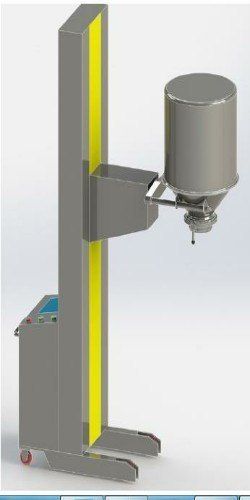

Moveable Hoist Bin Lifter

Moveable Hoist Bin Lifter Specification

- Usage & Applications

- Lifting and emptying bins into waste containers in hotels, hospitals, factories, food processing units, and industrial premises.

- Noise Level

- <70 dB

- Phase

- Single Phase

- Features

- Mobile with caster wheels, electric hoist operation, safety interlocks, heavy-duty construction, adjustable bin size support.

- Temperature

- Up to 50C operating ambient

- Frequency

- 50 Hz

- Type

- Moveable Hoist Bin Lifter

- Material

- Mild Steel

- Capacity

- 120-240 Litres

- Computerized

- No

- Control Mode

- Push Button / Pendant

- Voltage

- 220-240 V

- Power

- 1 HP

- Weight (kg)

- 50-100 kg

- Dimension (L*W*H)

- 1200 x 800 x 2000 mm

- Color

- Blue / Yellow

- Mobility

- Equipped with lockable castor wheels for easy transportation

- Lifting Height

- Up to 1500 mm

- Compatible Bin Types

- EN 840 wheelie bins, customized bins

- Installation

- Plug-and-play design, no permanent installation required

- Power Supply Cable Length

- 3 meters

- Finish

- Powder Coated

- Compliance

- Meets local safety and CE standards

- Safety Features

- Emergency stop switch, safety guard, and overload protection

- Operation Speed

- Approx. 3-5 bins/min (depending on size)

- Hoist Type

- Electric Chain Hoist

Moveable Hoist Bin Lifter Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Cheque, Letter of Credit (L/C), Paypal, Western Union, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, Central America, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Moveable Hoist Bin Lifter

Moveable Hoist Bin Lifter

Moveable Hoist / Bin Lifter Easy Moveable Loading, Unloading & Conveying process

Application & Process :

The Moveable hoist is use for transfer the material dust free and without human touch in pharmaceutical industries for Load powder in to RMG bowl, Load powder in to hopper of tablet press, Load tablet in to hopper of blister pack & Coating Machine and online sifting and milling as well as container one room to another room..The Drum Lifter consists of a main frame made of machined alloy steels. This flat make a "C" type basic structure. It is perfect in geometry and accuracy in terms of inside sliding width. Inside there is a carriage which runs on the rollers. These rollers run on ball bearings and are having a locking rim which allows rollers to glide smoothly inside the main frame and in straight line only. The load which is carried by the carriage moves upward without any bending or tilting. Rollers are made up of alloy steel having ball bearings and special rubber oil seal. The Structure is completely cladded / Covered by S.S.304 Sheets completely covering the structure and argon welded to avoid any screws for the cladding.This entire structure is supported at both the ends by moveable trolley mounting structure for easy mobility. Inside the main frame there is a hydraulic cylinder which lifts or lowers the pulley to which the carriage is connected. Hydraulic cylinder is actuated by double solenoid valve which can make it move upward and downward. One can raise lower or stop the load at desired position. Hydraulic cylinder is also having a flow control valve which controls the linear speed of the load.. There is a limit switch at the lower and upper ends which determines the endpoints for the lift and that can be set by the user as per their requirements. On the front side there is rubber /nylon sandwiched belt which is PVC coated on both sides and it covers the front side completely as the carriage moves upward or downward side. Thus entire hoist is covered from all sides allowing no tablet dust to enter inside. The hoist will have power pack kept on the service floor and hydraulic tubes will come through the main housing internally.

Salient Features :

Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Capacity available 30 Kg to 150 Kg. Fully automatic system, with hydraulic lifting arrangement for quick and easy handling & conveying. Limit switches are provided to stop the hydraulic drive when the stroke is competed. The hoist working height is suitable for 6 feet for door.

make it move upward and downward. One can raise lower or stop the load at desired position. Hydraulic cylinder is also having a flow control valve which controls the linear speed of the load.. There is a limit switch at the lower and upper ends which determines the endpoints for the lift and that can be set by the user as per their requirements. On the front side there is rubber /nylon sandwiched belt which is PVC coated on both sides and it covers the front side completely as the carriage moves upward or downward side. Thus entire hoist is covered from all sides allowing no tablet dust to enter inside. The hoist will have power pack kept on the service floor and hydraulic tubes will come through the main housing internally.

Salient Features :

Design is cGMP - Current Good Manufacturing Practices compliance.

All contact parts AISI 316 & non contact parts AISI 304.

Effortless Waste Handling in Every Setting

Designed for versatility, this bin lifter streamlines waste management in hotels, hospitals, factories, and food processing units. Its mobile, heavy-duty construction stands up to rigorous industrial demands, while compatibility with EN 840 and customizable bins accommodates various waste systems. Whether for continuous industrial use or for smaller operations, the device enhances workplace efficiency and hygiene by enabling one person to safely lift and tip bins with minimal effort.

Advanced Safety and Compliance Features

Safety is paramount, with built-in emergency stop switches, safety guards, and overload protection to minimize risks during operation. The hoist meets local safety and CE standards, reassuring users of reliable and secure performance. With its low operational noise (<70 dB) and safety-focused design, operators can confidently use the equipment in sensitive environments such as healthcare facilities and food production areas.

FAQ's of Moveable Hoist Bin Lifter:

Q: How does the Moveable Hoist Bin Lifter enhance waste handling efficiency?

A: The Moveable Hoist Bin Lifter automates the lifting and emptying process for wheelie bins, allowing users to process approximately 3-5 bins per minute. This significantly reduces manual handling, saves time, and lowers the risk of injury or spillage in settings like hotels, hospitals, and industrial sites.Q: What types of bins are compatible with this bin lifter?

A: It is compatible with standard EN 840 wheelie bins as well as a range of customized bins. Adjustable supports ensure secure lifting, accommodating bin capacities between 120 and 240 litres.Q: Where can the Moveable Hoist Bin Lifter be installed and used?

A: Its plug-and-play design requires no permanent installation, making it suitable for use anywhere on flat surfaces within hotels, factories, food processing units, hospitals, or any site where waste handling mobility is required.Q: What safety features does this bin lifter offer during operation?

A: This lifter is equipped with an emergency stop switch, safety guard, overload protection, and safety interlocks to protect both the operator and bystanders from potential hazards while operating the machine.Q: How is the bin lifter operated and powered?

A: Operation is easy with a push button or pendant control and a 1 HP electric chain hoist running on a single-phase supply (220-240 V, 50 Hz). It features a 3-meter power cable for flexible positioning.Q: What is the maintenance process for this equipment?

A: Routine maintenance involves checking the chain hoist, inspecting the safety features, lubricating moving parts, and ensuring that the powder-coated finish remains intact. Cleaning and periodic inspection will maintain optimal performance and longevity.Q: What are the primary benefits of using this moveable hoist bin lifter?

A: By mechanizing bin handling, the lifter minimizes manual labor, reduces injury risk, improves workplace hygiene, and raises productivity. Its durable build and mobility make it an ideal investment for high-demand waste management environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

Pharmaceutical Planetary Mixer

Minimum Order Quantity : 01 Piece

Control Mode : Other, SemiAutomatic / Manual

Color : Silver

Capacity : 50 to 1000 Liters

Computerized : No

Material : Stainless Steel (SS304/SS316)

Automatic Hand Sanitizer Machine

Control Mode : Other, Sensor Operated

Color : Silver

Capacity : 5 Liters

Computerized : No

Material : Stainless Steel Body

Bin Loader

Control Mode : Automatic

Color : Silver

Capacity : 50200 kg/h (customizable)

Computerized : No

Material : Stainless Steel

Vacuum Homogenizer / Emulsion Mixer

Control Mode : Automatic

Color : Silver

Capacity : 100 Liters

Computerized : Yes

Material : Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry