PHE Plate Heat Exchangers

PHE Plate Heat Exchangers Specification

- Flow Rate

- Up to 250 m/hr (Based on Model)

- Connecting Type

- Flanged / Threaded

- Pressure

- Up to 25 bar

- Media Type

- Liquid, including Water, Oil, Chemicals

- Efficiency (%)

- Up to 95%

- Capacity

- Customized up to several MW

- Temperature Range

- -10C to 180C

- Cleaning Method

- Easy Plate Removal for Mechanical/Chemical Cleaning

- Condition

- New

- Material

- Stainless Steel / Titanium / Other Alloys

- Diameter

- Variable, based on design

- Construction

- Plate type, multi-pass

- Medium Filter

- Liquid / Fluid

- Weight

- Custom, depends on number of plates and size

- Shape

- Rectangular plate module

- Feature

- High thermal efficiency, compact design, easy to dismantle and clean, modular configuration, leak-proof construction

PHE Plate Heat Exchangers Trade Information

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 200 Per Year

- Delivery Time

- 200 Years

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- WOODEN BOX

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2008 MSME

About PHE Plate Heat Exchangers

PHE Plate Heat ExchangersMICROTECH ENGINEERING Our plate heat exchangers are widely used for heating, cooling, pasteurizing and heat recovery in hygienic and industrial applications including food and beverage industries, chemical, petrochemical, oil & gas, power, energy, other industrial sectors, and marine applications.

Materials:

- Plates: AISI 316, AISI 304, Titanium and most alloys

- Gaskets: NBR per, EPDM, FKM and others

- Frames: ms with ss cladding Stainless steel or painted Carbon steel

- Extensive range of plate options

- EnergySaver plates for superior heat transfer efficiency.

- DuraFlow plates for continuous process and run time.

- Easy Flow plates for media containing fibres or pulp, requiring highest possible recovery without blocking.

Duo Safety plates, when added security against intermixing is required.

* Compact and durable designs

* High efficiency due to full counter current flow

* Resistant to thermal stress

* Glue free gaskets

* Possibility of combining different gasket materials for cost effective solutions

* Easy to clean

Other Information

Minimum Order Quantity: 1 Square Meter(s)

Optimized Plate Technology

Our PHEs feature corrugated plates designed to maximize turbulence and heat transfer efficiency. This pattern ensures that energy exchange between liquids is both rapid and even, resulting in thermal efficiencies of up to 95%. The modular structure allows for flexibility in design, capacity, and easy future expansions.

Quality Materials and Customization

Choose from stainless steel, titanium, or other specialty alloys to suit challenging and corrosive environments. Our gasket materials, including EPDM, NBR, and Viton, are selected according to your application, ensuring safety and longevity. Plate configurations and unit capacity are fully customizable to match project-specific requirements.

Comprehensive Support and Service

We provide on-site technical assistance, streamlined installation, and prompt after-sales service throughout India. Our expert team assists with design selection, troubleshooting, and regular maintenance, ensuring your plate heat exchanger operates at peak efficiency.

FAQs of PHE Plate Heat Exchangers:

Q: How are the number of plates and heat transfer area determined for a PHE?

A: The number of plates, ranging from 10 to 400 per unit, and the heat transfer area (0.2120 m) are selected based on your process flow rates, required temperature change, and duty specifications. Our experts analyze your requirements and recommend optimal configurations for efficiency and cost-effectiveness.Q: What media types and industries can these plate heat exchangers be used for?

A: These PHEs are suitable for various liquid media including water, oils, and chemicals, making them ideal for HVAC, dairy, pharmaceutical, chemical, power, marine, and oil & gas applications. The units material options and gasketing ensure compatibility with diverse fluids and operating conditions.Q: When is it necessary to choose different gasket materials like EPDM, NBR, or Viton?

A: Gasket material selection depends on the type of medium, operating temperature, and chemical compatibility. EPDM suits water-based processes, NBR is preferred for oils and hydrocarbons, while Viton is selected for aggressive chemicals or higher temperatures. We guide you in choosing the optimal gasket for your application.Q: Where are these plate heat exchangers typically installed?

A: Our PHEs are installed in industrial plants, commercial buildings, marine vessels, and processing facilities across India. They can be frame-mounted for stable, reliable operation and are designed to integrate seamlessly within a facilitys existing piping and systems.Q: How is cleaning and maintenance of the PHE carried out?

A: Cleaning is simple due to easy plate removal and reassembly. The plate pack can be taken apart for mechanical scrubbing or chemical cleaning, ensuring hygiene and prolonged performance. Regular inspection and service prevent fouling and maximize efficiency.Q: What are the operational efficiency and pressure/temperature ratings of these exchangers?

A: Our plate heat exchangers deliver up to 95% thermal efficiency with flow rates up to 250 m/hr, pressures up to 25 bar, and operating temperatures from -10C to 180C, depending on model and materials chosen.Q: What benefits do modular and leak-proof construction provide?

A: The modular design allows for easy scalability and maintenance, while leak-proof construction minimizes product loss, enhances safety, and simplifies compliance with stringent process requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in food processing machines Category

Mixing Blending Tank

Weight : standard Kilograms (kg)

Condition : New

Shape : standard

Construction : Wire Mesh

Feature : Mixing Blending Tank (vessel)

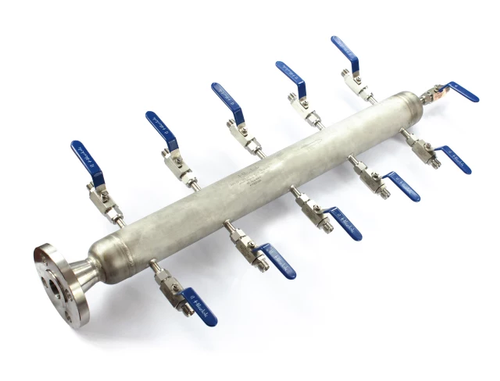

Air Distribution Headers

Weight : Depends on size and material

Condition : New

Shape : Round, Cylindrical

Construction : Other, Seamless Welded Construction

Feature : Uniform Air Distribution, Leak Proof Design, Corrosion Resistant

Connecting Type : Other, Flanged, Threaded, Welded

DUMP TANK

Weight : Depends on capacity and diameter

Condition : New

Shape : Cylindrical (Vertical)

Construction : Other, Welded, Seamless

Feature : Easy to use, corrosion resistant, hygienic design

Connecting Type : Other, Triclover / Flanged / Customized

SKID MOUNTED MILK CHILLING SYSTEM

Weight : Approx. 300800 kg (depending on capacity)

Condition : New

Shape : Rectangular/Custom Skid layout

Construction : Other, Skid Mounted with robust stainless steel frame

Feature : Rapid chilling, compact skidmounted design, integrated cooling system, easy to install and operate, hygienic and easy to clean.

Connecting Type : Other, Triclamp/Flanged connections

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry