump can handle, and which liquids are typically filtered?

A: This pump manages liquids with viscosities up to 500 cps. It is typically used for filtering products such as milk, juices, pharmaceutical solutions, and other food-grade or high-purity liquids.Q: How does the closed impeller design benefit the filtration process?

A: A closed impeller ensures optimal flow efficiency and minimizes the risk of product contamination. It also supports high head and flow rates (up to 25 m3/h, 35 meters), making it ideal for demanding filtration applications.Q: What maintenance process is recommended for keeping this pump in optimal condition?

A: Regular cleaning and inspection according to the CIP (Clean-In-Place) procedure are advised. Maintenance is simplified due to its hygienic design and easy accessibility, preventing downtime and maximizing operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sanitary Pump Category

Sparkler Filter Pump

Minimum Order Quantity : 01

Material : Stainless Steel (SS304/316)

Pressure : Other, Max 5 kg/cm

Usage : Other, Liquid Filtration, Industrial Applications

Max Suction : Up to 4 meters

SS Hygienic Pump

Minimum Order Quantity : 01

Material : SS304 / SS316 Stainless Steel

Pressure : Other, Up to 6 Bar

Usage : Other, Food & Beverage, Pharmaceutical, Dairy, Chemical

Max Suction : Up to 8 meters

Sparkler Filter Press Pump

Price 16518.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : stainless steel

Pressure : Medium Pressure

Usage : Water, Water Well, Food, Boat, Automobile, Air Pump, Cosmetics, Other, Paper Printer, Oil Well

Max Suction : 150mm

Sanitary Filtration Pump

Price 15302.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : stainless steel

Pressure : Medium Pressure

Usage : Water, Oil Well, Water Well, Food, Boat, Other, Air Pump, Cosmetics

Max Suction : 150mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry