Pickle Making Plant

Pickle Making Plant Specification

- Phase

- Three Phase

- Speed Mode

- Variable Speed Options

- Features

- Corrosion Resistant, Durable, Easy to Clean

- Power Source

- Electric

- Operating Temperature

- Room Temperature to 120C

- Automation Grade

- Semi-Automatic to Automatic

- Frequency

- 50/60 Hz

- Feeding System

- Manual Hopper or Conveyor Feed

- Noise Level

- Low

- Machine Type

- Industrial Pickle Processing Machine

- Heating Method

- Steam/Electric Heating

- Function Type

- Mixing, Blending, Cutting, Packing

- Product Type

- Pickle Making Plant

- General Use

- For Commercial Pickle Production

- Material

- Stainless Steel

- Type

- Food Processing Plant

- Capacity

- 250 kg/hr to 2000 kg/hr

- Weight (kg)

- 1000 - 3500 kg (Varies as per capacity)

- Product Shape

- Rectangular Modular Plant

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- PLC Control Panel

- Installation Type

- Floor Mounted

- Voltage

- 220-440 V

- Power

- 2 - 15 kW (Depending on Size and Capacity)

- Dimension (L*W*H)

- Customizable / As per Requirement

- Raw Material

- SS304/SS316 Stainless Steel

- Feature

- Easy Operation, Hygienic Processing, Low Maintenance

- Color

- Metallic Silver (Stainless Steel Finish)

- Production Application

- Suitable for Mango, Mixed, Lemon, Chilli, and Other Pickles

- Lid Type

- Lockable Hinged Stainless Steel Lid

- Mixer Type

- Agitator, Paddle, or Screw

- Inlet/Outlet Diameter

- As per order specification

- Water Consumption

- Minimal, Eco-friendly Design

- Finishing

- Mirror Polished

- Spare Parts Support

- Available on Request

- Safety Features

- Emergency Stop Button, Overload Relay

- Transportability

- Movable with Wheels (Optional)

- Cleaning System

- CIP (Clean-In-Place) Compatible

Pickle Making Plant Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Supply Ability

- 100 Per Year

- Delivery Time

- 1 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Western Europe, Australia, Eastern Europe, Middle East, Central America, South America, Asia, North America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Pickle Making Plant

Stainless steel 2.High efficiency 3.Easy to operate Small Cucumber Processing Line ( also call: dill pickles, cornichon,gherkins in vinegar etc) A pickled cucumber (commonly known as a pickle in the United States and Canada or generically as gherkins Asia ) is a cucumberthat has been pickled in a brine, vinegar, or other solution and left to ferment for a period of time, by either immersing the cucumbers in an acidic solution or through souring by lacto-fermentation.

Made of stainless steel 304, our pickle mixer features U-Shape chamber with heavy duty rotation blades. These blades turn at a constant speed to mix the product inside. Provided with tilting drum for easy discharge of the mixed product. The compact unit is equipped and reduction gearbox.

Versatile Pickle Production

Engineered for a range of products such as mango, mixed, lemon, and chilli pickles, this modular plant accommodates various customizations in size, mixer type, and capacity. Its stainless steel construction ensures compliance with hygiene standards and enhances product quality, making it ideal for medium to large-scale commercial operations.

Advanced Automated Features

The plant operates with a PLC control panel for semi-automatic to automatic production, offering variable speed modes, safety mechanisms like emergency stop, and overload relay. The lockable hinged lid and CIP (Clean-In-Place) system facilitate safe, efficient, and thorough cleaning, streamlining production workflow with minimal manual intervention.

Sustainable and Efficient Operations

With a minimal water consumption and eco-friendly design, this system is conscious of operational costs and environmental impact. Its durability and easy-to-clean features further ensure low maintenance, while optional mobility on wheels allows relocation as needed for optimal floor space utilization.

FAQs of Pickle Making Plant:

Q: How does the Pickle Making Plant accommodate different types of pickles?

A: The plant is designed with modular construction and customizable mixer types (agitator, paddle, or screw), enabling efficient processing of mango, mixed, lemon, chilli, or other pickles while ensuring consistent results whether blending, mixing, or cutting ingredients.Q: What are the main benefits of using a semi-automatic or automatic pickle making plant?

A: This plant increases operational efficiency and product yield through automated mixing, cutting, and packing, maintains hygiene with a stainless steel build and CIP compatibility, reduces manual labor, and ensures better safety via emergency stop and overload protection.Q: When is it advisable to choose a floor-mounted, movable plant?

A: A floor-mounted installation ensures stability for large-scale production, while opting for wheels enhances transportability, making it suitable when plant mobility within the factory layout or between facilities is required.Q: Where can this Pickle Making Plant be installed and used?

A: Ideal for commercial production facilities, food processing units, and factories engaged in the fabrication, wholesale, or supply of pickles. It serves manufacturers, dealers, exporters, and other industry professionals across India.Q: What is the typical process involved in this plant?

A: The process starts with feeding raw materials through a manual hopper or conveyor. The ingredients are then mixed, blended, and cut using the selected mixer, heated via steam or electric method, and finally packed, all controlled via a PLC panel for efficiency.Q: How does the plant ensure hygienic processing and easy maintenance?

A: Hygiene is achieved through the use of SS304/SS316 stainless steel, a mirror finish, and the inclusion of a CIP (Clean-In-Place) system that simplifies thorough chemical or water-based cleaning without disassembly, resulting in low ongoing maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

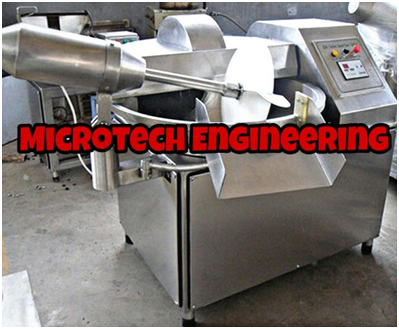

HAEVY DUTY BOWL CUTTER

Type : Other, Heavy Duty

Power : 3 kW

Product Type : Bowl Cutter

Voltage : 220240 V

General Use : Meat Processing

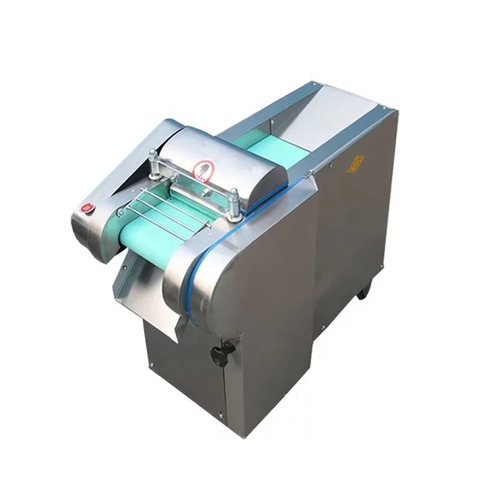

ELECTRIC OVEN

Minimum Order Quantity : 1 Piece

Type : Food Processors

Power : 3 Kw

Product Type : ELECTRIC OVEN

Voltage : 220 V

General Use : Restaurant

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry